Catalyst with double-alloy composite micro-mesoporous structure as well as preparation method and application of catalyst

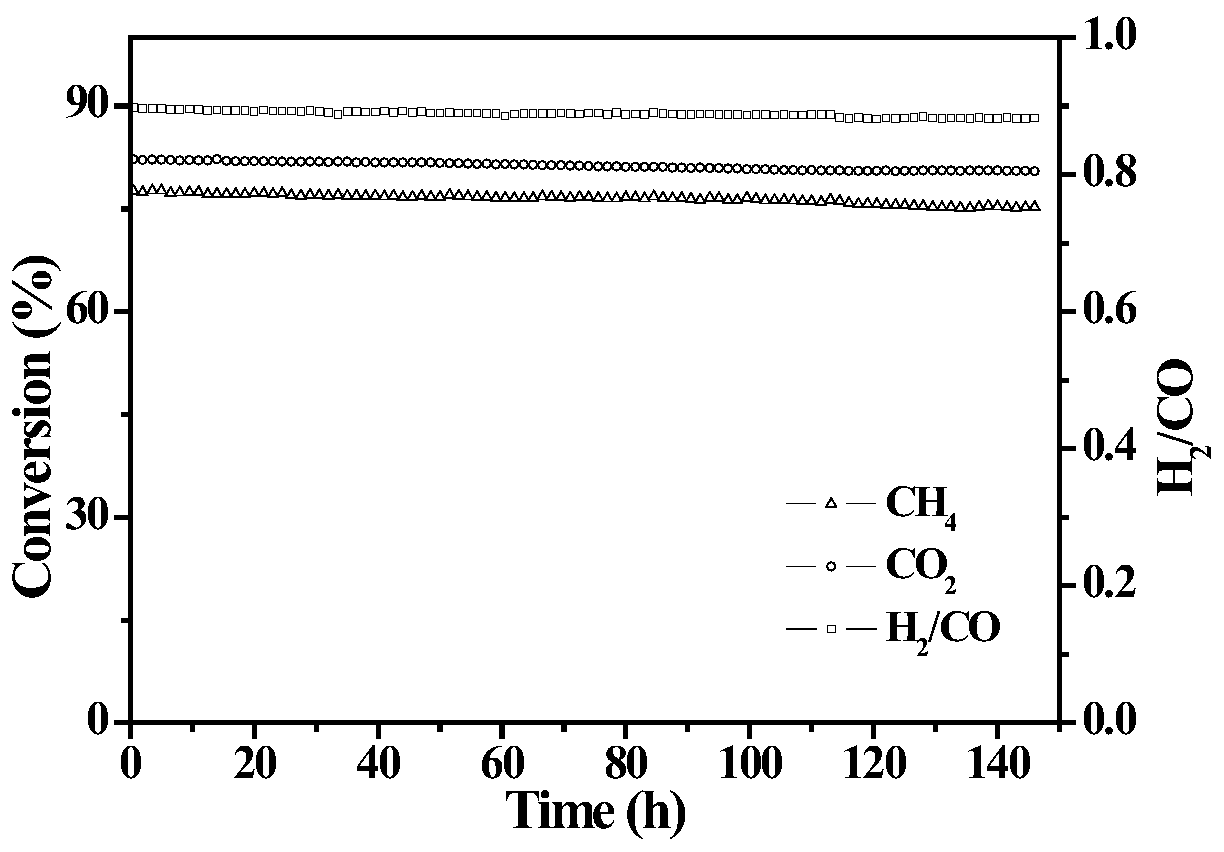

A catalyst and dual-alloy technology, applied in the field of preparation of catalysts with dual-alloy composite micro-mesoporous structure, can solve the problems of high catalyst deactivation speed, high price, sintering loss of active components, etc., and improve the anti-coking performance. And anti-sintering ability, improve activity and stability, reduce the effect of carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

