Drying device and drying method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

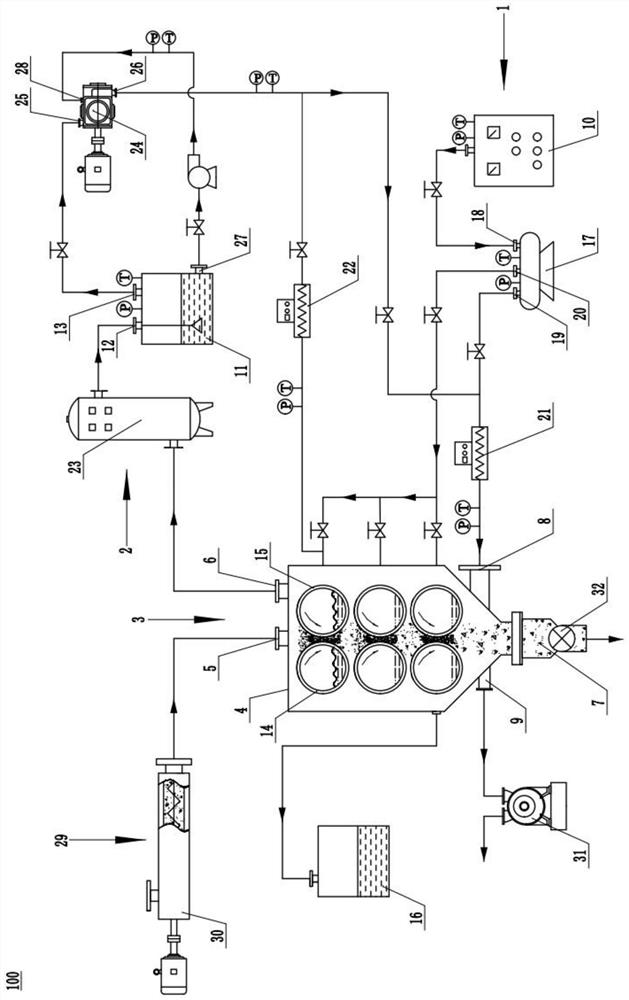

[0046] Such as figure 1 As shown: this embodiment provides a drying device 100, the material to be dried is wet sludge, including a drying system 1 and a steam recovery system 2, the drying system 1 includes a dryer 3 and a steam generator 10, and the dryer 3 includes The drying chamber 4 and the drier arranged inside the drying chamber 4, the drying machine 3 adopts a vertical layout, the top of the drying chamber 4 is provided with a feed inlet 5 and an exhaust gas outlet 6, and the bottom of the drying chamber 4 is provided with a discharge port 7, The steam convection drying inlet 8 and the air outlet 9, the steam convection drying inlet 8 and the drier are all communicated with the steam generator 10, and the steam recovery system 2 includes a separation buffer tank 11, which is used to separate water and steam , the tail gas outlet 6 communicates with the inlet 12 of the separation buffer tank 11, and the gas outlet 13 of the separation buffer tank 11 communicates with t...

Embodiment 2

[0064] This embodiment provides a drying method using the drying device 100 of Embodiment 1, comprising the following steps:

[0065] Step 1, open the control valve between the steam generator 10 and the air sub-cylinder 17, start the steam generator 10, and open between the sub-air cylinder 17 and the first thermal compensator 21, between the sub-air cylinder 17 and each group of rollers after generating steam The control valve in between starts the first thermal compensator 21, heats the convective drying steam, and passes the steam into the dryer 3, so that the dryer 3 is preheated, and the air in the dryer 3 is exhausted;

[0066] Step 2, start the delivery pump 30, and the sludge enters the dryer 3 through the feed port 5 at the top of the drying chamber 4;

[0067] Step 3: The sludge is dried from top to bottom by heat conduction through counter rolls with saturated steam, and at the same time, the sludge is thermally convectively dried from bottom to top by the convecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com