Basalt/aramid fiber/mica paper and production method thereof

A basalt, mica paper technology, applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, plastic/resin/wax insulator, paper, etc., can solve the problem of reduced temperature resistance, poor temperature resistance, paper processing difficulties, etc. problems, to achieve the effect of improving quality, simple and convenient operation, and short production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

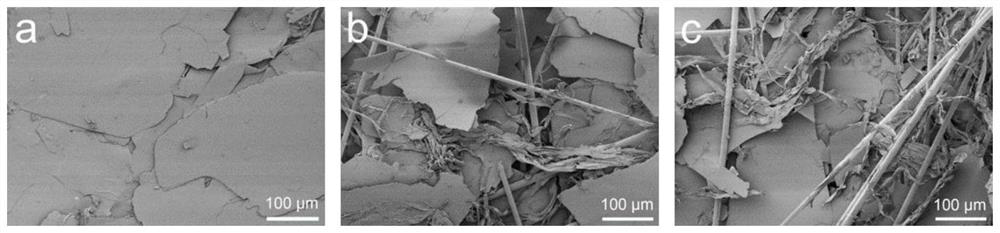

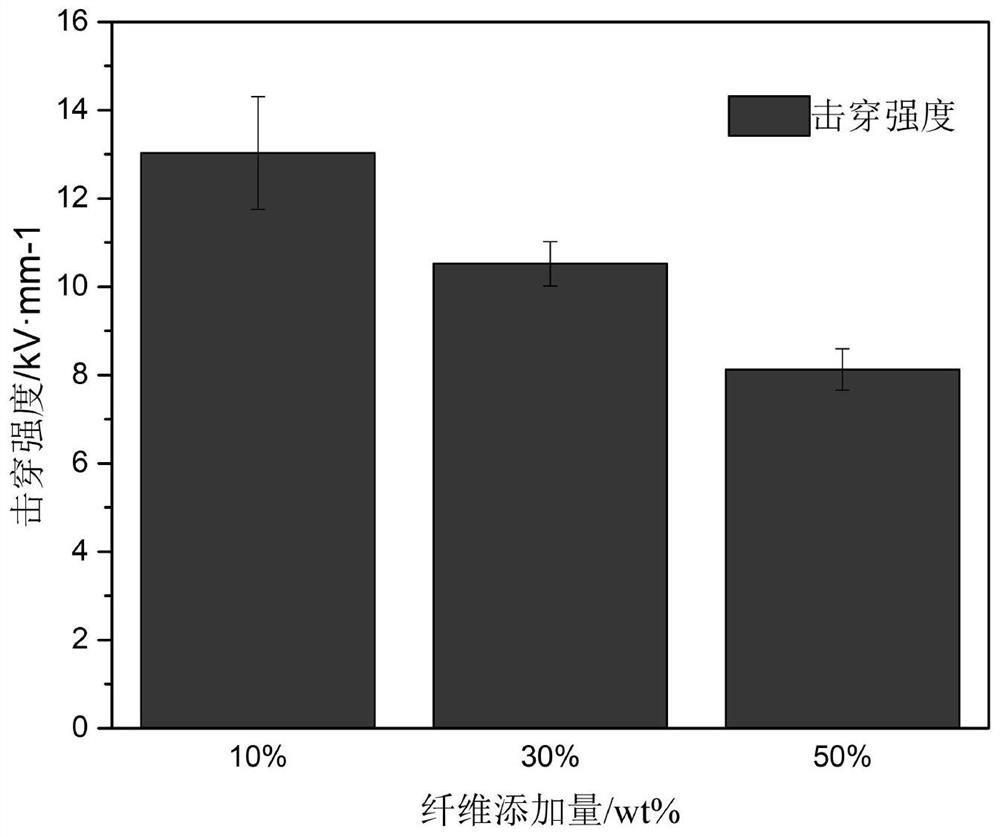

[0027] (1) Weigh 15,000 kg of basalt fibers with a diameter of 16 μm and a length of 0.5 mm, and 15,000 kg of aramid fibrids with a diameter of 40 μm and a length of 0.1 mm, and add them to 3,000,000 kg of water to stir and disperse to form a fiber suspension;

[0028] (2) Take muscovite scale 30000kg, join in the fiber suspension, obtain fiber / mica slurry;

[0029] (3) Use the rotary net mica paper machine to make paper, divide into five layers of rotary net pulp, dehydrate and dry to obtain basalt / aramid fiber / mica paper.