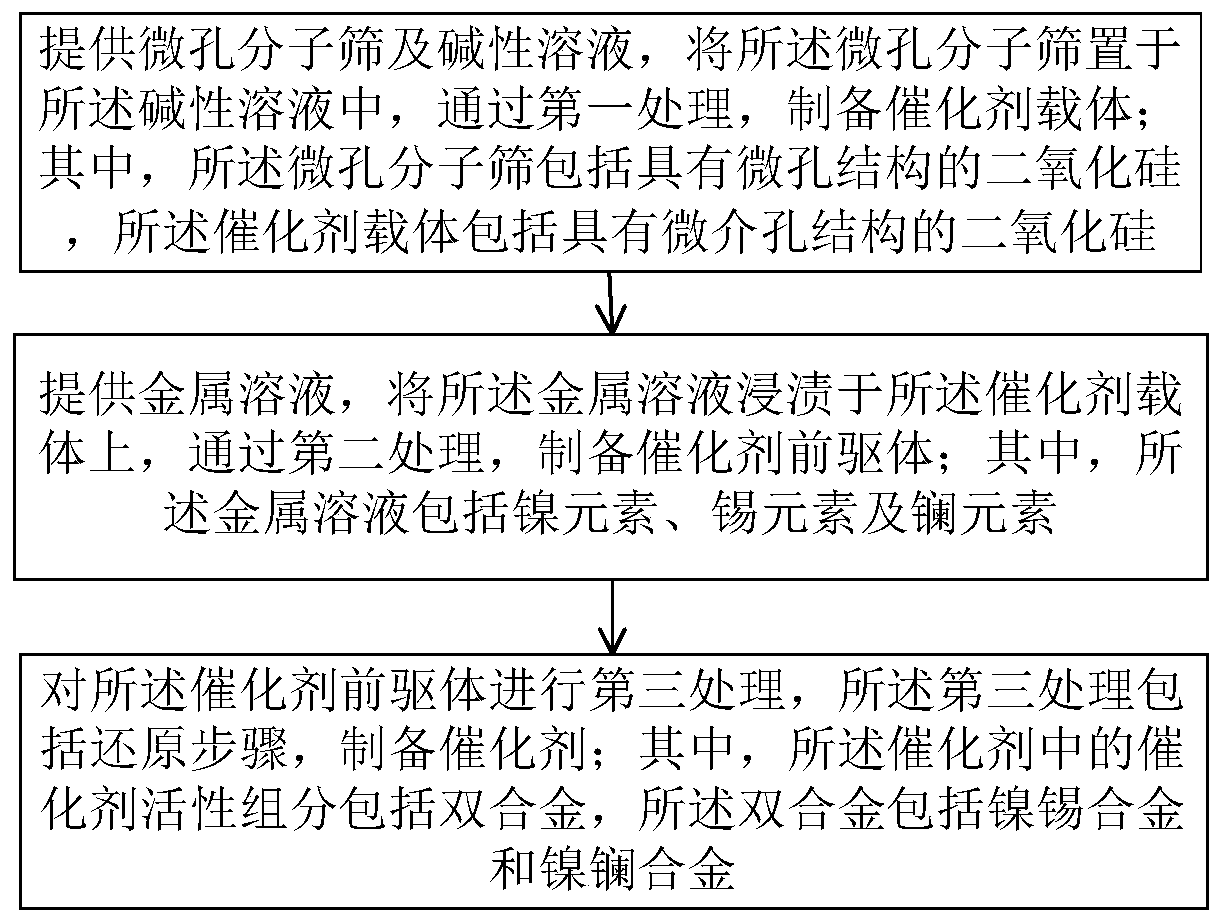

[0048] The preparation of a catalyst with a double-alloy composite micro-mesoporous structure comprises the following steps:

[0049] Weigh 2.5g of urea and dissolve it in 50mL of deionized water to form an alkaline solution, put 5g of microporous molecular sieve ZSM-5 in the alkaline solution, then seal the above mixture in a 100mL hydrothermal kettle, and place in 150°C water Heat treatment for 48 hours, wash the product in the hydrothermal kettle with deionized water until neutral, then oven-dry it at 110°C for 2 hours, then place it in a muffle furnace, raise the temperature to 550°C at 2°C / min, and bake at 550°C for 3 hours, A catalyst support is prepared, the catalyst support comprising silica having a micro-mesoporous structure.

[0050] Weigh 0.331g of nickel chloride, 0.376g of lanthanum nitrate, and 0.132g of tin tetrachloride, dissolve them in 5mL of deionized water to form a metal solution, impregnate the metal solution on 3g of the prepared catalyst carrier, and c...

Embodiment 2

[0055] The preparation of a catalyst with a double-alloy composite micro-mesoporous structure comprises the following steps:

[0056] Weigh 1.5g potassium carbonate and dissolve it in 50mL deionized water to form an alkaline solution, put 5g microporous molecular sieve ZSM-5 in the alkaline solution, then seal the above mixture in a 100mL hydrothermal kettle, and heat at 140°C Hydrothermal treatment for 24 hours, wash the product in the hydrothermal kettle with deionized water until neutral, then oven-dry at 110°C for 2 hours, then place it in a muffle furnace, raise the temperature to 550°C at 2°C / min, and roast at 550°C for 3 hours , to prepare a catalyst carrier, the catalyst carrier includes silicon dioxide with a micro-mesoporous structure.

