Solid electrolyte membrane, method for manufacturing same, and method for selecting solid electrolyte membrane

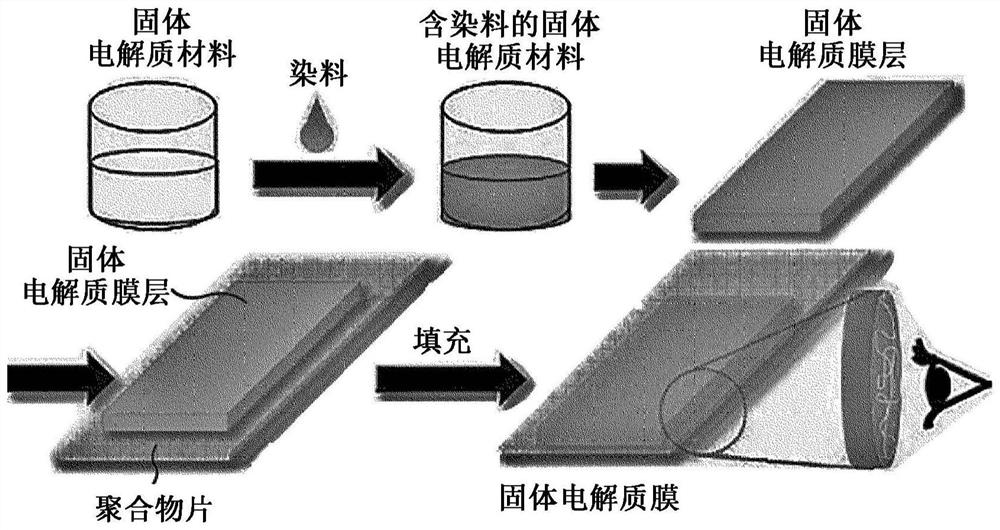

A solid electrolyte membrane, solid electrolyte technology, applied in solid electrolyte, non-aqueous electrolyte storage battery, electrolyte and other directions, can solve problems such as difficult to visually determine, difficult to determine the pores of porous sheet solid electrolyte material fully filled, etc., to reduce manufacturing costs, The effect of easy deformation and excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

