Preparation process of flame-retardant low-density polyethylene

A low-density polyethylene and preparation technology, applied in the field of adhesives, can solve the problems of poor mechanical strength, low heat resistance, poor permeability, etc., achieve good use requirements, excellent flame retardant performance, and meet the effects of flame retardant requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments.

[0019] This embodiment provides a preparation process of flame-retardant low-density polyethylene, comprising the following steps,

[0020] a. Select 100 parts of ethylene with a purity ≥ 99% as a raw material, add 0.5 to 1 part of a peroxide initiator at a pressure of 100 to 300 MPa and a temperature of 200 to 300 ° C, and carry out a polymerization reaction in a reactor; the materials coming out of the reactor,

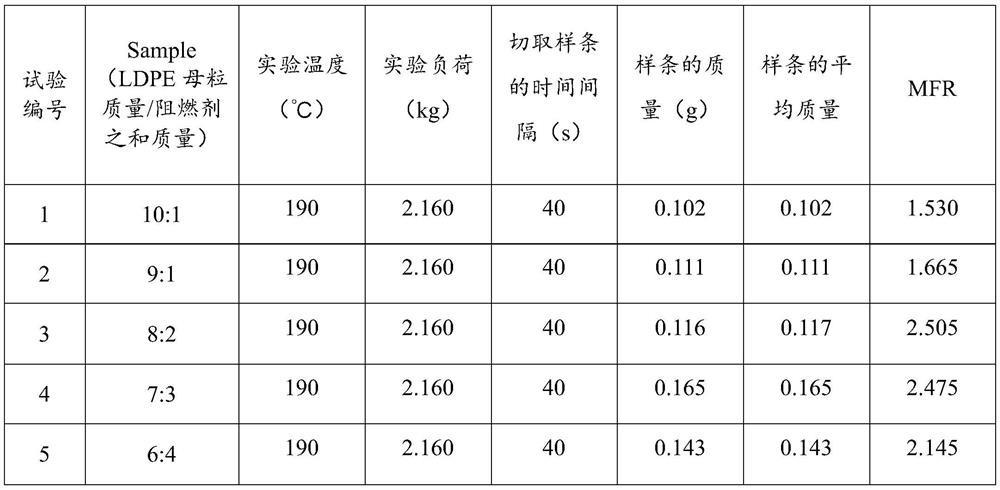

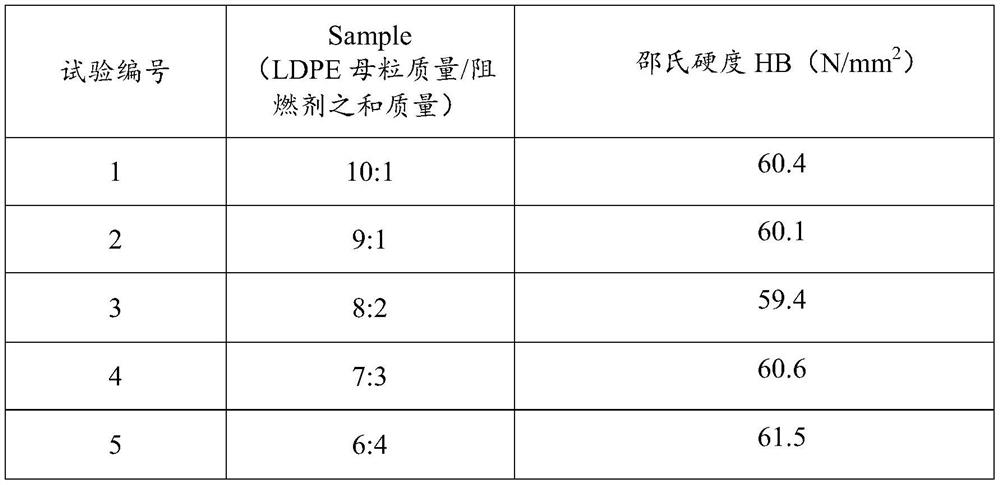

[0021] b. Select 100 parts of high-purity polyethylene particles with a melt index of 0.1 to 2.5 g / min from the materials coming out of the reactor, and add them into a twin-screw mixing extruder with a twin-roller temperature of 120°C-130°C, and wait until After the particles are completely melted and covered with rolls, add 10-45 parts of the first flame retardant, 1-23 parts of the second flame retardant, and finally add 0.1-0.2 parts of the initiator for mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com