Power type low-temperature lithium battery and preparation method thereof

A low-temperature lithium battery, power-type technology, applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problems of high frequency of concentrated outbreaks of safety accidents, shortened use time, and reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

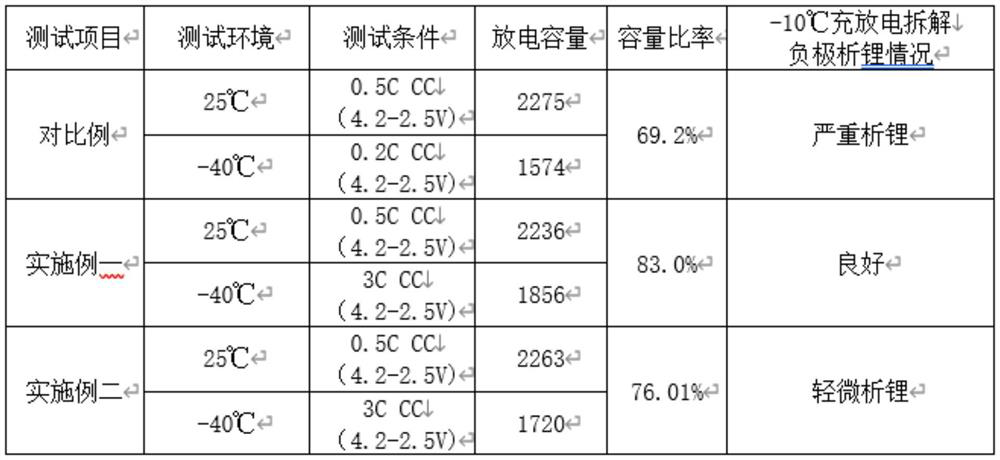

Examples

Embodiment 1

[0032] Preparation of positive electrode slurry and positive electrode sheet for lithium battery: use single-particle coated oxide large-particle lithium cobaltate as the positive electrode active material, and its weight content (relative to the weight of the powder, similar to the following) is 95.5%; Vinyl fluoride (PVDF molecular weight 1.3 million) is the binder, and its weight content is 1.0%; carbon nanotubes, conductive carbon black, and conductive graphite are used as conductive agents, and its weight content is 1.5%, 1.0%, and 1.0% respectively. The above materials are mixed by dry mixing at a stirring speed of 30HZ, dispersed at 200rpm, stirred for 2 hours, and the solvent methyl pyrrolidone (NMP) is added. Disperse and stir at 2000rpm for 5 hours to prepare positive electrode slurry, and lower the temperature to normal temperature to test the viscosity and fineness of the slurry. The positive electrode slurry is evenly coated on the aluminum foil of the positive el...

Embodiment 2

[0038] Preparation of positive electrode slurry and positive electrode sheet for lithium battery: use single-particle coated oxide large-particle lithium cobaltate as the positive electrode active material, and its weight content (relative to the weight of the powder, similar to the following) is 95.4%; Vinyl fluoride (PVDF molecular weight 1.3 million) is the binder, and its weight content is 1.0%; carbon nanotubes, conductive carbon black, and conductive graphite are used as conductive agents, and its weight content is 1.2%, 1.2%, and 1.2% respectively. The above materials are mixed by dry mixing at a stirring speed of 30HZ, dispersed at 200rpm, stirred for 2 hours, and the solvent methyl pyrrolidone (NMP) is added. Disperse and stir at 2000rpm for 5 hours to prepare positive electrode slurry, and lower the temperature to normal temperature to test the viscosity and fineness of the slurry. The positive electrode slurry is evenly coated on the aluminum foil of the positive el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com