Cobaltosic oxide ozone catalyst for degrading refractory pharmaceutical wastewater and application

A technology for tricobalt tetroxide and pharmaceutical wastewater, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst activation/preparation, etc. It can solve the problem of secondary pollution of catalysts that are difficult to recycle and achieve excellent results Catalytic activity, good removal rate, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

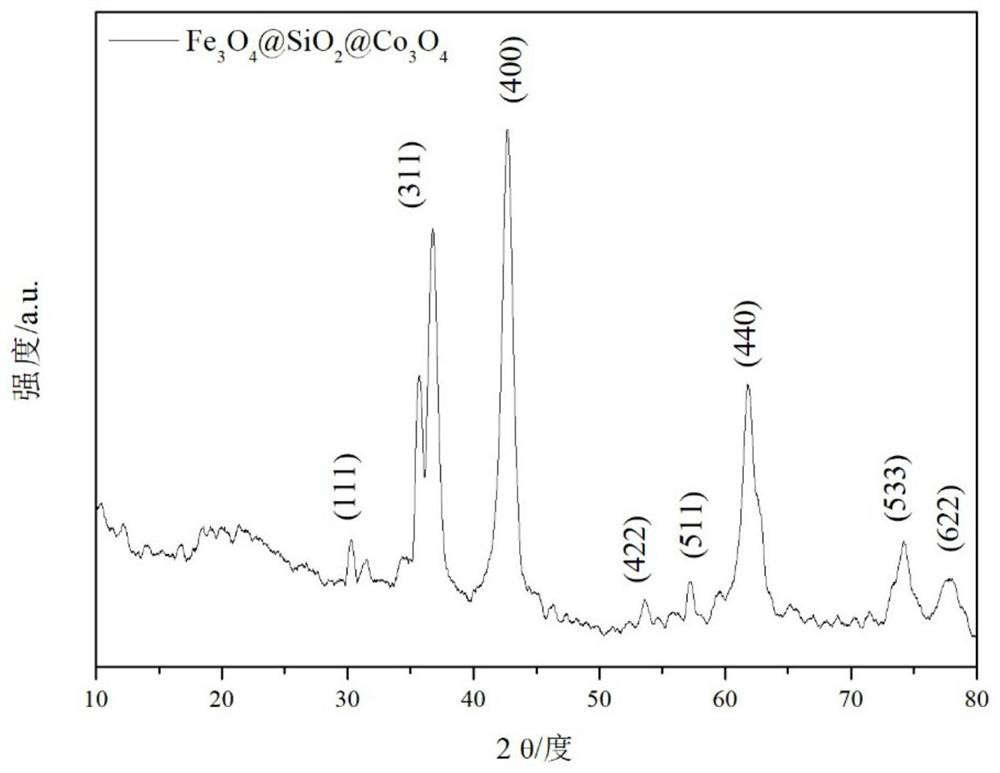

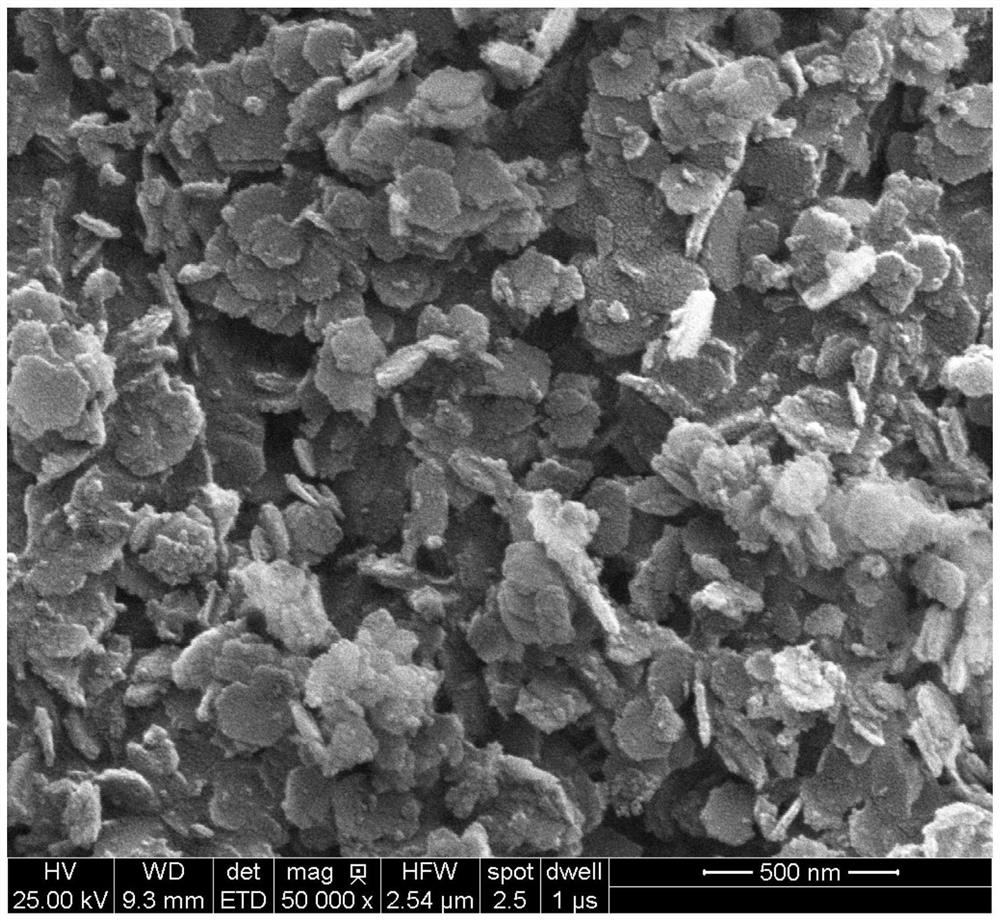

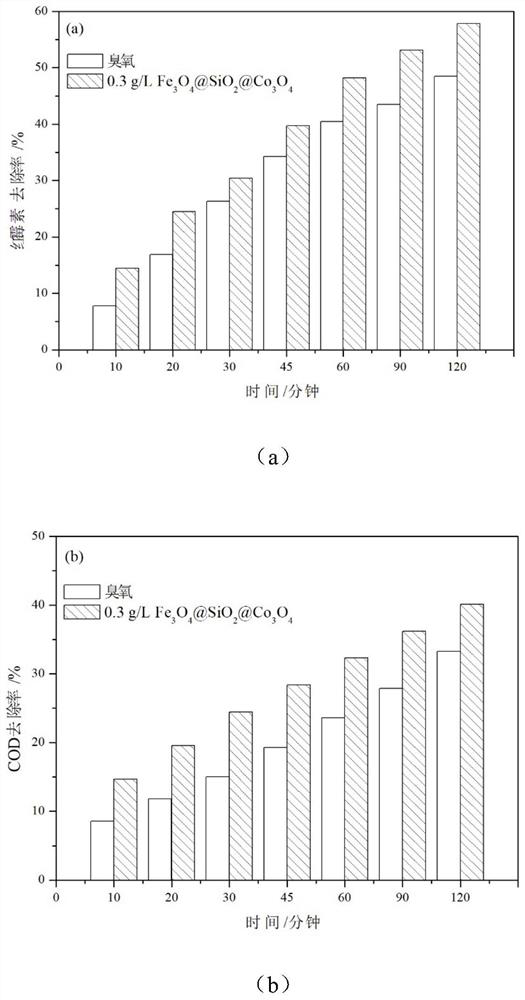

[0023] The invention provides a kind of tricobalt tetroxide ozone catalyst Fe 3 o 4 @SiO 2 @Co 3 o 4 The preparation method specifically comprises the following steps:

[0024] (1) 10.1gKNO 3 and 5.6g KOH were dissolved in 400mL of deoxygenated deionized water, and 100mL of 0.2mol / L FeSO 4 solution, accompanied by nitrogen protection. After 4 hours of stirring, the black precipitate was separated by centrifugation and washed three times with ethanol and deionized water respectively, the centrifugal speed was 8000rpm / min, and the time was 5min. It was dried in a vacuum oven at 60°C for 24h, ground and sieved to obtain Fe 3 o 4 particles.

[0025] (2) first the 1g nano-Fe obtained in step (1) 3 o 4The particles were added to 50 mL of 0.5 mol / L trisodium citrate dihydrate solution, and dispersed uniformly in the solution by ultrasound. Then, it was stirred for 6 hours in a water bath at 60° C. under nitrogen protection. The obtained black powder was separated by cent...

Embodiment 2

[0035] The invention provides a kind of tricobalt tetroxide ozone catalyst Fe 3 o 4 @SiO 2 @Co 3 o 4 The preparation method specifically comprises the following steps:

