Method for comprehensively recovering rare earth and iron from neodymium iron boron oil sludge

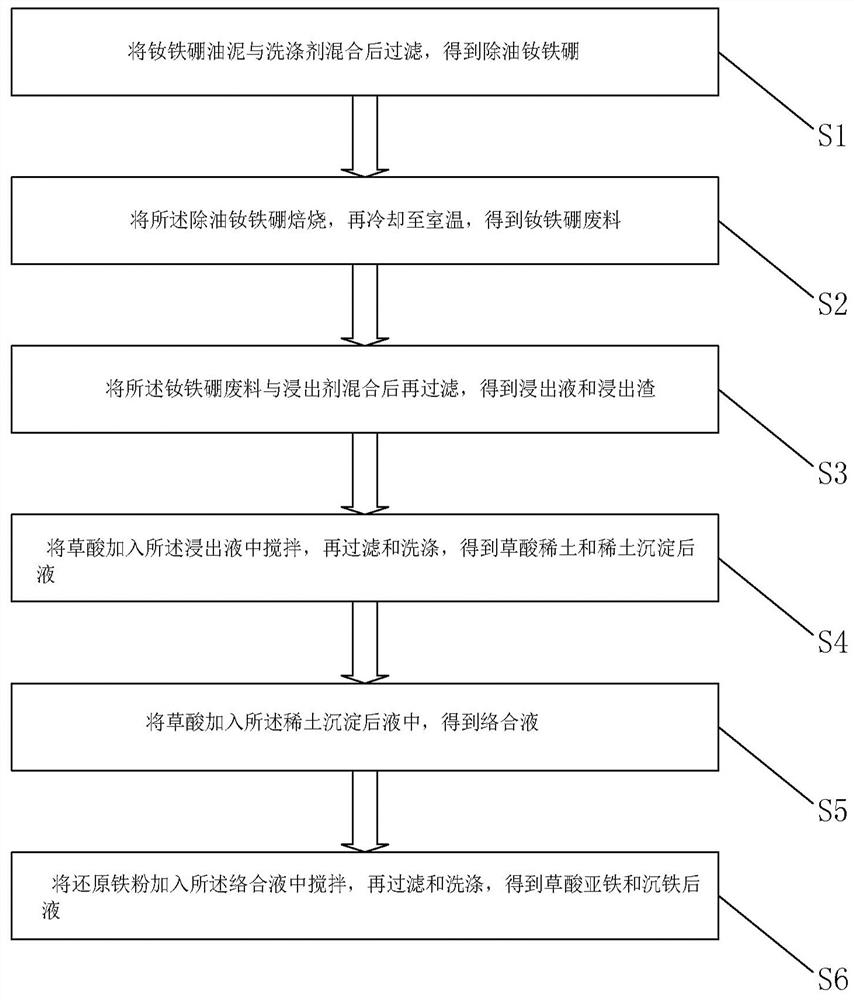

A NdFeB and sludge technology is applied in the field of comprehensive recovery of rare earth and iron from NdFeB sludge, which can solve the problems of polluting the environment and wasting iron resources, and achieves the effects of low oxidation roasting temperature and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

