Vertical double-layer filter cloth circulating filter pressing system and filter pressing method thereof

A filter cloth and double-layer technology, which is applied in the double-layer filter cloth circulation system and its press filter field, can solve the problems of low efficiency in the mud cake treatment process, low water content of sludge, high water content of mud cake, etc., and achieve a good market economy Benefit, low sludge moisture content, low sludge moisture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

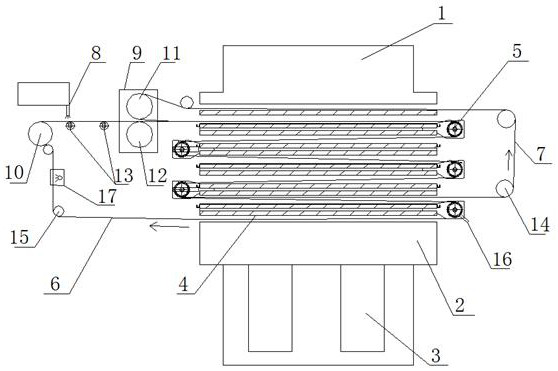

[0045] as attached figure 1 A vertical double-layer filter cloth circulating filter press system is shown, which includes a frame, which is equipped with a double-layer filter cloth circulation mechanism, a filter plate group, an upper pressing plate 1, a lower pressing plate 2, a hydraulic cylinder 3, an upper pressing plate 1. The lower platen 2 and the hydraulic cylinder 3 are connected to the frame, the upper end of the filter plate group is connected to the upper platen 1, the lower end is connected to the lower platen 2, the hydraulic cylinder 3 is connected to the upper platen 1 or the lower platen 2, and the hydraulic cylinder 3 operates , the upper platen 1 and the lower platen 2 are close to each other;

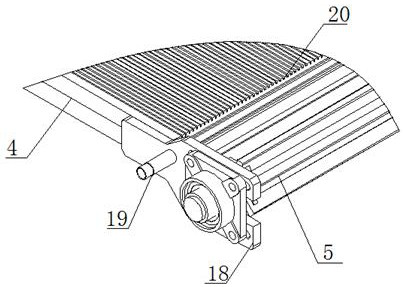

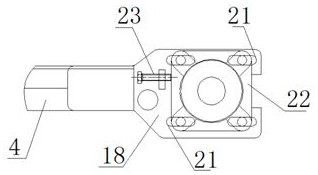

[0046] The filter plate set includes a plurality of filter press plates 4, the filter press plates 4 are horizontally arranged between the upper press plate 1 and the lower press plate 2 and are parallel to them, one end of the filter press plate 4 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com