Preparation method of high-dispersion carbon nanotube material

A technology of carbon nanotubes and high dispersion, applied in the direction of carbon nanotubes, nanocarbons, etc., can solve problems such as easy agglomeration, hindering performance, and inability to achieve dispersion, and achieve the effect of solving agglomeration, easy operation, and convenient and effective preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

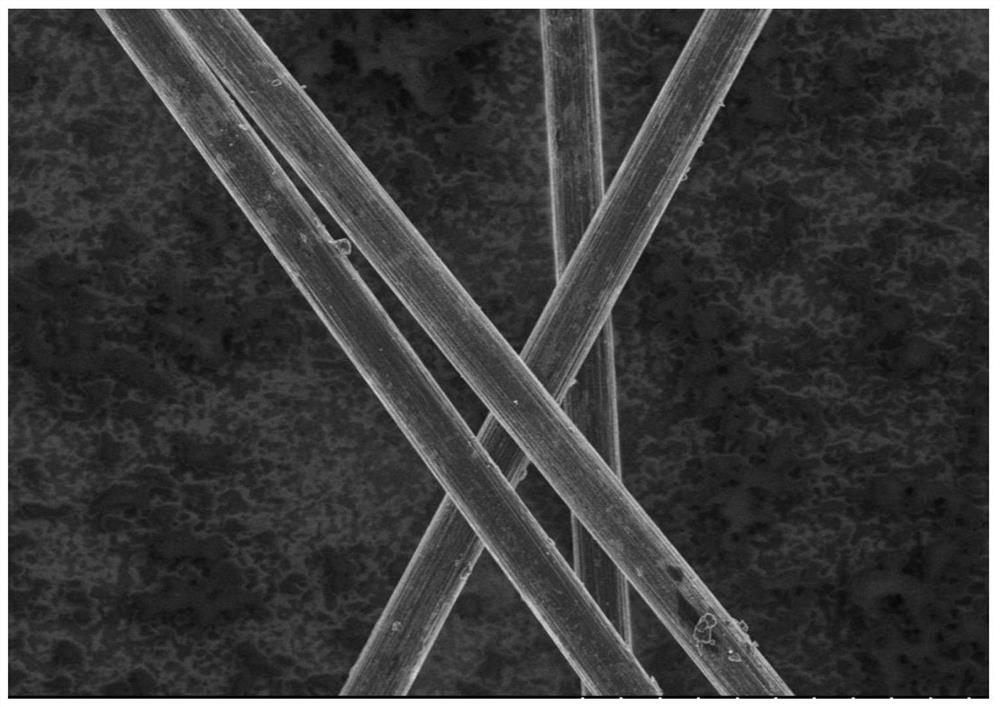

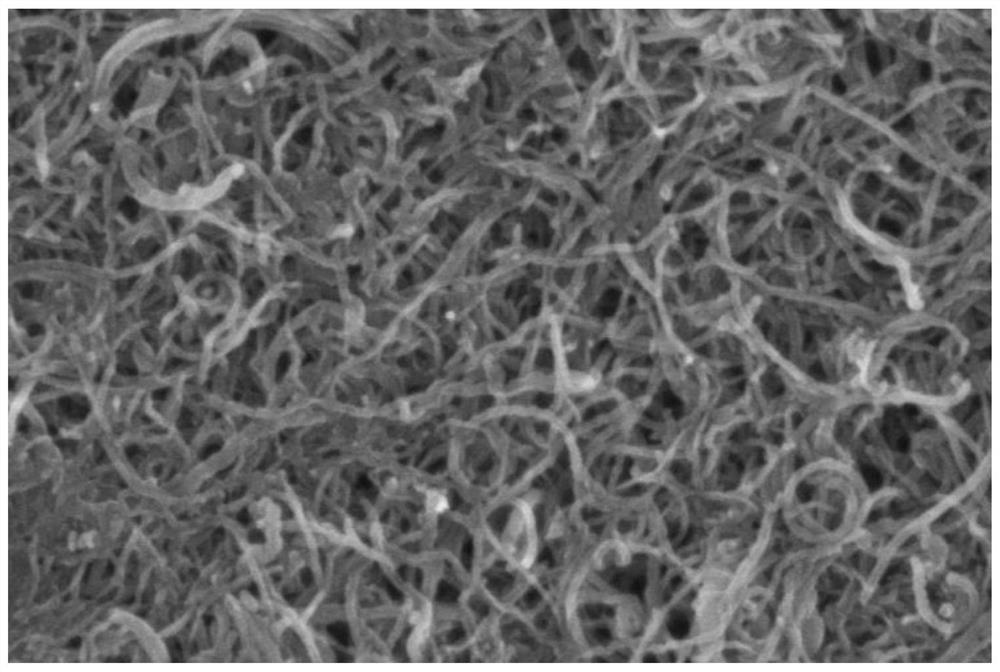

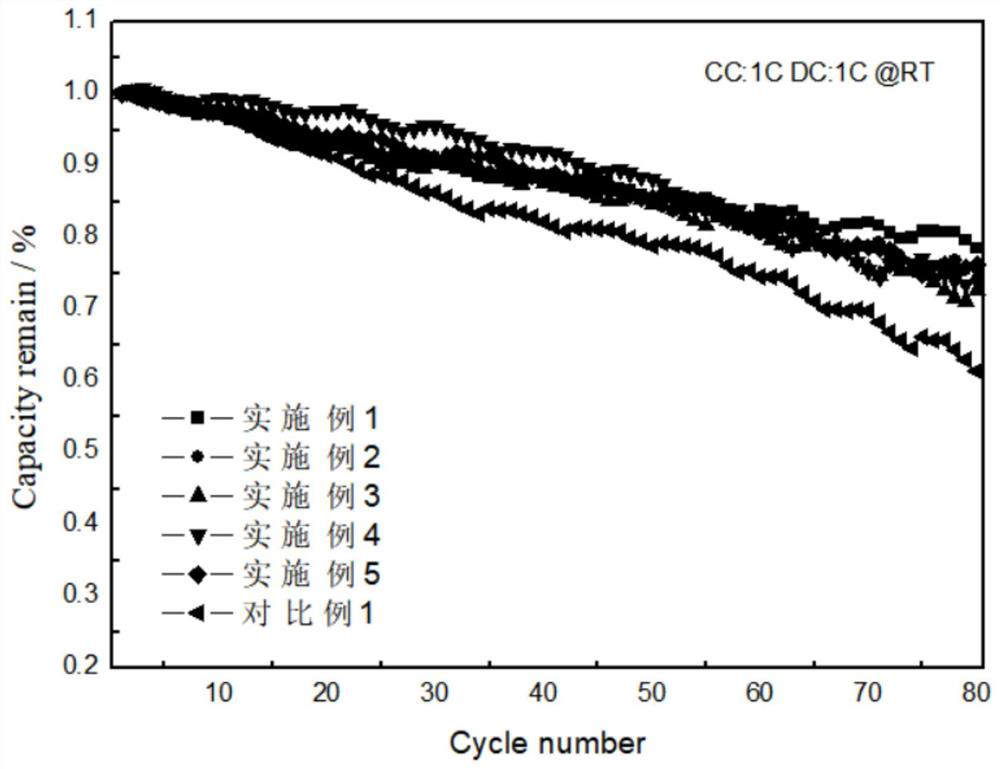

[0026] Metal salt ferric nitrate and aluminum nitrate are added to water according to the mass ratio of 1:1 to configure an aqueous solution with a metal salt mass concentration of 50%, and then the solution and asphalt mixture are mixed according to the mass ratio of 1:1 for spinning. The filament temperature was 150°C and the time was 14 minutes. Then carry out preoxidation and carbonization, the temperature is 220 ℃, the time is 60 minutes. The carbonized spun carbon fiber is pulverized and passed through a 150-mesh sieve. After sieving, put the pulverized carbon fibers into a tube furnace, heat up to 680°C with nitrogen gas, and then keep warm for 50 minutes. During the heat preservation, pass propylene gas. The volume ratio of propylene and nitrogen is 2:1. After the heat preservation is completed, turn off the heating. Stop passing propylene, continue to pass nitrogen, wait to be cooled to room temperature and take out the carbon nanotube material prepared by reaction, ...

Embodiment 2

