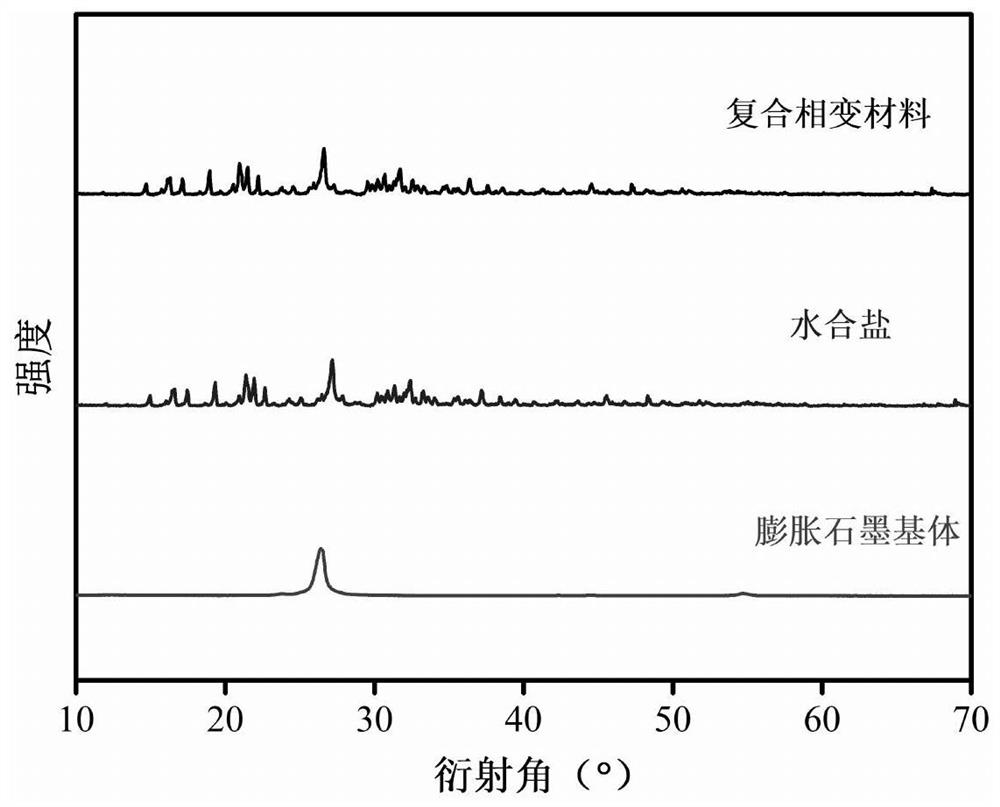

Method for enhancing stability of expanded graphite-based inorganic hydrated salt composite phase change material

A technology of composite phase change materials and inorganic hydrated salts, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problem of unstable heat storage performance, poor adsorption performance of inorganic hydrated salts, packaging of composite shaped phase change energy storage materials The amount cannot be further improved to achieve the effects of adsorption, surface tension reduction and wettability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for enhancing the stability of expanded graphite-based inorganic hydrated salt composite phase-change materials, comprising the following steps:

