Laser welding joint defect TIG fusion repair process method

A technology of welding joints and process methods, applied in welding equipment, welding accessories, manufacturing tools, etc., to achieve the effects of ensuring the quality of welds, reducing stress concentration at the root, and eliminating defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

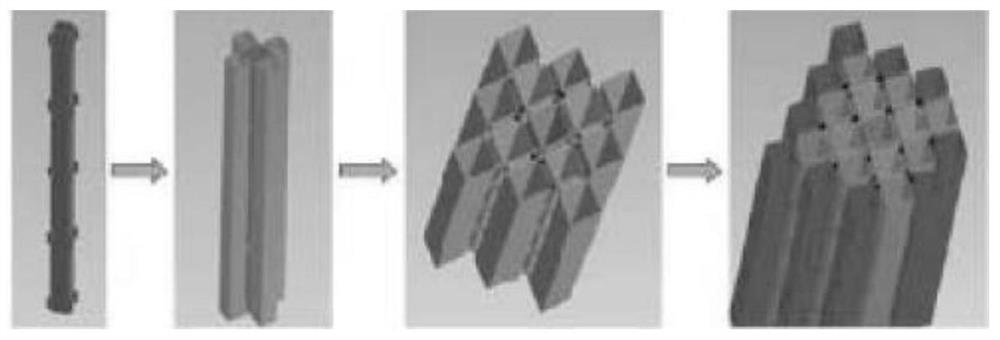

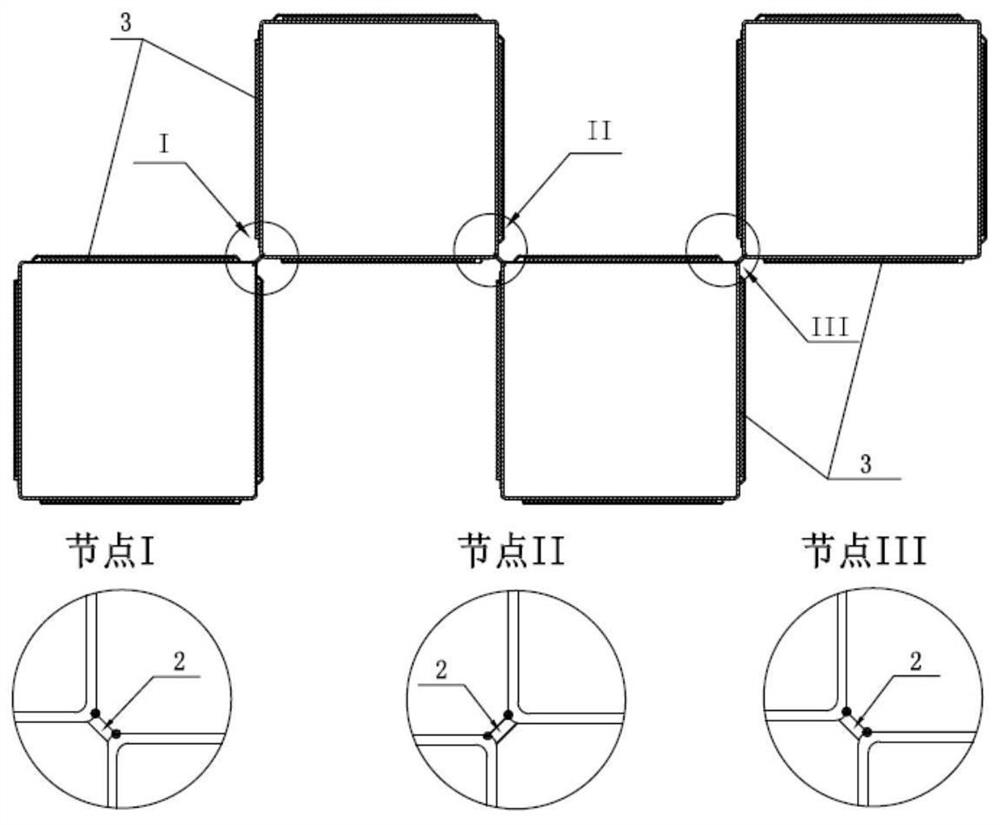

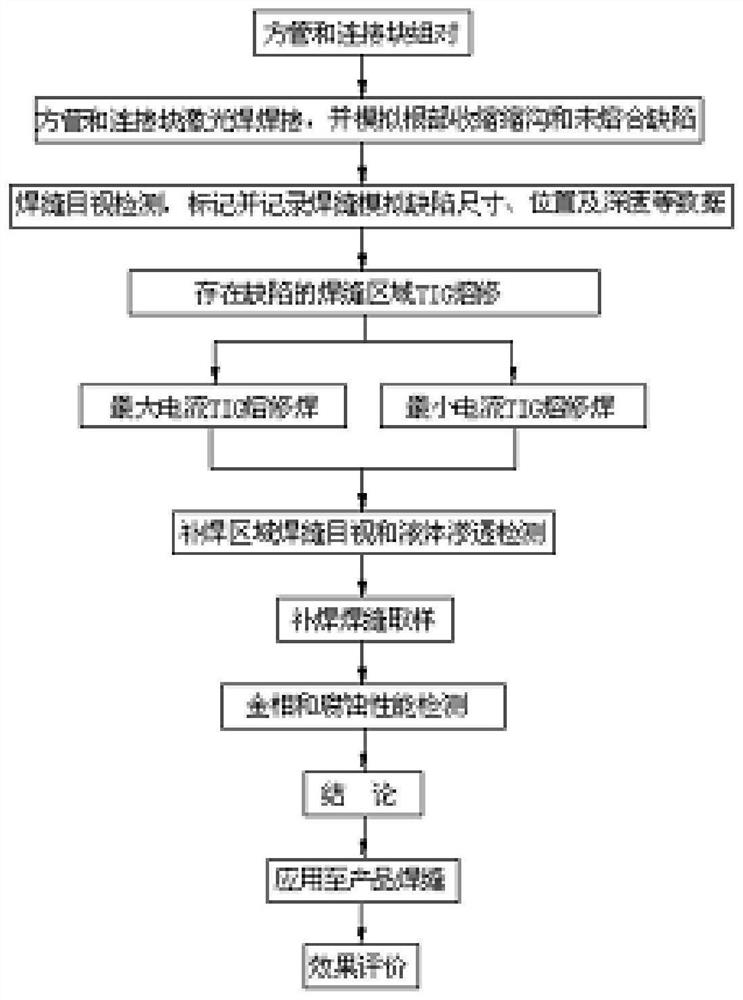

[0040] as attached Figure 3-7 Shown, a kind of laser welding welded joint defect TIG melting process method, comprises the following steps:

[0041] Step 1: Use the connecting plate and square tube welding test piece of the same specification, material and structure as the product for simulated welding. Firstly, the connecting plate and square tube are welded by laser welding, and the depth is made in the weld seam of the test piece. Shrinkage grooves at the root of about 0.5mm to 0.6mm, and unfused simulated defects with a depth of about 0.3mm.

[0042] Step 2: Remove oil stains, surface oxides and metal vapor residual pollutants in the welding defect area of the joint after laser welding, clean the part to be repaired with a wire brush, and then wipe it clean with an organic solvent (acetone or absolute ethanol).

[0043] Step 3: Fix the test piece with special tooling, and place the test piece at a distance of 4m to 4.5m from the welder, and place the camera group at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com