Lead-based fast reactor magnesium oxide reflecting layer assembly and lead-bismuth fast spectrum reactor core arrangement

A core layout, magnesium oxide technology, applied in the direction of moderator/core structure, reactor fuel elements, reactors, etc., can solve the problems of limited improvement of neutron utilization rate, general neutron reflection ability, etc. Significant effect of sub-utilization, operating cycle, and significant improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

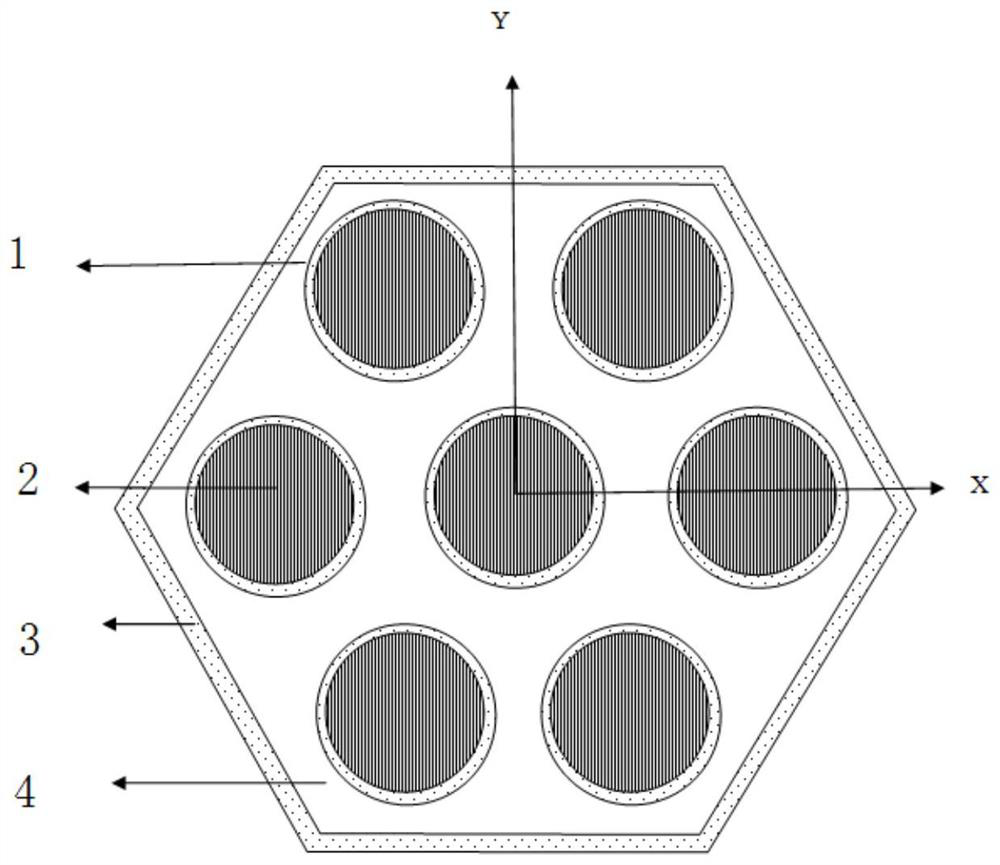

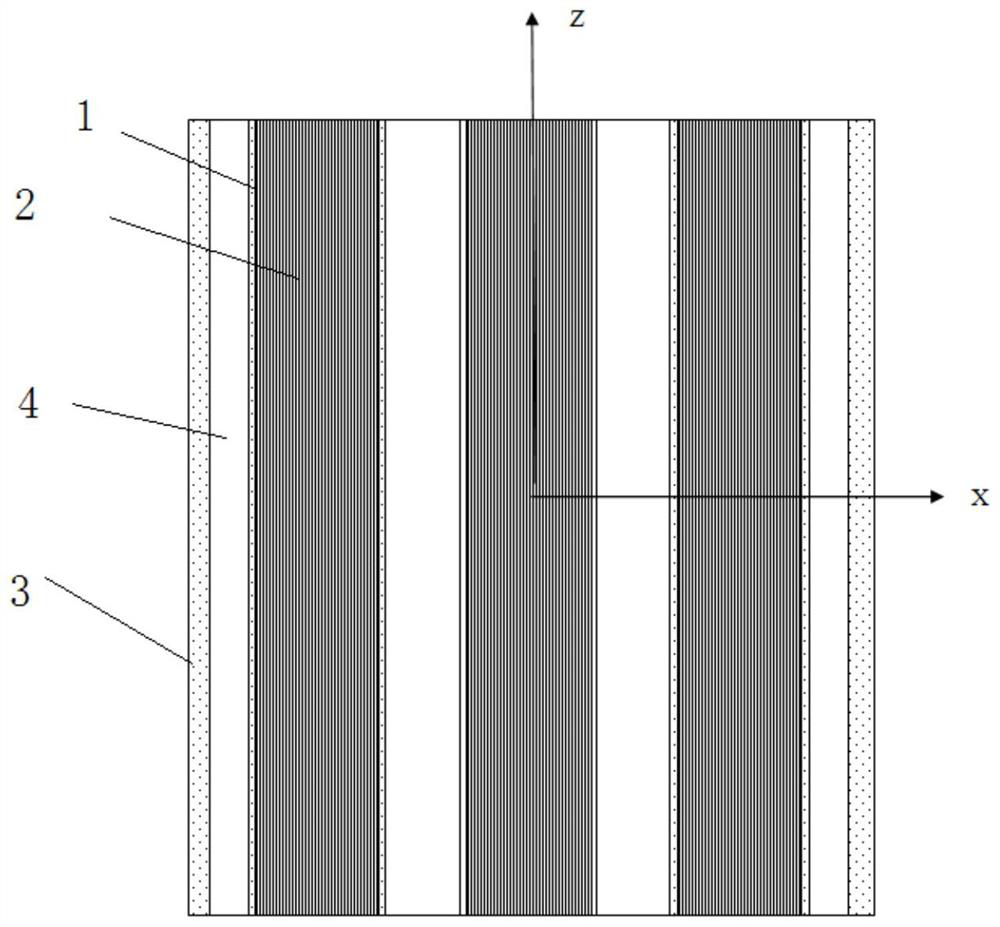

[0039] Such as figure 1 and figure 2 As shown in the 7-rod magnesium oxide reflective layer assembly, the assembly box 3 is a columnar structure with a hexagonal cross-section, that is, a hexagonal prism tubular structure, and a cylindrical enclosure 1 is placed inside the assembly box 3 along the axial direction, and the enclosure 1 Inside is magnesium oxide 2, and the gap between component box 3 and cladding 1 is all coolant 4;

[0040] The cladding 1 and the inner magnesium oxide 2 together form a reflector rod. The cladding 1 is cylindrical, so a cylindrical reflector channel is formed. In this embodiment, there are 7 reflector rods. According to the position of the center of the cross section, uniform distributed in a hexagonal