Lateral variable doping terminal structure and design method thereof

A terminal structure and design method technology, applied in CAD circuit design, electrical components, circuits, etc., can solve problems such as breakdown voltage reduction, charge sensitivity, and reliability impact of VLD terminals, so as to reduce impact and improve device withstand voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

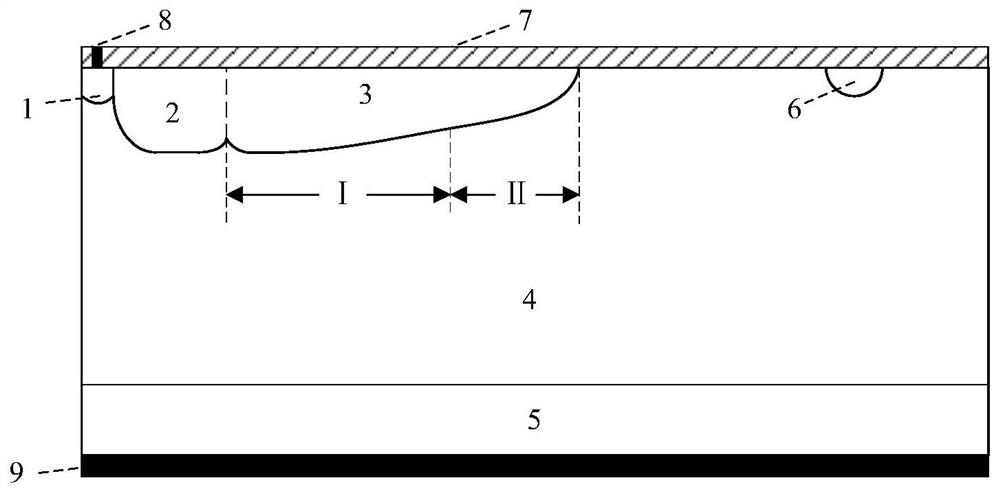

[0034] A laterally variable doping terminal structure, characterized in that it includes a passivation layer 7, a lightly doped first-type conductivity type drift region 4, and an anode region from the surface to the bottom, and the upper part of the interior includes a medium doping layer from left to right. The second conductivity type main junction region 1, the moderately doped second conductivity type transition region 2, the moderately doped second conductivity type segmented linear VLD termination region 3 and the heavily doped first conductivity type floating stop ring 6;

[0035] The anode region includes a heavily doped first conductivity type substrate 5 and an anode metal 9 below the heavily doped first conductivity type substrate 5, the heavily doped first conductivity type substrate 5 and the anode metal 9 form an ohmic contact, The anode metal 9 is connected to the external circuit; the main junction metal lead 8 is above the main junction region 1 of the medium-...

Embodiment 2

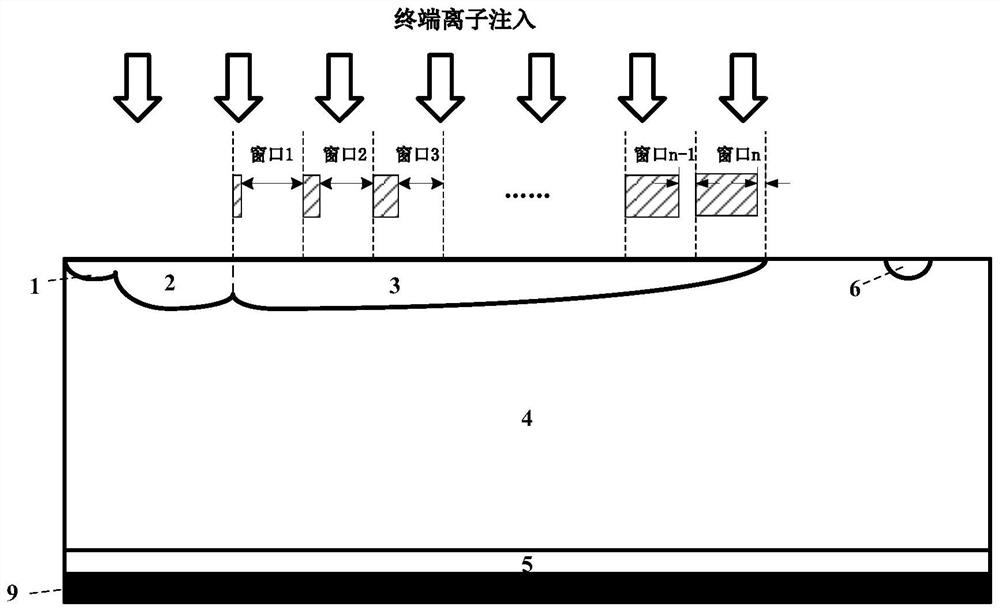

[0044] The difference between this embodiment and Embodiment 1 is that: the design method of the moderately doped second conductivity type piecewise linear VLD terminal region 3 is:

