V-doped cuprous selenide nanosheet assembled nanotube array structure material, preparation method and application thereof

A nanotube array, cuprous selenide technology, applied in electrolytic components, electrodes, electrolytic organic production, etc., can solve problems such as poor selectivity and stability, limitations, etc., achieve low cost, improve electrical conductivity, and accelerate catalytic kinetics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

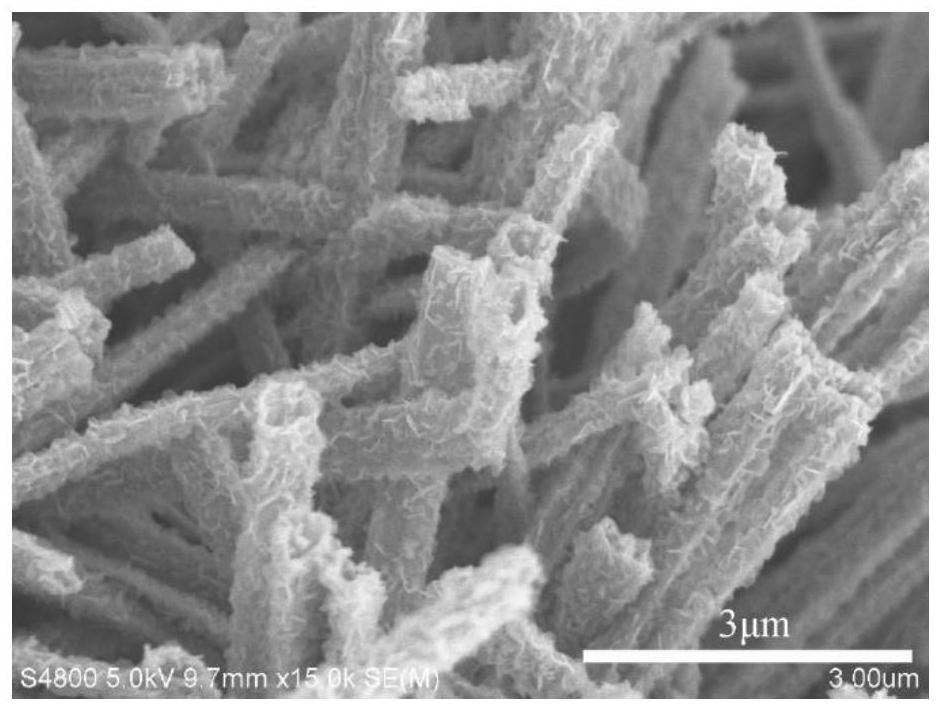

[0076] A preparation method of a nanotube array structure material assembled by V-doped cuprous selenide nanosheets, comprising the following steps:

[0077] The copper foam (CF) with an area of 2.5×3.5cm was soaked in 6M hydrochloric acid for 15min, and then washed 3 times with deionized water and absolute ethanol. Accurately measure 30mL of deionized water in a clean small beaker, and accurately weigh 3.8mmol of ammonium persulfate ((NH 4 ) 2 S 2 o 8 ), 75mmol sodium hydroxide (NaOH) was added to the above-mentioned small beaker, magnetically stirred to form a mixed solution, the pre-treated foamed copper was dipped into the mixed solution, and reacted for 20min at room temperature, and then the foamed copper covered by the blue sample was used Wash with deionized water and absolute ethanol three times each, and dry in an oven at 70°C for 12 hours. Accurately measure 30mL of deionized water in a clean small beaker, and accurately weigh 1.5mmol of sodium borohydride (Na...

Embodiment 2

[0086] A preparation method of a nanotube array structure material assembled by V-doped cuprous selenide nanosheets, comprising the following steps:

