High-TDS-content and high-silicon-dioxide-content scale inhibition and dispersion agent for reverse osmosis inflow and preparation method of scale inhibition and dispersion agent

A technology of scale inhibitor and dispersant, silica, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. Large amount and other problems, to achieve good effect of scale inhibition and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

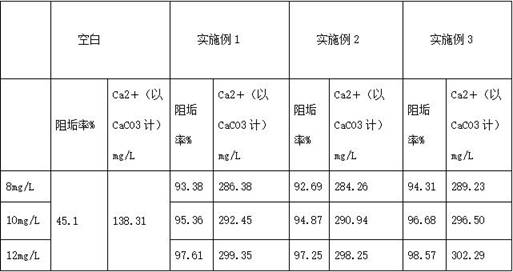

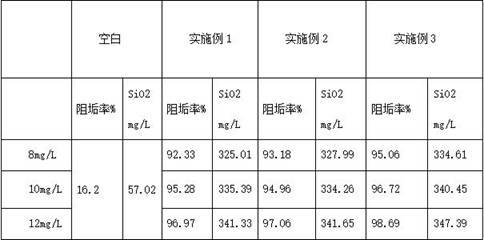

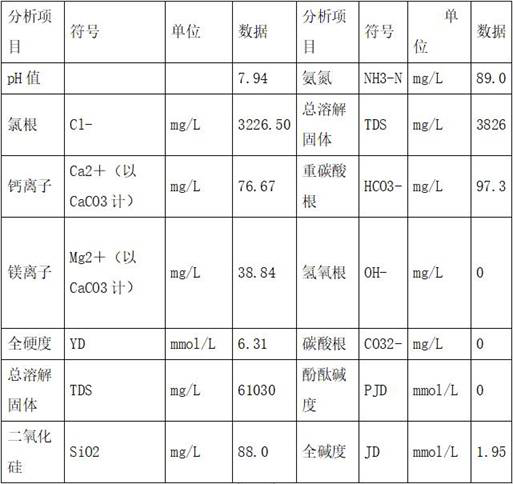

Examples

Embodiment 1

[0031] A reverse osmosis influent high TDS content, high silicon dioxide antiscaling dispersant, comprising the following components by mass percentage:

[0032] Polyamino polyether methylene phosphonic acid 25%

[0033] Amino acid methylene phosphonic acid 15%

[0034] Polymaleic anhydride 12%

[0035] Acrylic acid - hydroxypropyl acrylate copolymer 13%

[0036] A kind of preparation method of reverse osmosis feed water containing high TDS, high silicon dioxide antiscaling dispersant as above, comprises the following steps,

[0037] Step 1: Weighing polyamino polyether group methylene phosphonic acid, amino acid methylene phosphonic acid, polymaleic anhydride, acrylic acid-hydroxypropyl acrylate copolymer in sequence by mass percentage;

[0038] Step 2: Amino-terminated polyether and phosphorous acid are added to the reactor at a molar ratio of 1:4, and sulfuric acid with a mass fraction of phosphorous acid of 7% and partially demineralized water are added;

[0039] Step ...

Embodiment 2

[0043] A reverse osmosis influent high TDS content, high silicon dioxide antiscaling dispersant, comprising the following components by mass percentage:

[0044] Polyamino polyether methylene phosphonic acid 30%

[0045] Amino acid methylene phosphonic acid 12%

[0046] Polymaleic anhydride 12%

[0047] Acrylic acid - hydroxypropyl acrylate copolymer 11%

[0048] A kind of preparation method of reverse osmosis feed water containing high TDS, high silicon dioxide antiscaling dispersant as above, comprises the following steps,

[0049] Step 1: Weighing polyamino polyether group methylene phosphonic acid, amino acid methylene phosphonic acid, polymaleic anhydride, acrylic acid-hydroxypropyl acrylate copolymer in sequence by mass percentage;

[0050] Step 2: Amino-terminated polyether and phosphorous acid are added to the reactor at a molar ratio of 1:4, and sulfuric acid with a mass fraction of phosphorous acid of 7% and partially demineralized water are added;

[0051]Step 3...

Embodiment 3

[0055] A reverse osmosis influent high TDS content, high silicon dioxide antiscaling dispersant, comprising the following components by mass percentage:

[0056] Polyamino polyether methylene phosphonic acid 25%

[0057] Amino acid methylene phosphonic acid 10%

[0058] Polymaleic anhydride 12%

[0059] Acrylic acid - hydroxypropyl acrylate copolymer 15%

[0060] A kind of preparation method of reverse osmosis feed water containing high TDS, high silicon dioxide antiscaling dispersant as above, comprises the following steps,

[0061] Step 1: Weighing polyamino polyether group methylene phosphonic acid, amino acid methylene phosphonic acid, polymaleic anhydride, acrylic acid-hydroxypropyl acrylate copolymer in sequence by mass percentage;

[0062] Step 2: Amino-terminated polyether and phosphorous acid are added to the reactor at a molar ratio of 1:4, and sulfuric acid with a mass fraction of phosphorous acid of 7% and partially demineralized water are added;

[0063] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com