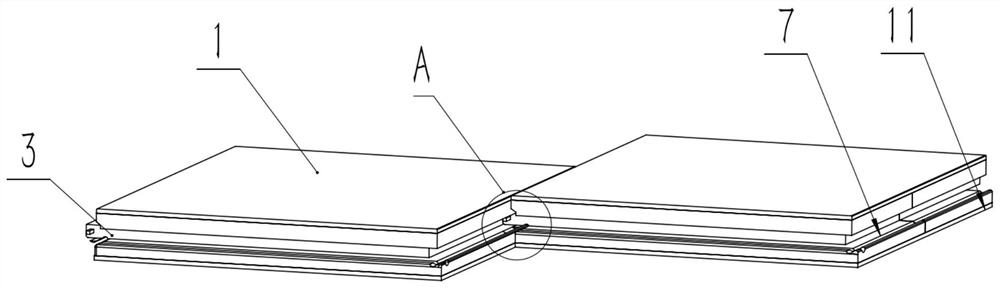

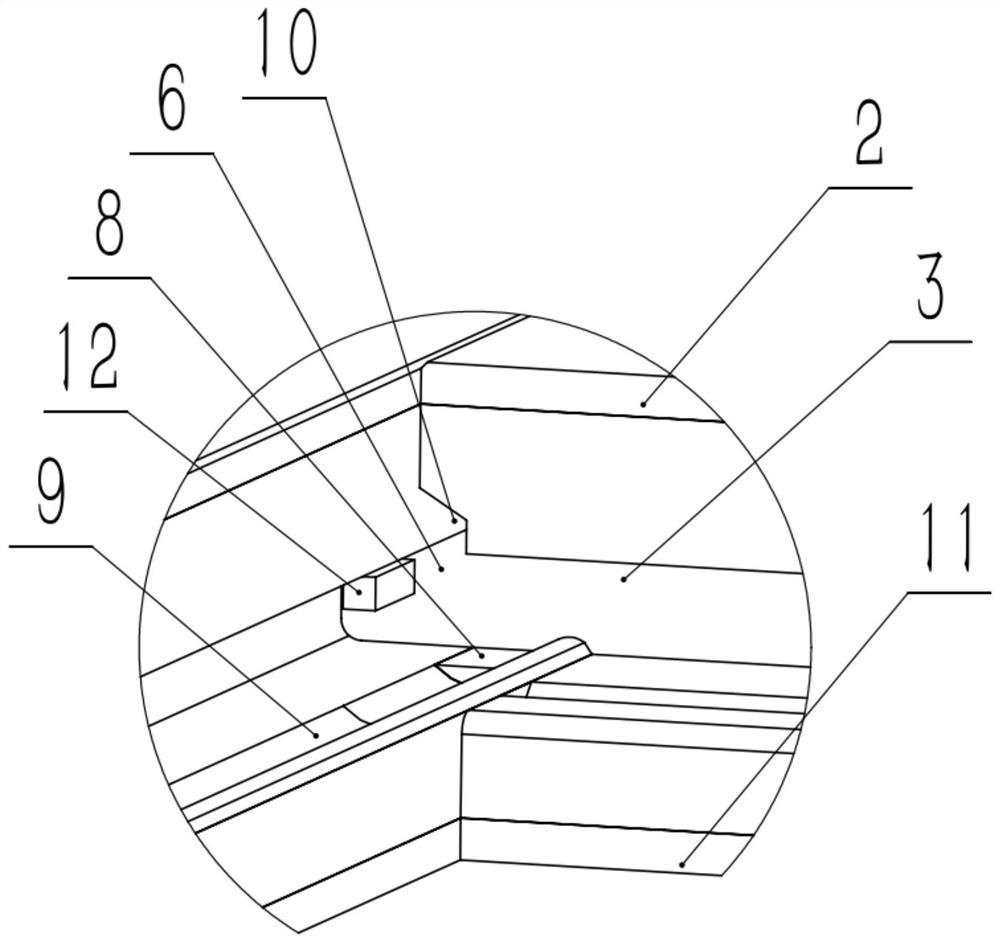

Seamlessly-connected antifouling solid wood floor preparation process and solid wood floor thereof

A solid wood floor and seamless connection technology, which is applied in the field of floor manufacturing, can solve problems such as insufficient adhesion of paint surface, impact on sanitation environment, and garbage cannot be cleaned, and achieve the effect of solving paint explosion, improving economic benefits, and improving antifouling indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A seamlessly connected anti-polluting solid wood floor preparation process, including the following steps:

[0044] (1) Select the raw material including the solid wood floor, the density of 0.75 g / cm3, the wood texture is clear, the coated effect is high, and the aqueous content of the sheet is 6%.

[0045] (2) Press the solid wood plate to heat the sheet, the sheet material is flat, the heat pressure temperature is 70 ° C, the treatment time is 80 minutes, and the extrusion pressure is 180 MPa.

[0046] (3) Place the sheet on the flat tray to be stacked, the stacked time is 12 hours.

[0047] (4) The forming slab is formed to make a plate material having a thickness of 12 mm, wherein the sand cut is 0.25 to 0.3 mm, and the sand back cut is 0.3-0.35 mm.

[0048] (5) Sloth the plates in four sides, and the groove is formed with a lock structure.

[0049] (6) The surface of the sheet is aqueous UV plant paint for sponge roller coating, single roller once, the coating amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com