Interlayer material as well as preparation method and application thereof

A technology of interlayer materials and substrate materials, applied in electrical components, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of unfavorable battery electrochemical performance and slow conversion, and achieve superior electrocatalytic activity, strong adsorption, and good cycle performance and the effect of rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

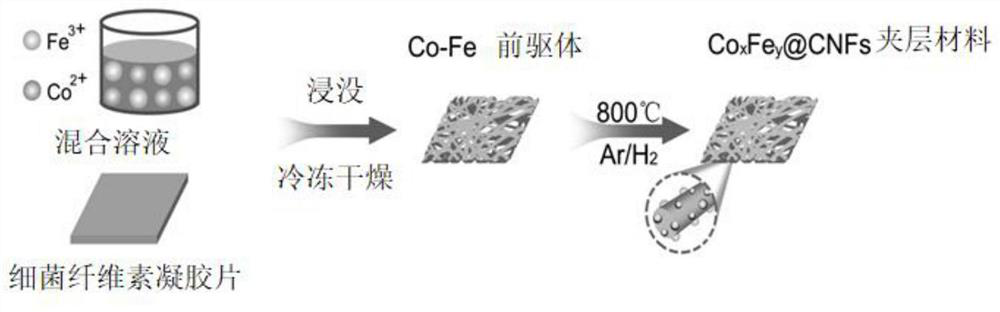

[0062] This embodiment provides a kind of preparation method of interlayer material, and described preparation method specifically comprises the following steps:

[0063] (1) Prepare 2mmol / L mixed metal salt solution, dissolve a certain quality of cobalt chloride hexahydrate and ferric chloride hexahydrate in 400mL deionized water, stir at room temperature until the solution is clear, and obtain an orange-yellow solution;

[0064] (2) Cut the commercial bacterial cellulose gel sheet with a thickness of 3mm into a size of 8*12cm, and soak it in the above-mentioned mixed solution for 2h, and a magnetic stirring of 600r / min is required in the process;

[0065] (3) The gel sheet soaked in the metal salt solution obtained in step (2) is clamped up and down with smooth glass sheets of the same size, and the two ends are fixed with the same pressure, and the thickness of the gel sheet after soaking is controlled by an appropriate pressure. At about 3mm, use filter paper to absorb exc...

Embodiment 2

[0071] This embodiment provides a kind of preparation method of interlayer material, and described preparation method specifically comprises the following steps:

[0072] (1) Prepare a 3mmol / L mixed metal salt solution, dissolve a certain quality of cobalt chloride hexahydrate and ferric chloride hexahydrate in 400mL deionized water, stir at room temperature until the solution is clear, and obtain an orange-yellow solution;

[0073] (2) Cut the commercial bacterial cellulose gel sheet with a thickness of 3mm into 8*12cm size, and soak it in the above-mentioned mixed solution for 1h, and a magnetic stirring of 500r / min is required in the process;

[0074] (3) The gel sheet soaked in the metal salt solution obtained in step (2) is clamped up and down with smooth glass sheets of the same size, and the two ends are fixed with the same pressure, and the thickness of the gel sheet after soaking is controlled by an appropriate pressure. At about 3mm, use filter paper to absorb excess...

Embodiment 3

[0080] This embodiment provides a kind of preparation method of interlayer material, and described preparation method specifically comprises the following steps:

[0081] (1) Prepare a mixed metal salt solution of 4 mmol / L, dissolve a certain quality of cobalt chloride hexahydrate and ferric chloride hexahydrate in 400 mL of deionized water, stir at room temperature until the solution is clear, and obtain an orange-yellow solution;

[0082] (2) Cut the commercial bacterial cellulose gel sheet with a thickness of 3mm into a size of 8*12cm, and soak it in the above-mentioned mixed solution for 1.5h, and a magnetic stirring of 550r / min is required in the process;

[0083] (3) The gel sheet soaked in the metal salt solution obtained in step (2) is clamped up and down with smooth glass sheets of the same size, and the two ends are fixed with the same pressure, and the thickness of the gel sheet after soaking is controlled by an appropriate pressure. At about 3mm, use filter paper t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com