Natural silk micro-nanofiber composite porous material and application thereof

A technology of micro-nano fiber and natural silk, which is applied in the field of porous materials, can solve the problems of being unable to be used as tissue engineering scaffold materials, airgel porous materials are unstable when exposed to water, and limited structural control, etc., and achieve high porosity and dust holding capacity High, low filter resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

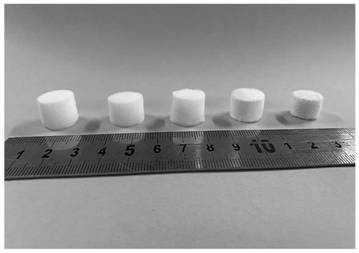

[0047] A kind of natural silk micro-nano fiber composite porous material is prepared through the following steps:

[0048] (1) Put 5g of degummed silk into swelling solution (a mixed solution of calcium nitrate, ethanol and water, the volume ratio of ethanol and water is 1:3, and the content of calcium nitrate is 5g:100mL) and place it in 60 ℃ oven for 24 hours, after taking it out, wash it with deionized water for 3 times, place it in a crusher with a cutter head speed of 8000r / min at a bath ratio of 1:150g / mL, and mechanically treat it for 60 minutes to obtain silk micro-nano fiber suspension.

[0049] (2) Chitosan was dissolved in 1% acetic acid solution, the rotating speed of the magnetic stirrer was 300 rpm, and stirred for 4 hours to obtain a chitosan solution with a concentration of 5 mg / mL.

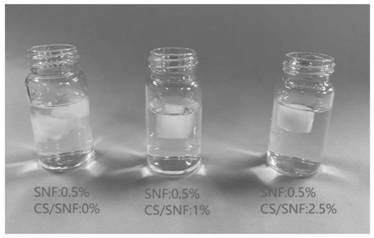

[0050] (3) Add 0.5g of dry silk micro-nanofibers and 1mL of chitosan solution with a concentration of 5mg / mL into 99mL of deionized water, mix in a homogenizer at 800rpm for 30min...

Embodiment 2

[0052] A kind of natural silk micronanofiber composite porous material, compared with embodiment 1, difference is that in step (3), 0.5g dry state silk micronanofiber and 2.5mL concentration are chitosan of 5mg / mL The solution was added into 97.5 mL of deionized water, and mixed for 30 min in a homogenizer with a rotating speed of 800 rpm, and the mass concentration of the total solute after mixing was 0.5125%. Others are substantially the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0054] A natural silk micro-nano fiber composite porous material. Compared with Example 1, the difference is that in step (3), it is pre-frozen in liquid nitrogen for 30 minutes, and the frozen sample is taken out and placed at -50°C for 72 hours of freeze-drying. Others are substantially the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com