cross-section. Among them, the cross-section center of the middle reflector rod coincides with the center of the hexagonal cross-section, and the remaining six reflector rods are evenly distributed around the outer circle of the central reflecto...

Embodiment 2

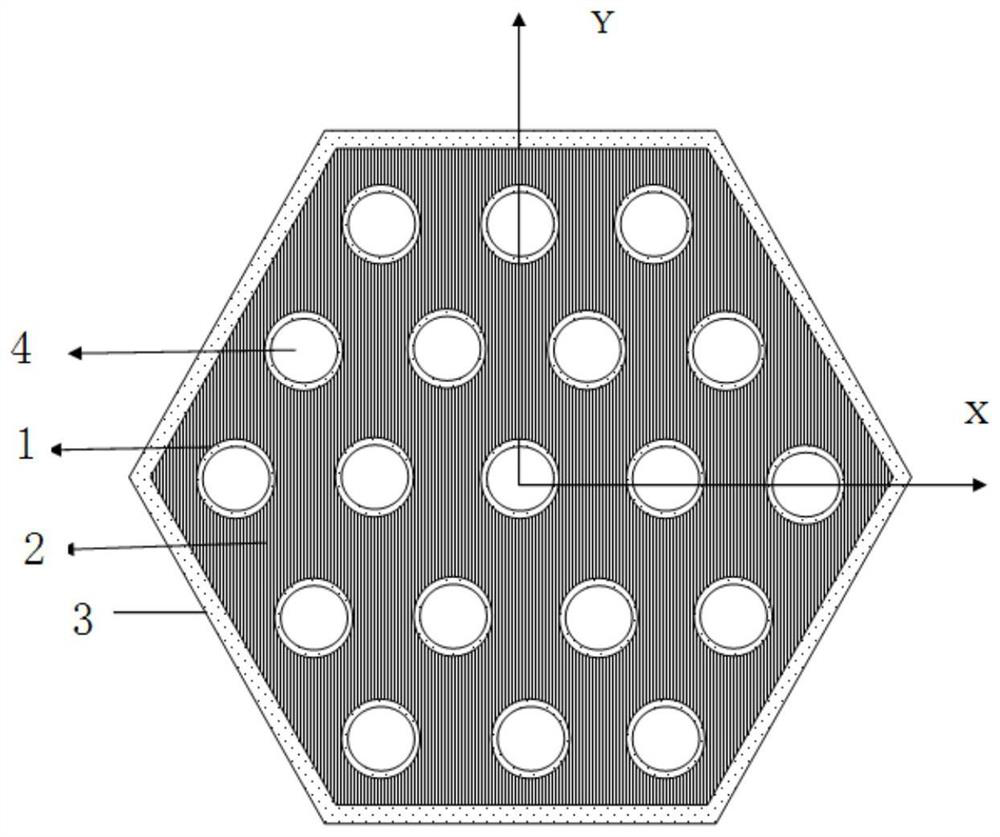

[0045] Different from Embodiment 1, the magnesium oxide 2 , the coolant 4 and the casing 1 have another arrangement in the component box 3 .

[0046] Such as image 3 and Figure 4 As shown, the component box 3 is also a columnar structure with a hexagonal cross-section, that is, a hexagonal prism tubular structure. The cylindrical casing 1 is placed inside the component box 3 along the axial direction, and the number of the casings 1 satisfies all the above three requirements. The distances between the centers of the cross-sections of two adjacent shells 1 are all equal, the center of the cross-section of the shell 1 at the center coincides with the center of the cross-section of the component box 3, and the number of shells 1 is 7, 19, 37, etc.

[0047] The difference is that the interior of the cladding 1 is a circulation channel for the coolant 4, and the gap between the cladding 1 and the component box 3 is magnesium oxide 2;

[0048] In this embodiment, the number of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com