Ultraviolet curing transfer printing adhesive composition for microprism reflective film as well as preparation method and application of ultraviolet curing transfer printing adhesive composition

A reflective film, microprism technology, applied in the direction of copying/marking method, printing, adhesive, etc., can solve the problems of low reflectivity and difficult demoulding, and achieve the effect of high reflectivity, good demoulding effect and improving reflectance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the ultraviolet curing transfer adhesive composition of following embodiment and comparative example, comprises the steps:

[0039] Stir epoxy acrylic resin, bisphenol fluorenyl urethane acrylate, photopolymerizable monomer, photoinitiator and fluorine-modified polymer or monomer until uniform, and filter to obtain microprism reflective film with UV curing transfer printing glue composition. The stirring speed is 1200 rpm, and the stirring time is 1.5h.

Embodiment 1~5

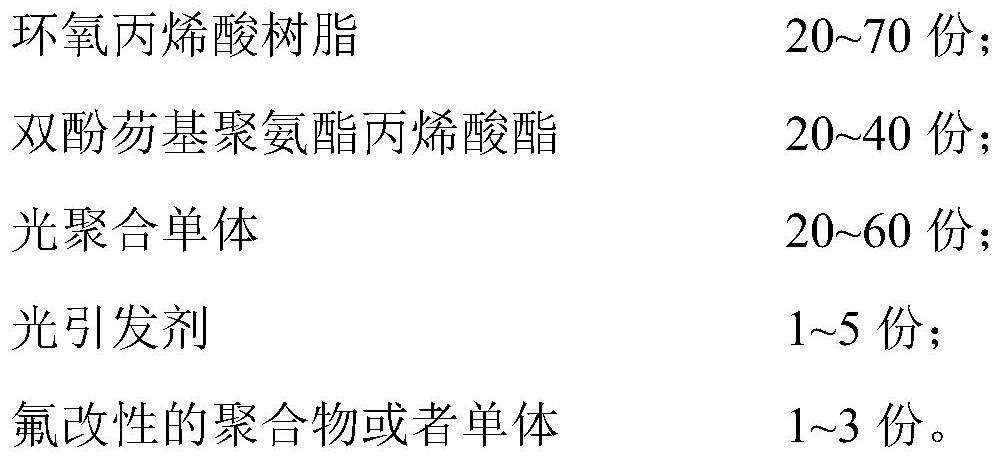

[0041] Examples 1-5 provide a series of UV-curable transfer adhesive compositions, and the contents of specific components are shown in Table 1.

[0042] The component content (part) of table 1 embodiment 1~5

[0043]

Embodiment 6~8 and comparative example 1~4

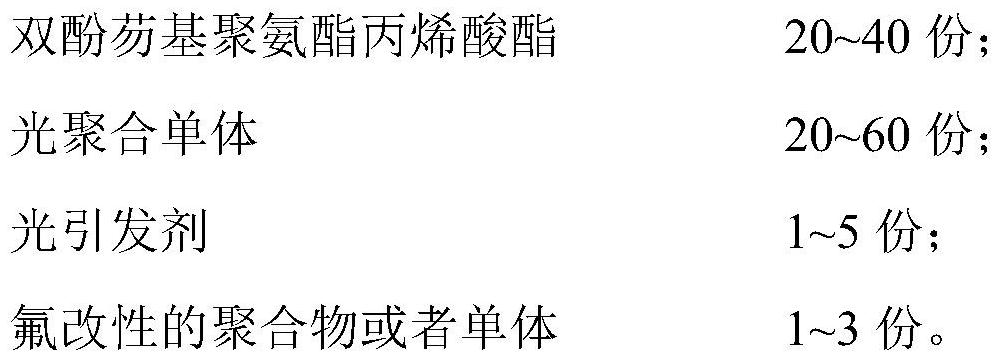

[0045] Examples 6-8 and Comparative Examples 1-4 provide a series of UV-curable transfer adhesive compositions, and the contents of specific components are shown in Table 2.

[0046] The component content (part) of table 2 embodiment 6~8 and comparative example 1~4

[0047]

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com