Efficient cement grinding aid as well as preparation method and application thereof

A cement grinding aid and high-efficiency technology, applied in cement production, etc., can solve the problems of poor adaptability of cement and admixtures, poor water retention of cement, etc., to achieve the effect of improving water retention, increasing content, and reducing power consumption of the mill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

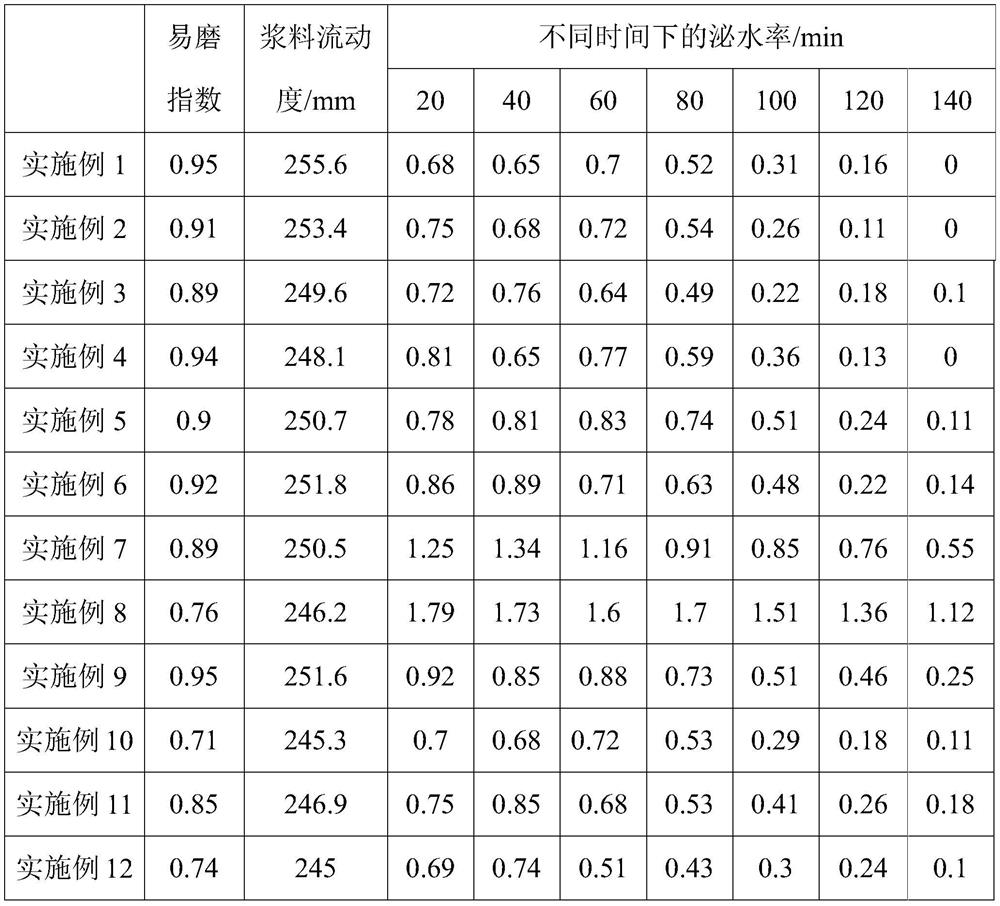

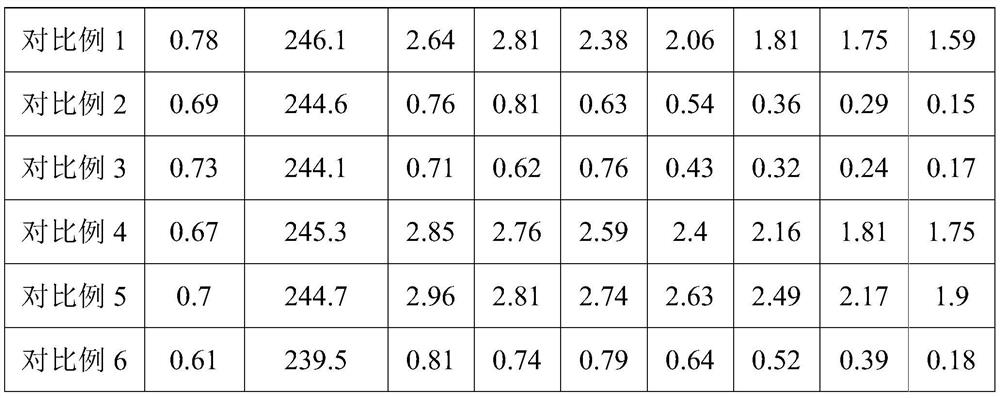

Examples

Embodiment 1

[0040] This embodiment provides a high-efficiency cement grinding aid, the composition of the high-efficiency cement grinding aid is: 18 parts of diethanol monoisopropanolamine, 12 parts of triethanolamine, 12 parts of glycerol, 8 parts Diethylene glycol, 7 parts of wood calcium, 7 parts of polyacrylamide, 0.3 parts of defoamer and 35.7 parts of water;

[0041] The preparation method of described efficient cement grinding aid specifically comprises:

[0042] Add 7 parts of polyacrylamide and 7 parts of wood calcium to 35.7 parts of water to dissolve and obtain a mixed solution, then add 18 parts of diethanol monoisopropanolamine, 12 parts of triethanolamine, 12 parts of glycerol and 8 parts of diethylene glycol Add it into the primary mixing solution to dissolve to obtain the secondary mixing solution, and finally add 0.3 parts of defoamer to the secondary mixing solution to dissolve to obtain the high-efficiency cement grinding aid.

Embodiment 2

[0044] This embodiment provides a high-efficiency cement grinding aid, the composition of the high-efficiency cement grinding aid is: 15 parts of diethanol monoisopropanolamine, 15 parts of triethanolamine, 10 parts of glycerol, 10 parts Diethylene glycol, 5 parts of wood calcium, 10 parts of polyacrylamide, 0.1 part of defoamer and 34.9 parts of water;

[0045] The preparation method of described efficient cement grinding aid specifically comprises:

[0046] Add 10 parts of polyacrylamide and 5 parts of wood calcium into 34.9 parts of water to dissolve and obtain a mixed solution, then add 15 parts of diethanol monoisopropanolamine, 15 parts of triethanolamine, 10 parts of glycerol and 10 parts of diethylene glycol Add it into the primary mixed solution to dissolve to obtain the secondary mixed solution, and finally add 0.1 part of defoamer to the secondary mixed solution to dissolve to obtain the high-efficiency cement grinding aid.

Embodiment 3

[0048] This embodiment provides a high-efficiency cement grinding aid, which is composed of: 20 parts of diethanol monoisopropanolamine, 10 parts of triethanolamine, 15 parts of glycerol, 5 parts Diethylene glycol, 10 parts of wood calcium, 5 parts of polyacrylamide, 0.5 parts of defoamer and 34.5 parts of water;

[0049] The preparation method of described efficient cement grinding aid specifically comprises:

[0050] Add 5 parts of polyacrylamide and 10 parts of wood calcium to 34.8 parts of water to dissolve and obtain a mixed solution, then add 20 parts of diethanol monoisopropanolamine, 10 parts of triethanolamine, 15 parts of glycerol and 5 parts of diethylene glycol Add it into the primary mixing solution to dissolve to obtain a secondary mixing solution, and finally add 0.5 parts of defoamer to the secondary mixing solution to dissolve to obtain the high-efficiency cement grinding aid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com