Preparation method of cement-based paraffin phase change energy storage material

A phase change energy storage material and a phase change material technology, which are applied in the field of phase change energy storage building materials, can solve the problems of unfavorable large-scale popularization and application, uneven distribution of thickness of calcium carbonate wall materials, etc. The effect of small influence and easy pouring and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

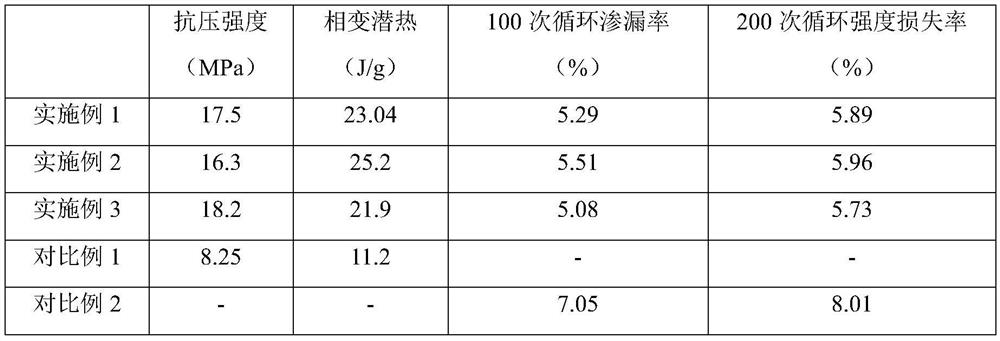

Examples

Embodiment 1

[0023] 1) Mix Span-80 and Tween-80 to prepare an emulsifier with an HLB of 10;

[0024] 2) Heat and melt 45g of paraffin and 22.5g of emulsifier in a water bath, then add 157.5g of water at a temperature of 80°C to the melt in a colloid mill with a stirring speed of 1000r / min to prepare an oil-in-water emulsion, and continue stirring for 40min to ensure sufficient Emulsification, the emulsification rate reaches 100%, and the average particle size of the paraffin phase particles is about 0.9 μm;

[0025] 3) Stir 500g of ordinary Portland cement (P.O 52.5) cement, 0.75g of polycarboxylate superplasticizer, 42.5g of water and 225g of oil-in-water paraffin emulsion and pour them into shape. Emulsion-based cement-based phase-change energy storage materials.

Embodiment 2

[0027] 1) Mix Span-20 and Tween-20 to prepare an emulsifier with an HLB of 12;

[0028] 2) Heat and melt 55g of paraffin and 22g of emulsifier in a water bath, then add 143g of water at a temperature of 75°C to the melt in a colloid mill with a stirring speed of 800r / min to prepare an oil-in-water emulsion, and keep stirring for 50min to ensure full emulsification. The emulsification rate reaches 93.2%, and the average particle size of the paraffin phase particles is about 1.2 μm;

[0029] 3) Stir 500g of ordinary Portland cement (P.O 52.5) cement, 0.5g of naphthalene-based superplasticizer, 47g of water, and 220g of oil-in-water paraffin emulsion, and pour them into shapes. The standard curing is 28 days, and the oil-in-water emulsion is prepared. Cement-based phase change energy storage materials.

Embodiment 3

[0031] 1) Mix Span-20 and Tween-20 to prepare an emulsifier with an HLB of 10;

[0032] 2) Heat and melt 35g of paraffin and 15g of emulsifier in a water bath, then add 102g of water at a temperature of 75°C to the melt in a colloid mill with a stirring speed of 1100r / min to prepare an oil-in-water emulsion, and keep stirring for 35min to ensure full emulsification. The emulsification rate reaches 90.2%, and the average particle size of the paraffin phase particles is about 1.5 μm;

[0033] 3) Stir 500g of ordinary Portland cement (P.O 52.5) cement, 1g of SMF superplasticizer, 108g of water and 152g of oil-in-water paraffin emulsion and pour them into shape. The standard curing is 28 days, and the cement-based oil-in-water emulsion is obtained. Phase change energy storage materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com