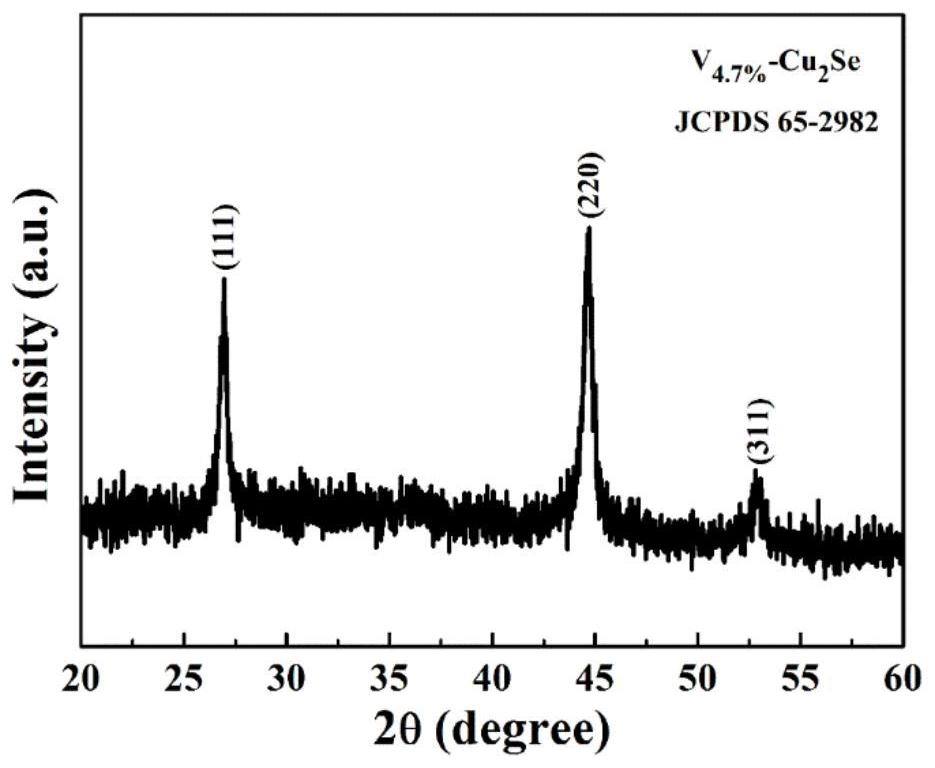

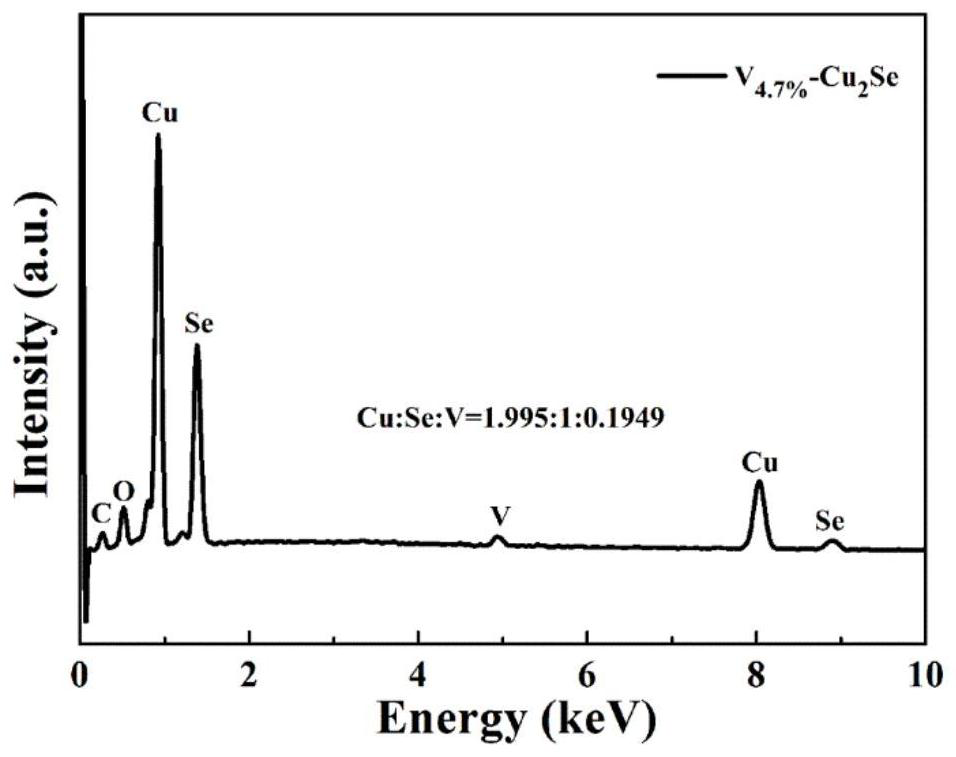

[0087] Accurately weigh 1.5mmol sodium borohydride (NaBH 4 ), 0.3mmol Se powder, 0.15mol sodium hydroxide (NaOH) and 0.03 mmol or 0.09 mmol ammonium metavanadate (NH 4 VO 3 ), added into a small beaker with 30 mL of deionized water and stirred ultrasonically to form a reddish-brown mixed solution. Then it was transferred to a 50mL polytetrafluoroethylene-lined stainless steel reactor, and the copper foam covered with the blue precursor in Example 1 was placed obliquely into the stainless steel reactor, and reacted in an oven at 120°C for 6h. After the reaction was finished, it was naturally cooled to room temperature, and the copper foam covered by the black sample was washed three times with deionized water and absolute ethanol, and the obtained sample was dried in a vacuum oven at 70°C for 12 hours to obtain V-doped Cu 2 Na...

Embodiment 3

[0092] A V-doped Cu 2 Nanotube array structure material assembled by Se nanosheets as electrocatalytic carbon dioxide reduction reaction (CO 2 ER) catalyst application.

[0093] The specific application method is: V-doped Cu with an area of 0.5×0.5cm 2 The nanotube array structure material assembled by Se nanosheets was used as the working electrode, and the carbon rod and the Ag / AgCl electrode were used as the counter electrode and the reference electrode respectively in 0.1M KHCO 3 In the H-type electrolytic cell of the electrolyte solution, the CHI760E electrochemical workstation was used for testing.

[0094] The present invention prepares Cu with foam copper 2 Nanotube array structure assembled by Se nanosheets and V-doped Cu 2 The nanotube array structure assembled by Se nanosheets was used as the working electrode and assembled in an H-type electrolytic cell to measure their CO 2 ER performance for comparison. Cu prepared on foamed copper 2The preparation of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com