Titanium-zirconium adsorbent as well as preparation method and application thereof

An adsorbent, titanium-zirconium technology, applied in the field of new-type titanium-zirconium adsorbent and its preparation, can solve the problems of complex process and long reaction cycle of titanium-zirconium adsorbent, achieve the effect of reducing reaction time, simple process and increasing ethanol concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing a novel titanium-zirconium adsorbent with simple procedures. The titanium-zirconium adsorbent is synthesized by an integral continuous loading method, and the specific steps are:

[0053] S1 First prepare the zirconium-titanium ion solution: add 250ml ethanol and 15ml hydrochloric acid to a 500ml beaker, put the beaker in an ice water bath, add 20ml TiCl while stirring constantly 4 Solution, stir until no smoke is produced and the solution turns pale yellow, then stop;

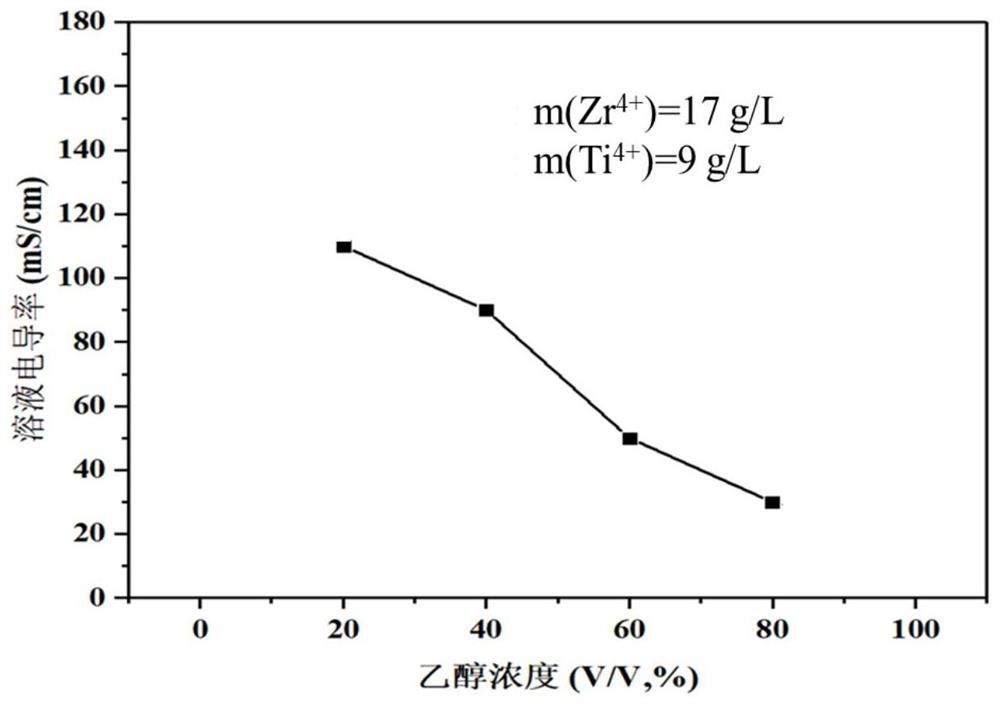

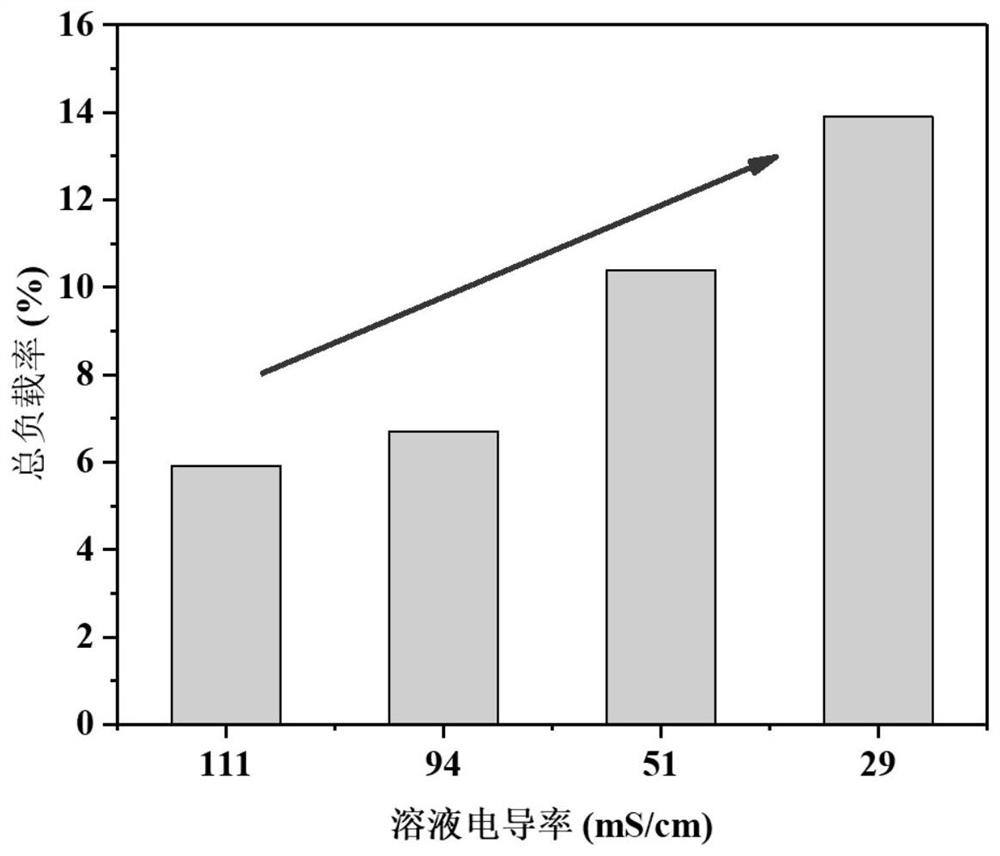

[0054] S2 then added 60g ZrOCl 2 ·8H 2 O (the molar ratio of titanium to zirconium is 1:1), add 20mL of deionized water, and continue to stir until completely dissolved. At this time, the concentration of titanium ions in the solution was 9g / L, the concentration of zirconium ions was 17g / L, the concentration of hydrochloric acid was 4.9%, the concentration of ethanol was 82.0%, and the conductivity of the measured solution was 29mS / cm.

Embodiment 2