[0036] (1) 10.1gKNO 3 and 5.6g KOH were dissolved in 400mL of deoxygenated deionized water, and 100mL of 0.2mol / L FeSO 4 solution, accompanied by nitrogen protection. After 4 hours of stirring, the black precipitate was separated by centrifugation and washed three times with ethanol and deionized water respectively, the centrifugal speed was 8000rpm / min, and the time was 5min. It was dried in a vacuum oven at 70°C for 36h, ground and sieved to obtain Fe 3 o 4 particles.

[0037] (2) first the 1g nano-Fe obtained in step (1) 3 o 4 The particles were added to 50 mL of 0.5 mol / L trisodium citrate dihydrate solution, and dispersed uniformly in the solution by ultrasound. Then, it was stirred for 6 hours in a water bath at 60° C. under nitrogen protection. The obtained black powder was separated by cen...

Embodiment 3

[0046] The invention provides a kind of tricobalt tetroxide ozone catalyst Fe 3 o 4 @SiO 2 @Co 3 o 4 The preparation method specifically comprises the following steps:

[0047] (1) 10.1gKNO 3 and 5.6g KOH were dissolved in 400mL of deoxygenated deionized water, and 100mL of 0.2mol / L FeSO 4 solution, accompanied by nitrogen protection. After 4 hours of stirring, the black precipitate was separated by centrifugation and washed three times with ethanol and deionized water respectively, the centrifugal speed was 8000rpm / min, and the time was 5min. It was dried in a vacuum oven at 80°C for 48h, ground and sieved to obtain Fe 3 o 4 particles.

[0048] (2) first the 1g nano-Fe obtained in step (1) 3 o 4 The particles were added to 50 mL of 0.5 mol / L trisodium citrate dihydrate solution, and dispersed uniformly in the solution by ultrasound. Then, it was stirred for 6 hours in a water bath at 60° C. under nitrogen protection. The obtained black powder was separated by cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com