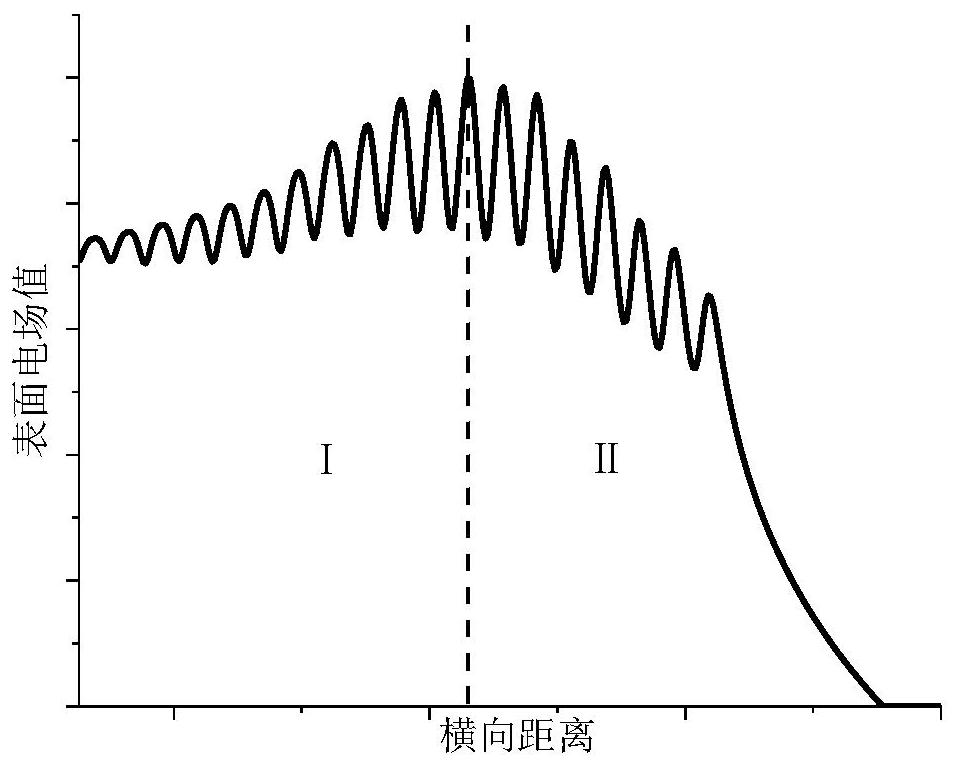

[0045] (1) First, the moderately doped second conductivity type piecewise linear VLD terminal region 3 is designed as a region where the impurity concentration decreases linearly from the main junction to the terminal end, and the surface electric field distribution is obtained through device simulation, and then the distance from the surface is selected. The implantation window closest to the electric field peak position is used as the turning point of the two-stage impurity concentration distribution region;

[0046] (2) The side near the main junction of the turning point is area I, and the side of the turning point close to the edge of the chip is area II, such as Figure 5 As shown, on the basis of the one-stage linear distribution, the window size at the turning point is controlled to be co...

Embodiment 3

[0048] This embodiment combines Embodiment 1 and Embodiment 2. The difference between this embodiment and Embodiment 1 is that the design method of the moderately doped second conductivity type segmented linear VLD terminal region 3 is as follows:

[0049] (1) First, the moderately doped second conductivity type piecewise linear VLD terminal region 3 is designed as a region where the impurity concentration decreases linearly from the main junction to the terminal end, and the surface electric field distribution is obtained through device simulation, and then the distance from the surface is selected. The implantation window closest to the electric field peak position is used as the turning point of the two-stage impurity concentration distribution region;

[0050] (2) The side near the main junction of the turning point is area I, and the side of the turning point close to the edge of the chip is area II, such as Image 6 As shown, on the basis of a one-stage linear distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com