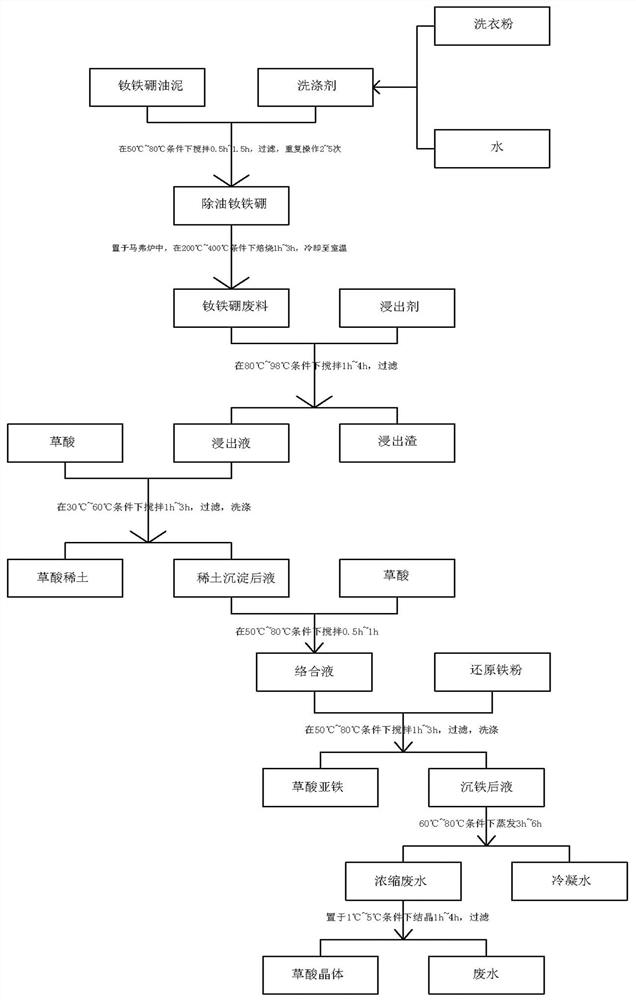

[0060] (1) Washing: According to the ratio of mass to volume of 1:4, stir and mix the washing powder and water to obtain detergent; according to the ratio of mass to volume of 1:4, mix NdFeB sludge with detergent, and mix it at 50 Stir at ℃ for 1.5h, filter, and repeat the operation 5 times to obtain degreased NdFeB;

[0061] (2) Roasting: put the degreased NdFeB in a muffle furnace, roast at 200°C for 2 hours, and cool to room temperature to obtain NdFeB waste;

[0062] (3) Co-leaching: According to the mass-to-volume ratio of 1:4, mix the NdFeB waste with the leaching agent, stir at 80°C for 2 hours, and filter to obtain the leaching solution and a very small amount of leaching residue; the leaching agent is hydrochloric acid, leaching The agent concentration is 4mol / L;

[0063] (4) Recovery of rare earths: According to the molar ratio of rare earth ions and oxalate radicals of 1:1, add oxalic acid into the leach solution, stir at 30°C for 2 hours, filter, and wash to obtai...

Embodiment 2

[0068] (1) Washing: According to the ratio of mass to volume of 1:8, stir and mix the washing powder and water to obtain detergent; according to the ratio of mass to volume of 1:3, mix NdFeB sludge with detergent, and mix it at 80 Stir at ℃ for 0.5h, filter, and repeat the operation 5 times to obtain degreased NdFeB;

[0069] (2) Roasting: put the degreased NdFeB in a muffle furnace, roast at 250°C for 1.5 h, and cool to room temperature to obtain NdFeB waste;

[0070] (3) Co-leaching: According to the mass-to-volume ratio of 1:5, mix the NdFeB waste with the leaching agent, stir at 98°C for 3 hours, and filter to obtain the leaching solution and a very small amount of leaching residue; the leaching agent is hydrochloric acid, leaching The agent concentration is 5mol / L;

[0071] (4) Recovery of rare earths: according to the molar ratio of rare earth ions to oxalate radicals of 1:4, add oxalic acid into the leach solution, stir at 60°C for 1.5h, filter, and wash to obtain rare...

Embodiment 3

[0076] (1) Washing: According to the ratio of mass to volume of 1:8, stir and mix the washing powder and water to obtain detergent; according to the ratio of mass to volume of 1:6, mix NdFeB sludge with detergent, and mix it at 80 Stir for 1.5h under the condition of ℃, filter, and repeat the operation 5 times to obtain degreased NdFeB;

[0077] (2) Roasting: put the degreased NdFeB in a muffle furnace, roast at 300°C for 3 hours, and cool to room temperature to obtain NdFeB waste;

[0078] (3) Co-leaching: According to the mass-to-volume ratio of 1:6, mix the NdFeB waste with the leaching agent, stir at 80°C for 4 hours, and filter to obtain the leaching solution and a very small amount of leaching residue; the leaching agent is hydrochloric acid, leaching The agent concentration is 6mol / L;

[0079] (4) Recovery of rare earths: According to the molar ratio of rare earth ions and oxalate radicals of 1:4, add oxalic acid into the leachate, stir at 30°C for 3 hours, filter, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com