[0056] The steps of this comparative example are basically the same as those in Example 1, keeping the concentration of titanium ions in the solution at 9 g / L, the concentration of zirconium ions at 17 g / L, the concentration of hydrochloric acid at 4.9%, and the molar ratio of titanium to zirconium at 1:1. The difference is: in step S1, ethanol, hydrochloric acid, TiCl 4 The addition amount of solution is respectively: 250ml ethanol, 21ml hydrochloric acid, 27ml TiCl 4 Solution; ZrOCl in step S2 2 ·8H 2 The addition amount of O is 82.6g, and deionized water is 122ml.

[0057] The concentration of ethanol was 59.5%, and the measured conductivity of the solution was 51 mS / cm.

Embodiment 3

[0066] The present embodiment is the method for the novel titanium-zirconium adsorbent prepared by the titanium-zirconium ion solution in Example 1, Example 2 and comparative examples A and B, comprising the following steps:

[0067] S3 Weigh 20g of strongly basic anion exchange resin D201 produced by Hangzhou Zhengguang Resin Factory, add it to the zirconium-titanium ion solution, set the temperature at 50°C, and stir at 180rpm under closed conditions for 12 hours;

[0068] S4 then, add 15g sodium hydroxide and 15g sodium chloride, 21g sodium hydroxide and 21g sodium chloride, 28g sodium hydroxide and 28g chlorine respectively in the solution of embodiment 1, embodiment 2 and comparative example A, B Sodium chloride, 56g sodium hydroxide and 56g sodium chloride, maintain the amount of adding sodium hydroxide and sodium chloride to be 5% by mass. Set the temperature at 50°C and stir at a speed of 180rpm for 3 hours; after the stirring is completed, the resin is filtered out an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com