Low-carbon emission type VOCs purification device and method adopting low-temperature plasma technology

A low-temperature plasma and purification device technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., to achieve the effects of strong adaptability to working conditions, reduced footprint, and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

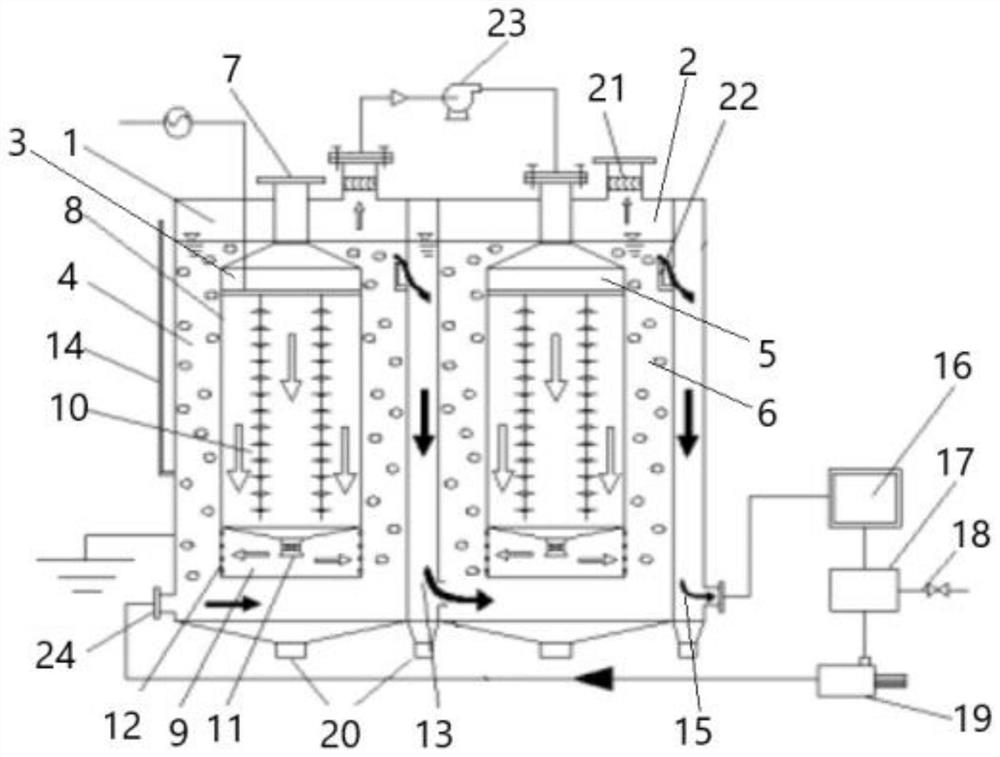

[0028] Such as figure 1 Shown is a schematic diagram of the device structure of the present invention, a low-carbon emission type VOCs purification device of low-temperature plasma technology, including: gas-liquid phase purification unit one 1, gas-liquid phase purification unit two 2, the gas-liquid phase purification unit two The gas outlet of phase purification unit one 1 is connected with the inlet port of said gas-liquid phase purification unit two 2; said gas-liquid phase purification unit one 1 includes: gas phase VOCs purification chamber one 3 and liquid phase carbon capture Chamber one 4, the gas phase VOCs purification chamber one 3 is placed inside the liquid phase carbon capture chamber one 4; the gas-liquid phase purification unit two 2 includes: gas phase VOCs purification chamber two 5 and liquid phase carbon capture Collection chamber two 6, the gas-phase VOCs purification chamber two 5 is placed inside the liquid-phase carbon collection chamber two 6, the li...

Embodiment 2

[0037] This embodiment provides a low-carbon emission type VOCs purification method of low-temperature plasma technology. VOCs waste gas enters the gas-phase VOCs purification chamber-3 of the gas-liquid phase purification unit-1 through the air inlet 7, and the low-temperature The high-energy electrons generated by the plasma discharge react with the active groups and are transformed into small molecular inorganic substances such as carbon dioxide and water, as well as a small amount of by-products. The purified tail gas enters in the form of microbubbles after gas phase equalization and micropore diffusion. In the liquid-phase carbon capture chamber-4, the carbon dioxide in the tail gas is absorbed by the absorption solution, and the remaining tail gas is collected at the top outlet of the gas-liquid phase purification unit-1, and the gas is intercepted by the demister 21 After carrying the droplets, the booster air pump 23 sends them into the gas-liquid phase purification un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com