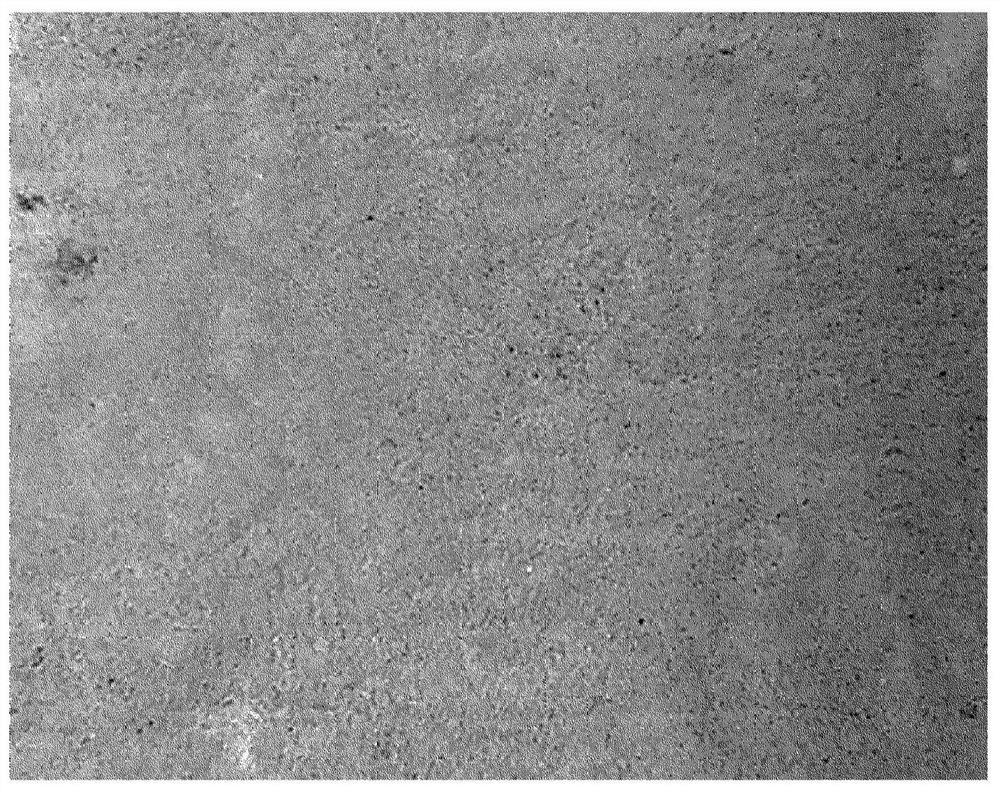

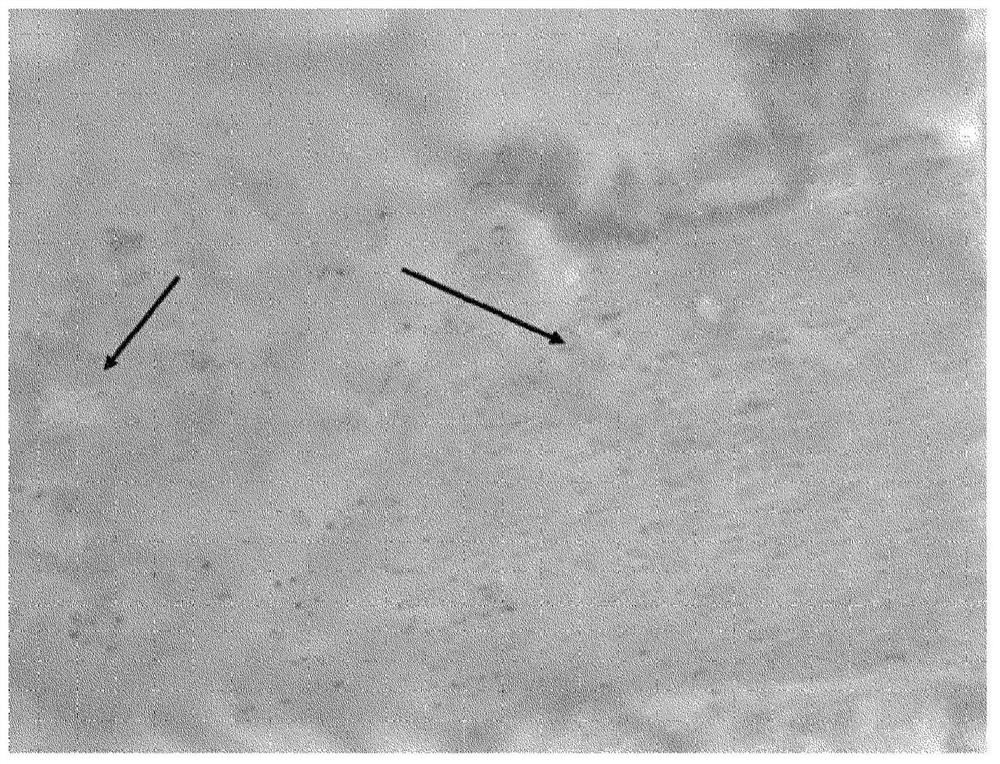

[0088] First, polyethylene oxide (PEO, Mw=4,000,000 g / mol) was dissolved in acetonitrile (AN) as a solvent to prepare a polymer solution having a concentration of 4% by weight. Here, LiTFSI as a lithium salt is further introduced such that [EO] / [Li + ] may be in a molar ratio of 18 / 1. The polymer solution was stirred overnight at 70° C. so that the PEO and lithium salt could be fully dissolved therein. Next, an additive solution containing an initiator and a curing agent is prepared. Curing agent is PEGDA (Mw=575), initiator is benzoyl peroxide (BPO), wherein the consumption of polyethylene diacrylate (PEGDA) is 20% by weight (based on PEO), and the consumption of BPO is 1% (based on PEGDA), and acetonitrile was used as solvent. The additive solution was stirred for about 1 hour so that the ingredients introduced therein could be thoroughly mixed. Then, add the additive solution to the polymer solution and mix it thoroughly. After that, 10 μL of commercially available fou...

Embodiment 2

[0090] A solid electrolyte membrane layer and a porous nonwoven web were prepared in the same manner as in Example 1. The solid electrolyte membrane layer is placed on a porous nonwoven web (87% porosity, 40 μm in thickness), and pressed at 25° C. by roll pressing, so that the solid electrolyte membrane layer can be pressed into the porous nonwoven web . In this way, a solid electrolyte membrane is obtained comprising a solid electrolyte membrane layer integrated with a porous nonwoven web. The solid electrolyte membrane has a thickness of about 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com