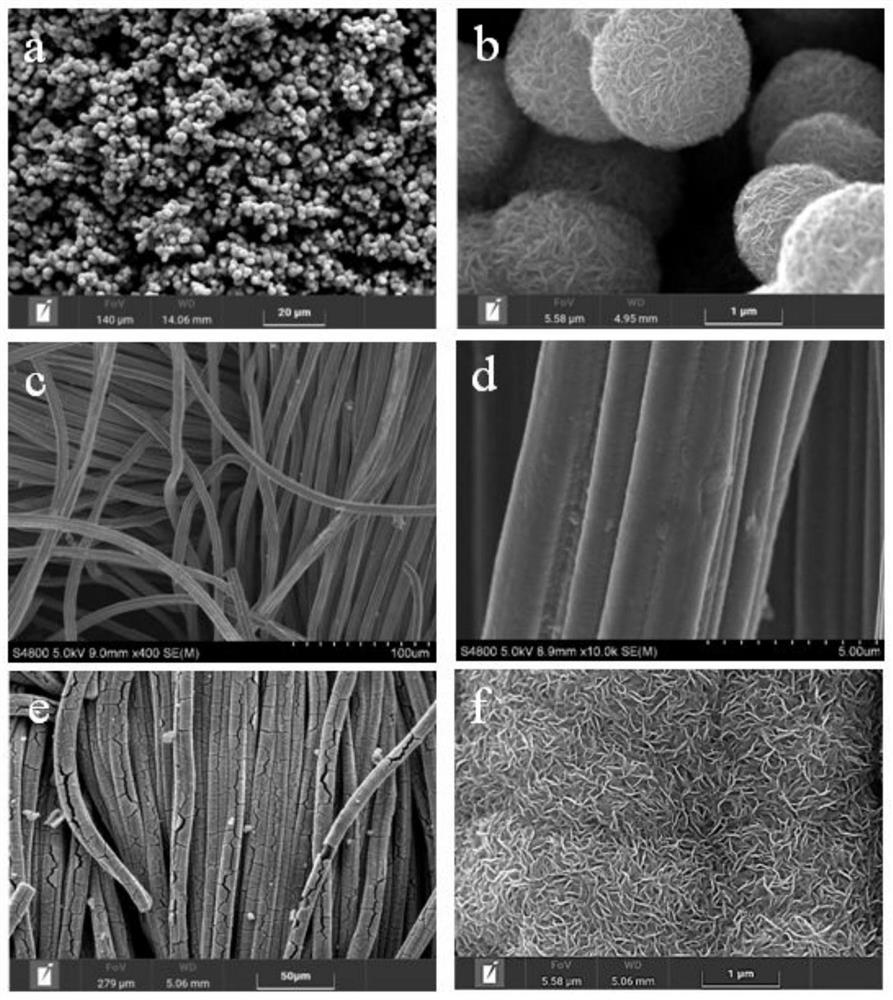

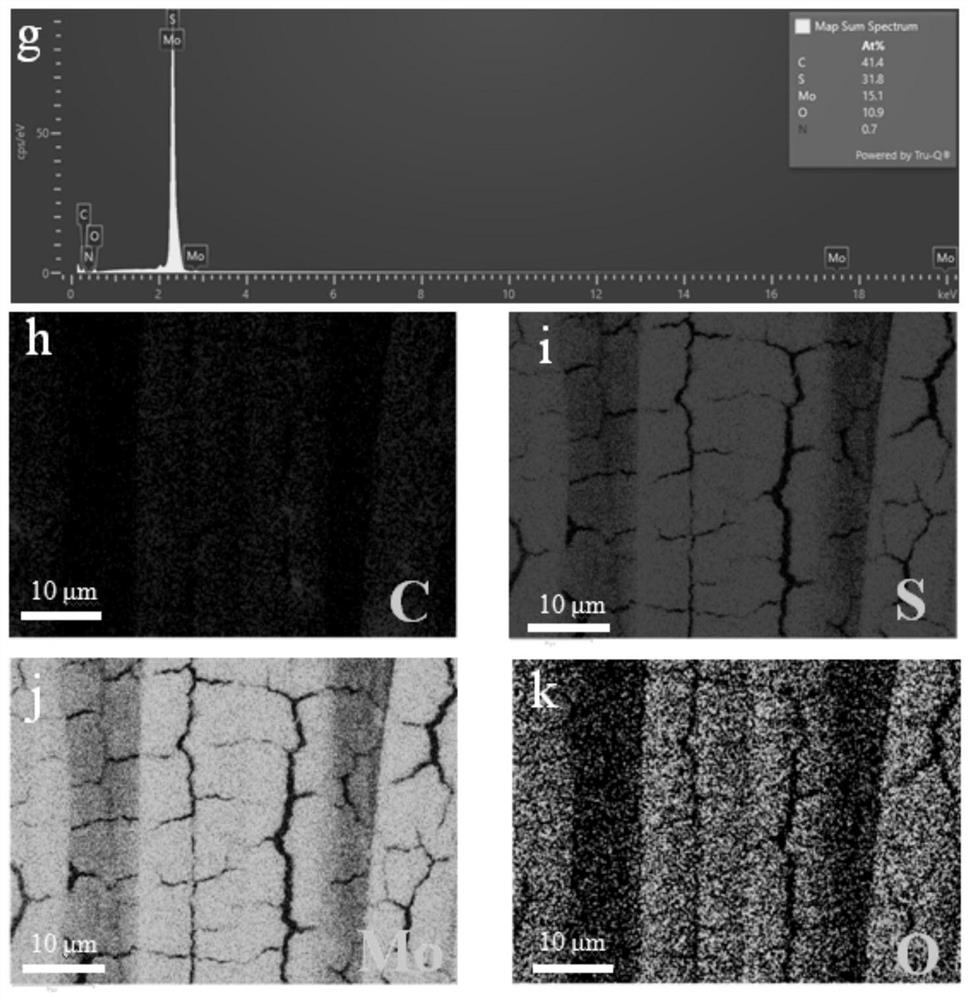

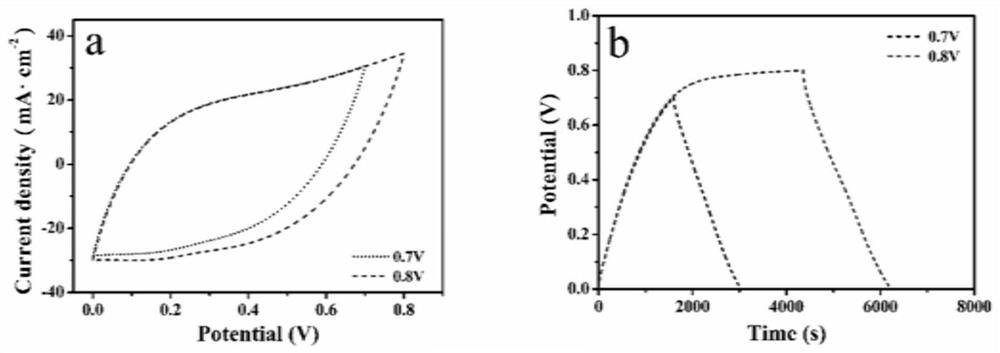

Flexible molybdenum disulfide/activated carbon cloth composite material, preparation method thereof, and application of composite material in flexible supercapacitor

A composite material and flexible technology, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of unsatisfactory electrode area capacitance, poor device rate performance, and weak binding force, etc., and achieves good flexibility and excellent performance. Lower cost than capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Activation of carbon cloth (CC): Treat the carbon cloth with mixed acid (concentrated sulfuric acid and concentrated nitric acid) oxidation method, first immerse the carbon cloth in concentrated H with a volume ratio of 2:1 2 SO 4 and concentrated HNO 3 solution mixture, add 3gKMnO 4 , reacted at 35°C for 3 hours, then added 100 mL of distilled water, and then added H to the mixture 2 o 2 solution until the solution is clear, and the activated carbon cloth (ACC) is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com