DDGS feed drying device and method

A drying device, DDGS technology, applied in drying, feed, dryer and other directions, can solve problems such as poor quality of feed products, save energy, reduce steam consumption, and improve feed drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

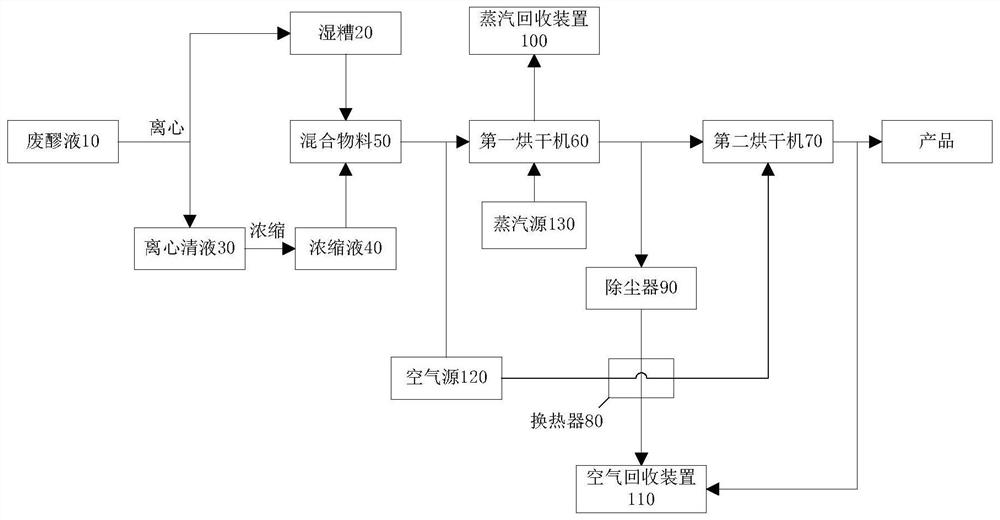

Embodiment 1

[0037] The 80°C waste mash 10 liquid from the alcohol factory is separated into wet grains 20 and centrifugal supernatant 30 through a centrifuge at 3000r / min. The water content in the wet grains 20 is 60%, and the water content in the centrifugal supernatant 30 is 4.5%. The centrifugal supernatant liquid 30 is concentrated by high temperature evaporation to become a concentrated liquid 40, the water content in the concentrated liquid 40 is 64%, the temperature of the mixed material 50 after mixing the wet grains 20 and the concentrated liquid 40 is 72°C, and the water content is 62%. The material 50 enters the shell side of the first dryer 60 at the same time, the temperature of the air entering the first dryer 60 is 25°C, the temperature of the air leaving the first dryer 60 is 93°C, and the steam enters the first dryer 60 The tube side, the steam temperature is 125°C, the pressure is 0.35MPa, the mixed material 50 is dried in the first dryer 60 until the moisture content is ...

Embodiment 2

[0039] The 85°C waste mash 10 liquid from the alcohol factory is separated into wet grains 20 and centrifugal supernatant 30 through a centrifuge at 3000r / min. The water content in the wet grains 20 is 65%, and the water content in the centrifugal supernatant 30 is 5.6%. The centrifugal supernatant liquid 30 is concentrated by high temperature evaporation to become a concentrated liquid 40, the water content in the concentrated liquid 40 is 67%, the temperature of the mixed material 50 after mixing the wet grains 20 and the concentrated liquid 40 is 75°C, and the water content is 66%. The material 50 enters the shell side of the first dryer 60 at the same time, the temperature of the air entering the first dryer 60 is 28°C, the temperature of the air leaving the first dryer 60 is 98°C, and the steam enters the first dryer 60 tube side, the steam temperature is 130°C, the pressure is 0.45MPa, the mixed material 50 is dried in the first dryer 60 until the moisture content is 18%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com