[0057] Weigh 0.28g nickel nitrate, 0.376g lanthanum nitrate, 0.066g tin tetrachloride, dissolve in 5mL deionized water to form a metal solution, impregnate the metal solution on 3g of the prepared catalyst carrier, and continue to st...

Embodiment 3

[0062] The preparation of a catalyst with a double-alloy composite micro-mesoporous structure comprises the following steps:

[0063] Weigh 1.5g potassium carbonate and dissolve it in 50mL deionized water to form an alkaline solution, put 5g microporous molecular sieve ZSM-5 in the alkaline solution, then seal the above mixture in a 100mL hydrothermal kettle, and heat at 140°C After hydrothermal treatment for 24 hours, wash the product in the hydrothermal kettle with deionized water to neutrality, then oven-dry it at 110°C for 2 hours, then place it in a muffle furnace, raise the temperature to 550°C at 2°C / min, and roast at 550°C for 3 hours. A catalyst support is prepared, the catalyst support comprising silica having a micro-mesoporous structure.

[0064] Weigh 0.37g nickel nitrate, 0.188g lanthanum nitrate, 0.066g tin tetrachloride, dissolve in 5mL deionized water to form a metal solution, impregnate the metal solution on 3g of the prepared catalyst carrier, and continue t...

PUM

| Property | Measurement | Unit |

|---|---|---|

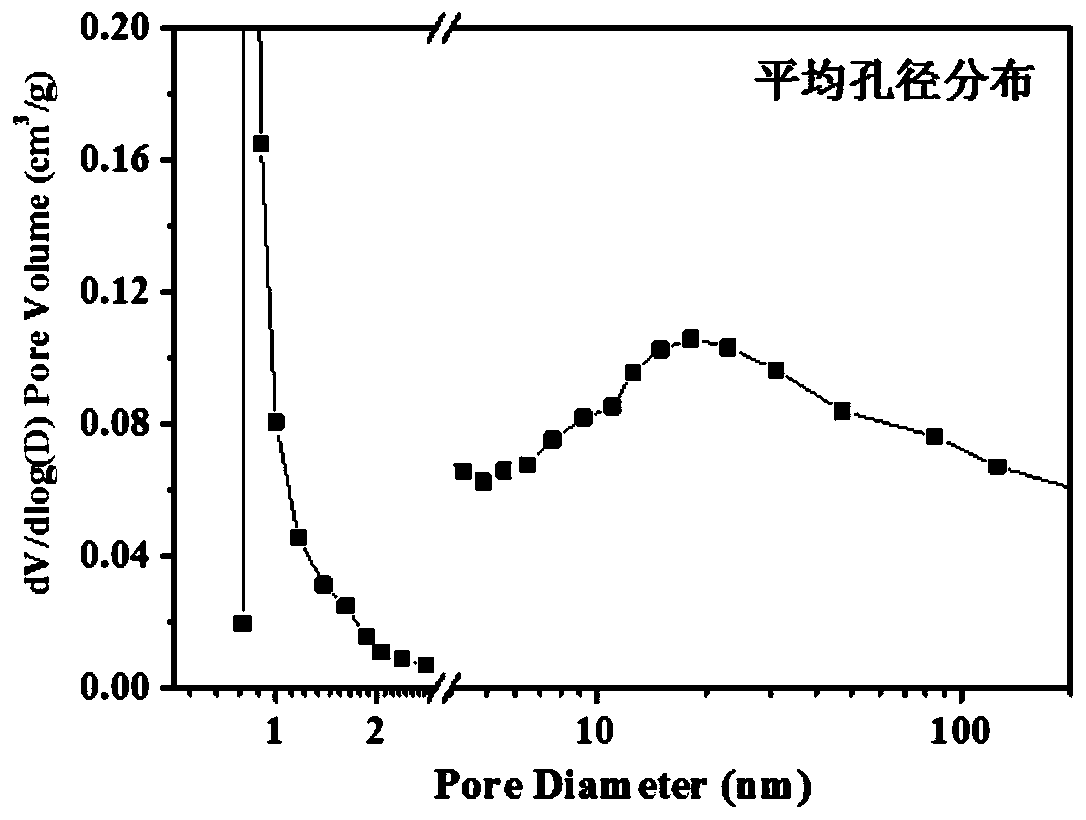

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com