Resin composition with UV shielding effect, and application of resin composition in copper-clad plate

A technology of resin composition and copper clad laminate, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of low optical detection efficiency and accuracy, tight resin supply, low peel strength and other problems , to improve the efficiency and accuracy of optical detection, increase the glass transition temperature, and achieve excellent anti-ghosting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

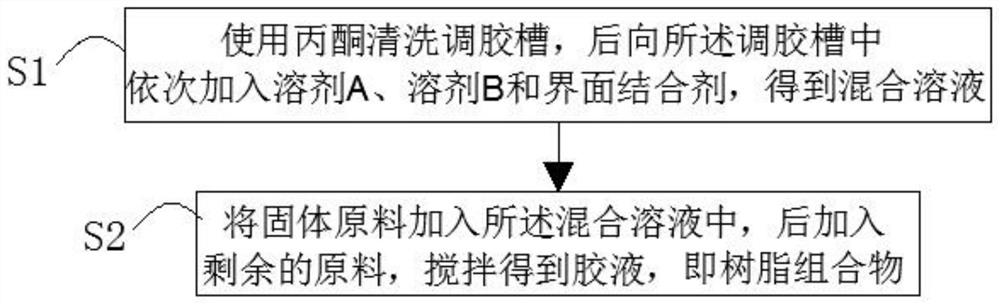

[0037] See figure 1 The present embodiment provides a method for preparing a resin composition having a UV shielding action for preparing a resin composition having a UV shielding action according to any one of claims 1 to 6. The preparation method includes the steps of:

[0038] S1 uses acetone cleaning tank, and then the solvent A, solvent B, and interface binding agent are sequentially added in the end of the tank to obtain a mixed solution.

[0039] S2 adds a solid feedstock into the mixed solution, then adding the remaining raw material, stirring to obtain a gum, i.e., a resin composition;

[0040] The solid feedstock was added to the mixed solution, and the solid feedstock was completely dissolved, and then the remaining raw material was added, stirred at 1000 rpm of rotational speed, and stirred at a rotational speed of 600 rpm to obtain a glue, SGS test on the gel, qualified The gum is a resin composition. Copper plate is obtained.

Embodiment 2

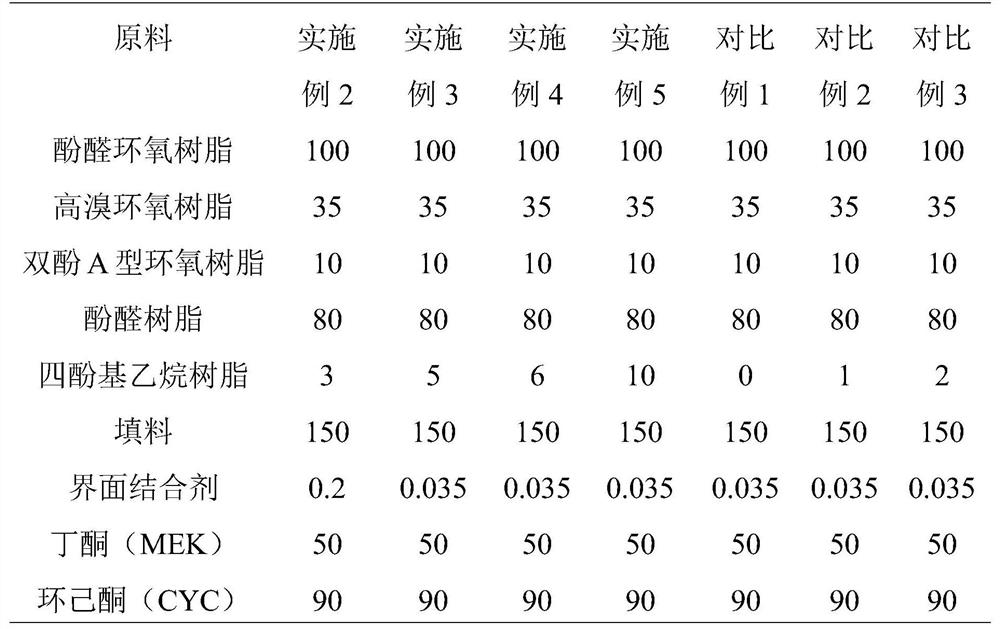

[0042] This embodiment provides a resin composition having a UV shielding action. The weight component of the resin composition is as follows: 100 parts of the phenolic epoxy resin, 35 parts of high bromide epoxy resin, 10 parts of the bisphenol A epoxy resin, 80 parts of the phenolic resin, 3 of tetophenolic ethane resin, filler 150 0.2 parts of the interface binding agent, 50 butanone, 90 cyclohexanone.

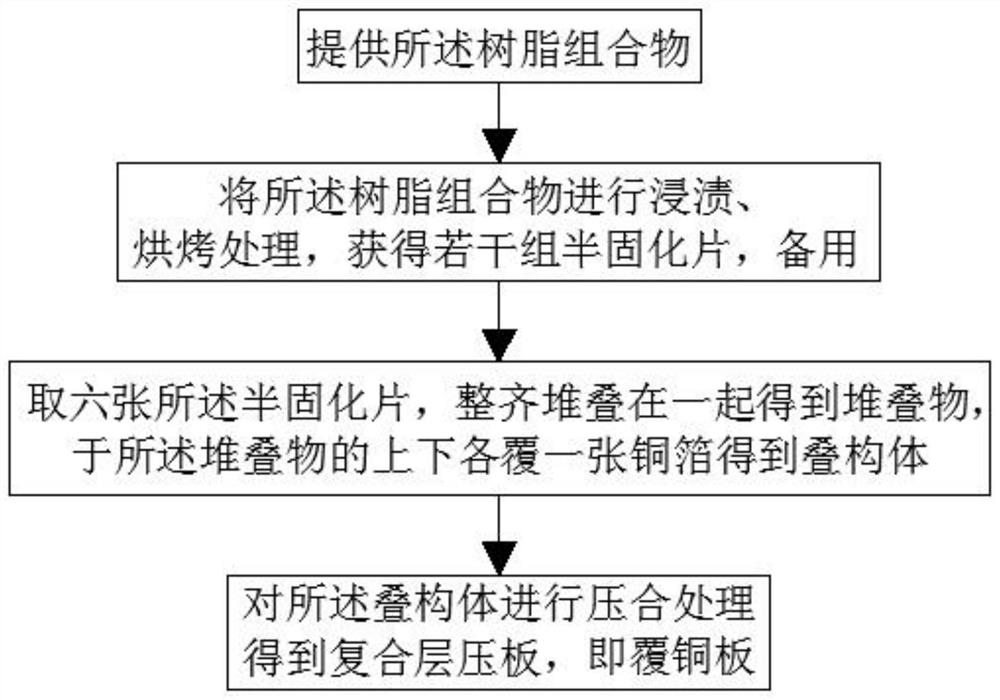

[0043] Please continue see figure 2 This embodiment also provides an application of a resin composition having a UV shielding action in a coated copper. The operation of the application is as follows:

[0044] The resin composition is provided which is prepared by the preparation method as described in Example 1.

[0045] The resin composition was impregnated, baked, and a semi-solid tablet, a spare sheet was obtained;

[0046] The resin composition was placed in a vertical plexamette for impregnation, and then baked to obtain a semi-solid tablet. During impregnation, during ba...

Embodiment 3

[0051] The difference between the present embodiment and the second embodiment is in the weight component of the resin composition: 5 parts of tetheld phenolic ethane resin, and 0.035 parts of the interface binding agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com