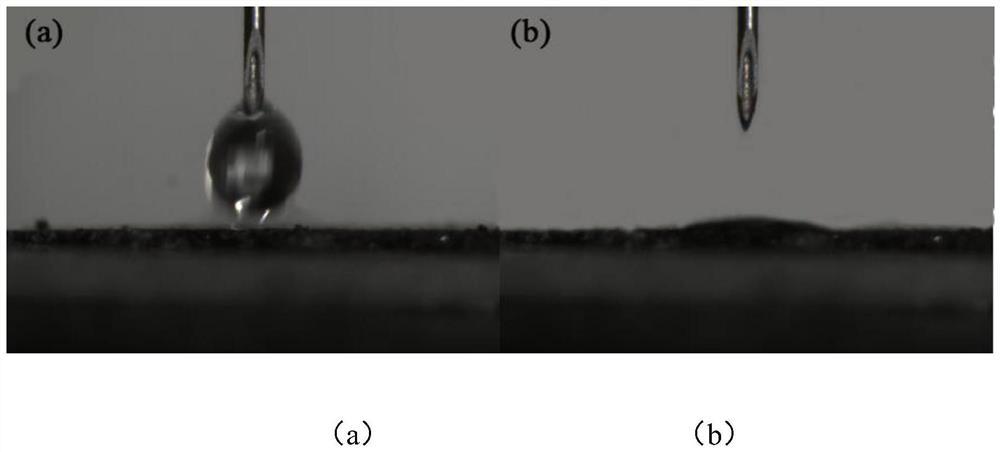

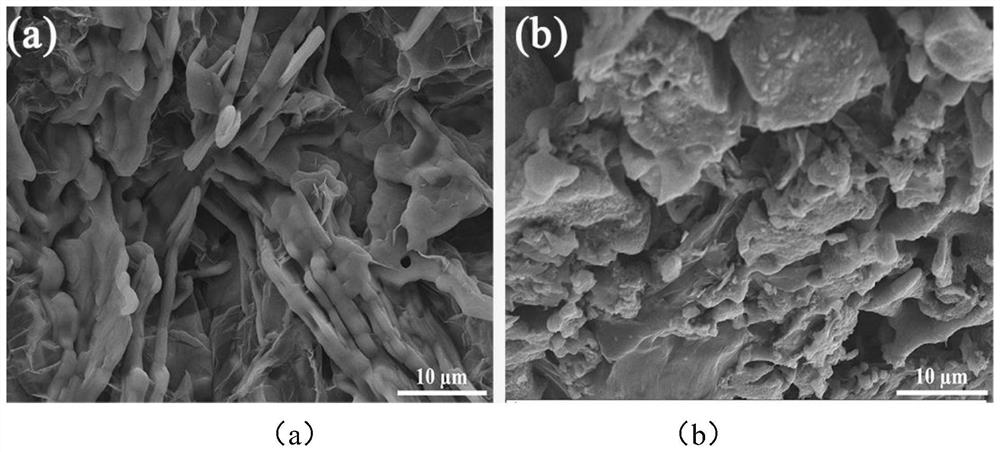

[0034] (1) the cetyltrimethylammonium chloride of 6 mass parts is dissolved in the ethanol solution of 80 mass parts, obtain the dehydrated alcoholic solution of cetyltrimethylammonium chloride, put 3 mass parts Expanded graphite was added to the dehydrated ethanol solution of cetyltrimethylammonium chloride for vacuum ultrasonic impregnation for 5min;

[0035] (2) Dry the impregnated sample in an oven at 50°C until the quality of the sample is stable and there is no obvious alcohol taste, and the expanded graphite hydrophilic modified packaging matrix is obtained;

[0036] (3) Submerge the packaging substrate in excess disodium hydrogen phosphate dodecahydrate (i.e., hydrated salt) solution for 5 minutes under the conditions of vacuum, 300W ultrasonic, and 50°C immersion, so that the hydrated salt can completely e...

Embodiment 2

[0043] A method for enhancing the stability of expanded graphite-based inorganic hydrated salt composite phase-change materials, comprising the following steps:

[0044] (1) the cetyl trimethyl ammonium chloride of 3 mass parts is dissolved in the ethanolic solution of 80 mass parts, obtain the dehydrated alcoholic solution of cetyl trimethyl ammonium chloride, put 3 mass parts of Expanded graphite is added to the dehydrated ethanol solution of cetyltrimethylammonium chloride and vacuum ultrasonically impregnated for 10min;

[0045] (2) Dry the impregnated sample in an oven at 60°C until the quality of the sample is stable and there is no obvious alcohol taste, and the expanded graphite hydrophilic modified packaging matrix is obtained;

[0046] (3) Submerge the packaging substrate in excess disodium hydrogen phosphate dodecahydrate solution for 5 minutes under vacuum, 400W ultrasonic, and 50°C immersion conditions, so that the hydrated salt can completely enter the pore struc...

Embodiment 3

[0050] A method for enhancing the stability of expanded graphite-based inorganic hydrated salt composite phase-change materials, comprising the following steps:

[0051] (1) The cetyltrimethylammonium chloride of 1 mass part is dissolved in the ethanolic solution of 80 mass parts, obtain the dehydrated alcoholic solution of cetyltrimethylammonium chloride, put 3 mass parts Expanded graphite was added to the dehydrated ethanol solution of cetyltrimethylammonium chloride for vacuum ultrasonic impregnation for 15 minutes;

[0052] (2) Dry the impregnated sample in an oven at 70°C until the quality of the sample is stable and there is no obvious alcohol taste, and the expanded graphite hydrophilic modified packaging matrix is obtained;

[0053] (3) Submerge the packaging substrate in excess disodium hydrogen phosphate dodecahydrate solution for 5 minutes under vacuum, 500W ultrasonic, and immersion conditions at 50°C, so that the hydrated salt can completely enter the pore struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| latent heat | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com