[0028] Metal salt ferric nitrate and aluminum nitrate are added to water according to the mass ratio of 1:2 to configure an aqueous solution with a metal salt mass concentration of 50%, and then the solution and asphalt mixture are mixed according to the mass ratio of 1:1 for spinning. The filament temperature was 150°C and the time was 14 minutes. Then carry out preoxidation and carbonization, the temperature is 220 ℃, the time is 60 minutes. The carbonized spun carbon fiber is pulverized and passed through a 150-mesh sieve. After sieving, put the pulverized carbon fibers into a tube furnace, heat up to 680°C with nitrogen gas, and then keep warm for 50 minutes. During the heat preservation, pass propylene gas. The volume ratio of propylene and nitrogen is 1:1. After the heat preservation is completed, turn off the heating. Stop passing propylene, continue to pass nitrogen, wait to cool to room temperature and take out the carbon nanotube material prepared by the reaction. ...

Embodiment 3

[0030] Add metal salts of ferric nitrate, cobalt nitrate and aluminum nitrate to water in a mass ratio of 1:1:4 to prepare an aqueous solution with a metal salt mass concentration of 50%, and then mix the solution with an asphalt mixture in a mass ratio of 1:1 Spinning was carried out at a spinning temperature of 150° C. for 14 minutes. Then carry out preoxidation and carbonization, the temperature is 220 ℃, the time is 60 minutes. The carbonized spun carbon fiber is pulverized and passed through a 150-mesh sieve. After sieving, put the pulverized carbon fibers into a tube furnace, heat up to 680°C with nitrogen gas, and then keep warm for 50 minutes. During the heat preservation, pass propylene gas. The volume ratio of propylene and nitrogen is 2:1. After the heat preservation is completed, turn off the heating. Stop passing propylene, continue to pass nitrogen, wait to cool to room temperature and take out the carbon nanotube material prepared by the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com