A pressure-sensitive material for monitoring the suspended area of a gob and its preparation method

A pressure-sensitive, goaf technology, applied in the field of mine safety, can solve problems such as high equipment cost and later maintenance costs, failure of the monitoring process, and easy damage, so as to avoid air leakage in the air, reduce input costs, and monitor the process Accurate and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

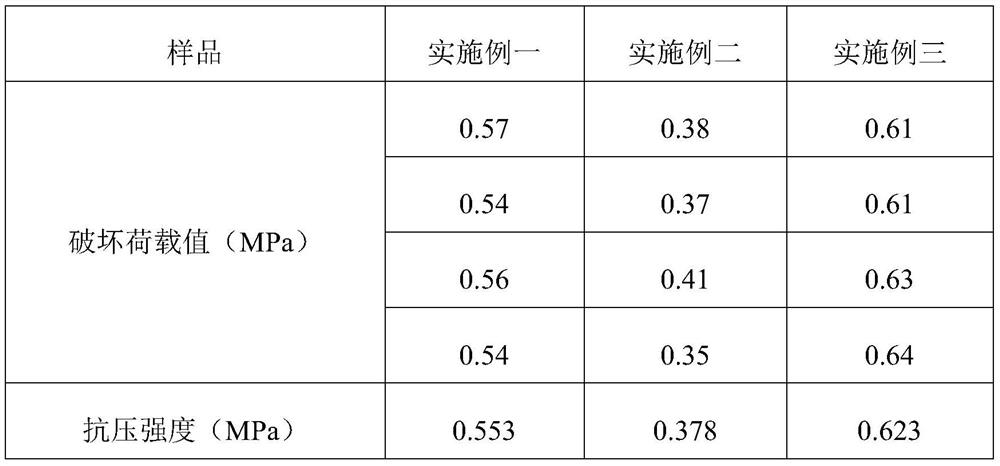

Embodiment 1

[0021] A pressure-sensitive material for monitoring the suspended area of a goaf, comprising a hollow spherical shell and a tracer material perfluoropentanone filled inside the shell; the hollow spherical shell is made of the following weight percentage Silicone resin compounded with silane material and curing agent: 8.3% trimethoxyphenylsilane, 13.9% methyltrichlorosilane, 33.3% methyltriethoxysilane, 44.5% curing agent; The hollow spherical shell ruptures under pressure to release the internal tracer material perfluoropentanone; the curing agent is a mixture of ethyl orthosilicate and silicon dioxide, and ethyl orthosilicate and dioxide The mass ratio of silicon is 1:7.

[0022] The above-mentioned preparation method of the pressure-sensitive material used for monitoring the suspended area of the goaf comprises the following steps:

[0023] S1. Weighing 11.25g of trimethoxyphenylsilane, 18.75g of methyltrichlorosilane and 45g of methyltriethoxysilane, the three silane m...

Embodiment 2

[0029] A pressure-sensitive material for monitoring the suspended area of a goaf, comprising a hollow spherical shell and a tracer material perfluorom-dimethylcyclohexane filled inside the shell; the hollow spherical shell is made of It is a silicone resin compounded by the following weight percentages of silane materials and curing agents: 5.6% of trimethoxyphenylsilane, 8.9% of methyltrichlorosilane, 41.1% of methyltriethoxysilane, 44.4% % curing agent; the hollow spherical shell ruptures under pressure and releases the internal tracer material perfluoromethylene dimethylcyclohexane; the curing agent is tetraethyl orthosilicate and silicon dioxide Mixture, the mass ratio of ethyl orthosilicate to silicon dioxide is 1:5.

[0030] The above-mentioned preparation method of the pressure-sensitive material used for monitoring the suspended area of the goaf comprises the following steps:

[0031] S1. Weighing 7.5g trimethoxyphenylsilane, 12g methyltrichlorosilane and 55.5g me...

Embodiment 3

[0037]A pressure-sensitive material for monitoring the suspended area of a goaf, comprising a hollow spherical shell and a tracer material perfluorodimethylcyclobutane filled inside the shell; the material of the hollow spherical shell is A silicone resin compounded by the following weight percentages of silane materials and curing agents: 4.4% trimethoxyphenylsilane, 11.1% methyltrichlorosilane, 40.0% methyltriethoxysilane, 44.5% A curing agent; the hollow spherical shell ruptures under pressure to release the internal tracer material perfluorodimethylcyclobutane; the curing agent is a mixture of tetraethyl orthosilicate and silicon dioxide, The mass ratio of ethyl orthosilicate to silicon dioxide is 1:9.

[0038] The above-mentioned preparation method of the pressure-sensitive material used for monitoring the suspended area of the goaf comprises the following steps:

[0039] S1, weighing 6g trimethoxyphenylsilane, 15g methyltrichlorosilane and 54g methyltriethoxysilane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com