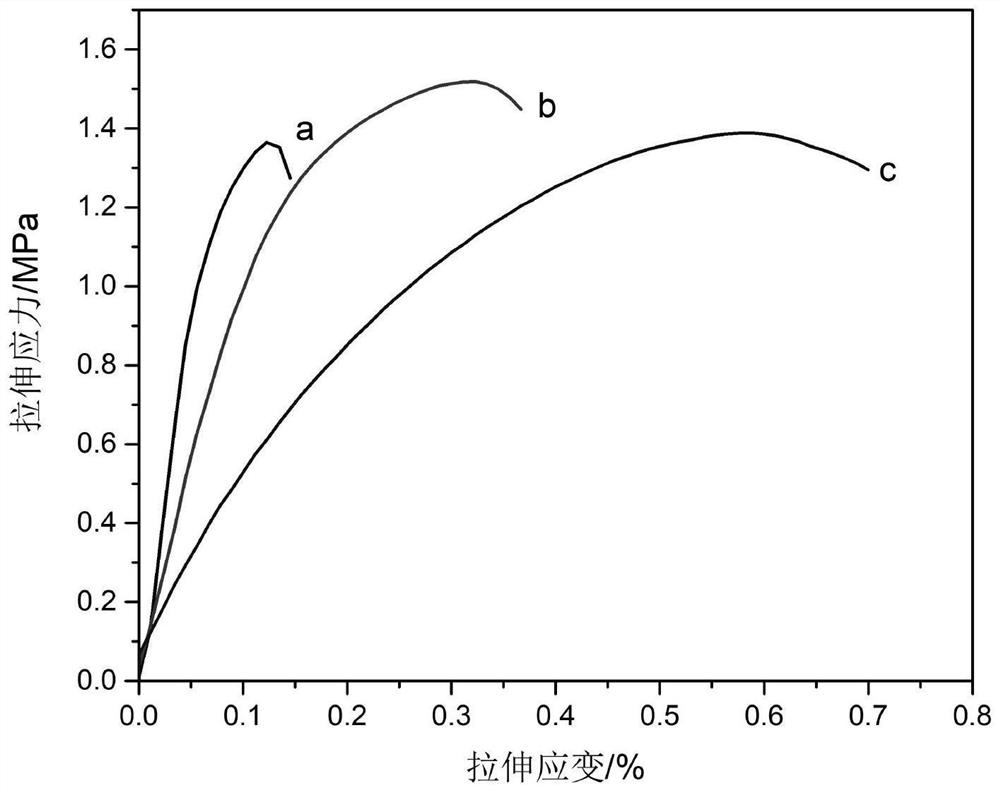

[0030] After testing, the air permeability of the mica paper prepared in this example is 1.9 μm / (Pa·s), the tensile stress is 1.5 MPa, and the thermal conductivity is 0.21 W / (m·k).

Embodiment 2

[0032] (1) Weigh 13,714 kg of basalt fibers with a diameter of 14 μm and a length of 0.7 mm, and 3,000 kg of aramid pulp fibers with a diameter of 30 μm and a length of 0.3 mm, and add them to 3,000,000 kg of water to stir and disperse to form a fiber suspension;

[0033] (2) Take by weighing phlogopite scale 39000kg, join in the fiber suspension, obtain fiber / mica pulp;

[0034] (3) Use a rotary net mica paper machine to make paper, divide into five round net sizings, dehydrate and dry to obtain basalt / aramid fiber / mica paper-based insulating materials.

[0035] After testing, the air permeability of the mica paper prepared in this embodiment is 16.875 μm / (Pa·s), the tensile stress is 0.441 MPa, and the thermal conductivity is 0.25 W / (m·k).

Embodiment 3

[0037] (1) Weigh 7500 kg of basalt fibers with a diameter of 12 μm and a length of 0.9 mm, and 7,500 kg of aramid fibrids with a diameter of 20 μm and a length of 0.6 mm, and add them to 3,000,000 kg of water to stir and disperse to form a fiber suspension;

[0038] (2) Weigh 45000kg of fluorophlogopite flakes and add them to the fiber suspension to obtain fiber / mica pulp;

[0039] (3) Use a rotary net mica paper machine for papermaking, divide into five layers of rotary net size, dehydrate and dry to obtain basalt / aramid fiber / mica paper-based insulating materials.

[0040] After testing, the air permeability of the mica paper prepared in this example is 1.7 μm / (Pa·s), the tensile stress is 1.5 MPa, and the thermal conductivity is 0.27 W / (m·k).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com