A nico@nis embedded s-doped carbon nanotube composite material and its preparation and application

A technology of composite materials and carbon nanotubes, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the limitations of large-scale application of reversible air electrode catalysts, the high cost of noble metal catalysts, and the inability to mass Production and general use, etc., to achieve excellent dual-functional catalytic activity, low cost, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A NiCo@NiS inlaid S-doped carbon nanotube composite material proposed by the present invention and its preparation and application will be further described in detail below with reference to the accompanying drawings and specific examples. The advantages and features of the present invention will become apparent from the following description and claims.

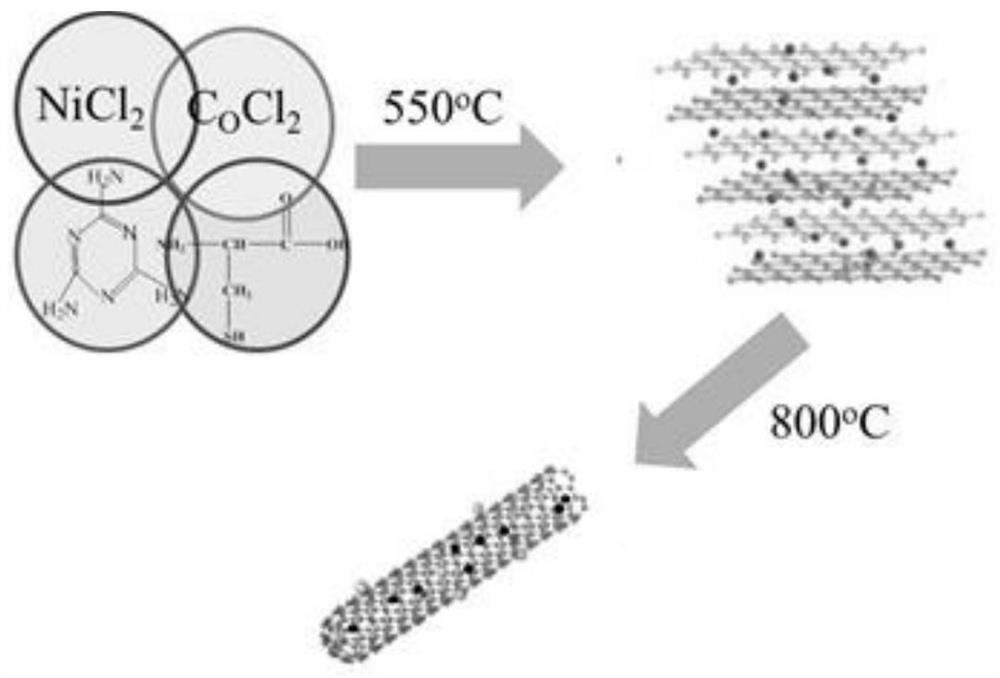

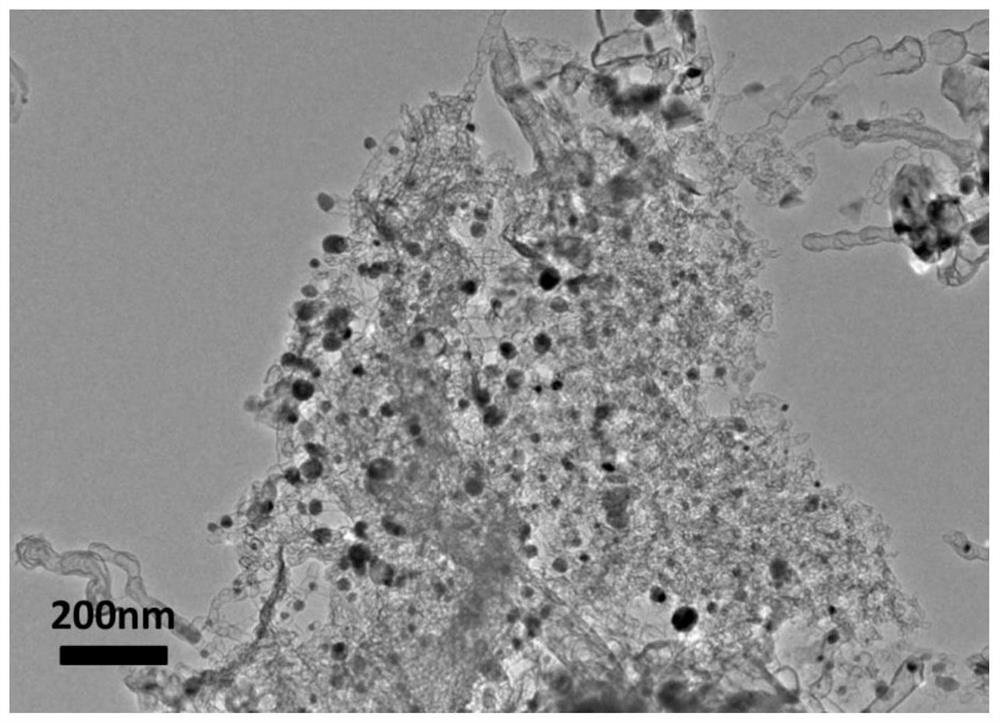

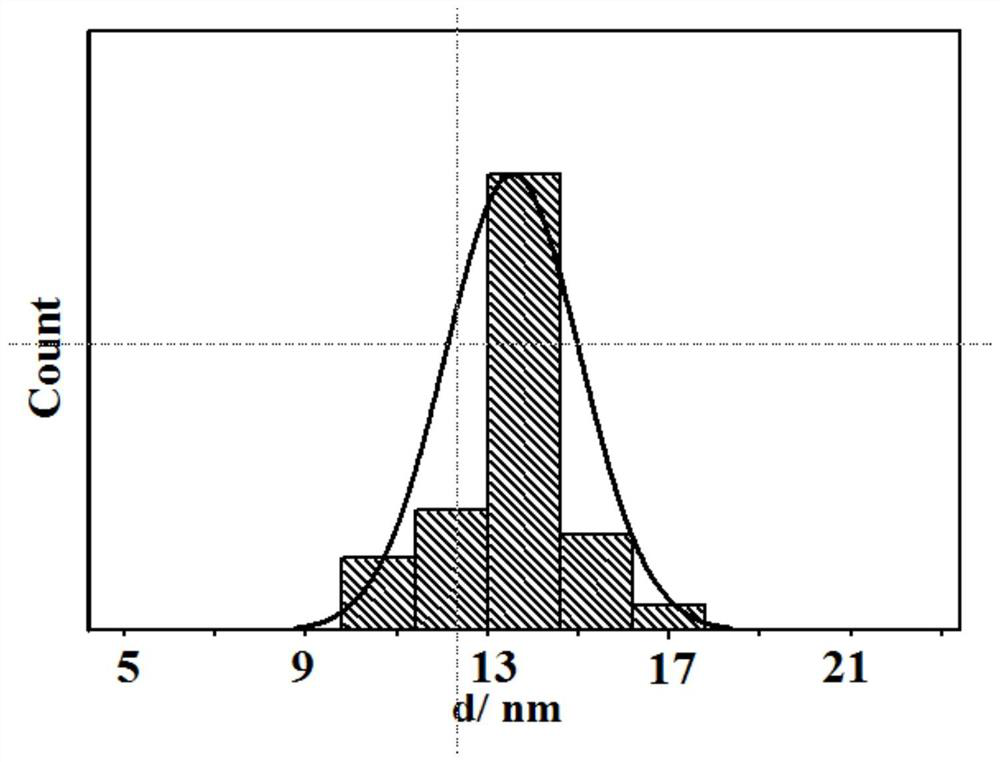

[0037] In this embodiment, refer to figure 1 , a NiCo@NiS-inlaid S-doped carbon nanotube composite was prepared as follows:

[0038] (1) the melamine of 20mmol, the cysteine of 1mmol, the nickel chloride hexahydrate of 0.5mmol and the cobalt chloride hexahydrate of 0.5mmol are mixed, then grind to obtain solid powder;

[0039] (2) calcination in the first stage: the solid powder obtained in step (1) is placed in a muffle furnace, raised to 550° C. with a heating rate of 3° C. / min, and kept for 2 hours;

[0040] (3) calcination in the third stage: the temperature was then raised to 800°C at a heating rate of 5°C / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com