Centralized control device beside ship main propulsion device and control method

A technology of centralized control and propulsion, applied in the direction of propulsion engine, ship propulsion, propulsion components, etc., can solve the problems of unrealistic redesign or large-scale modification, high standardization of imported equipment, and lack of centralized control, so as to improve the efficiency of ships. The effect of vitality, small layout space requirements, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

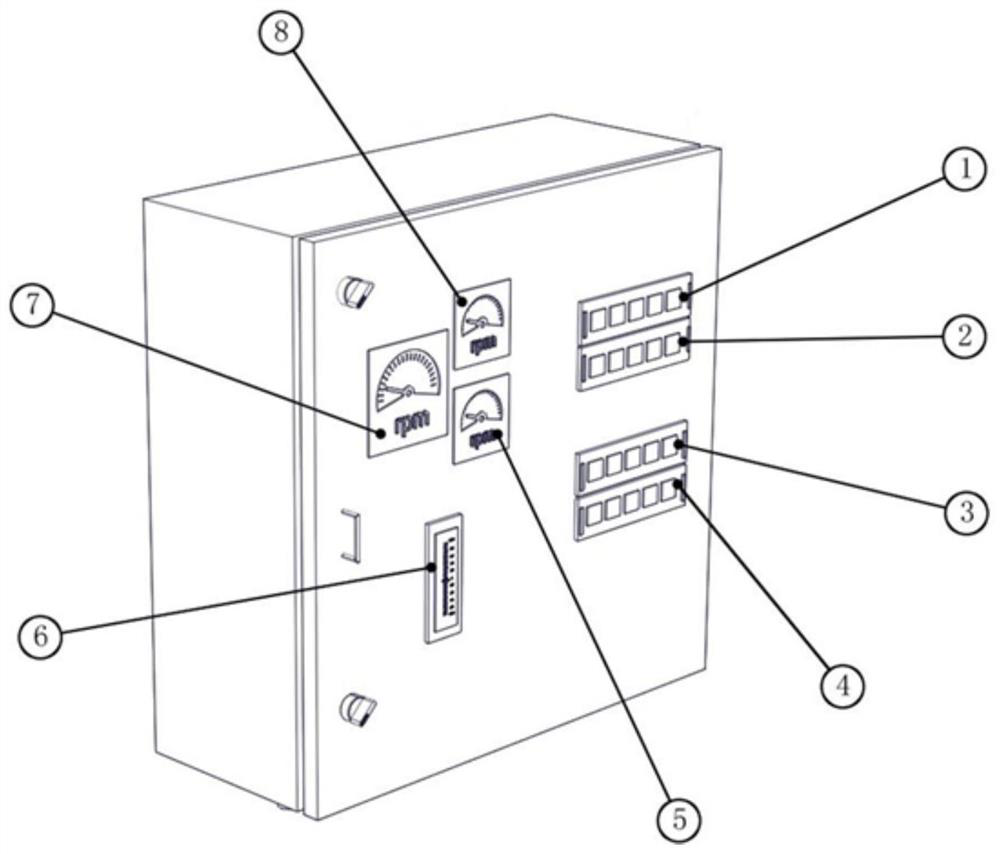

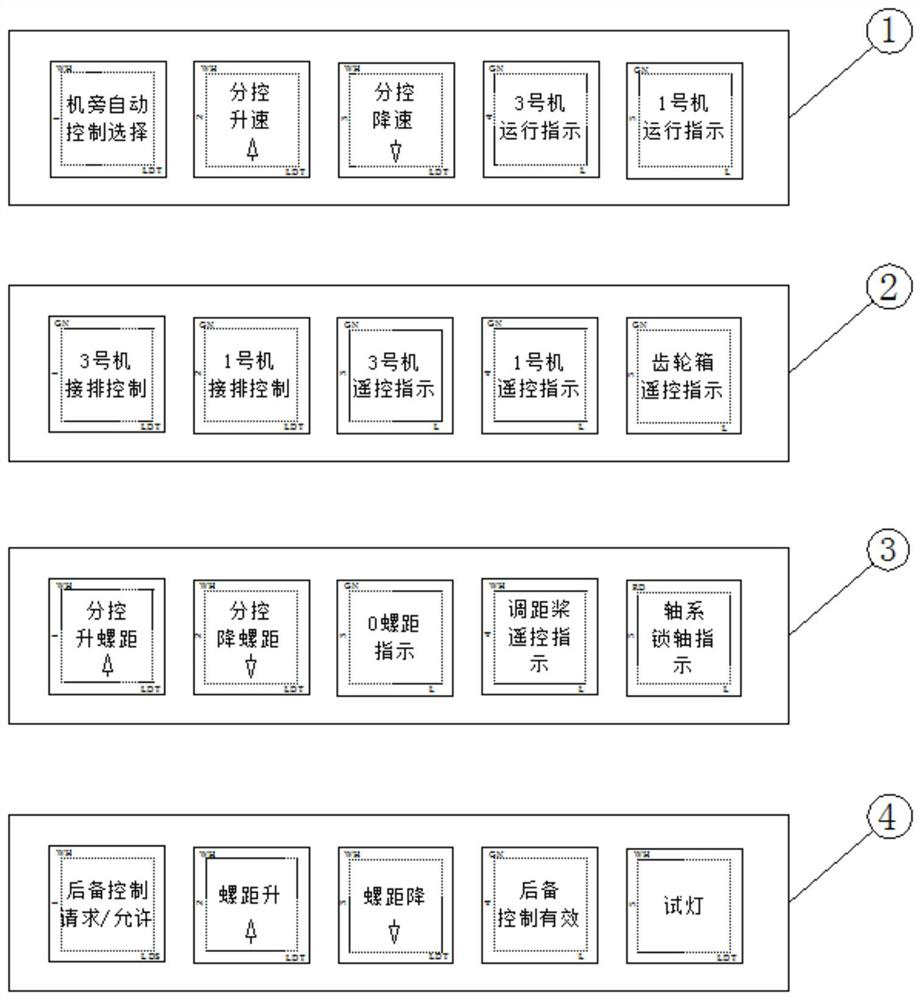

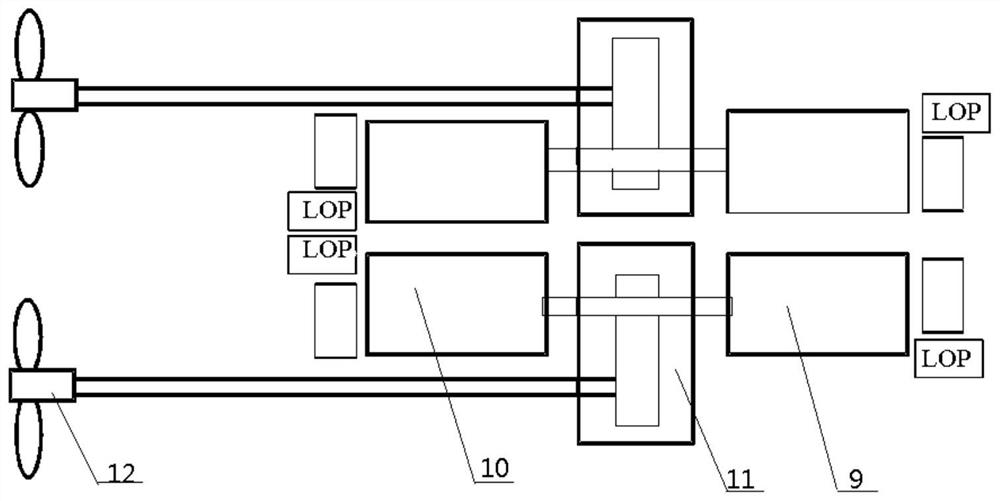

[0029] This embodiment provides a machine-side centralized control device for the main propulsion device of a ship, including a host control unit, a host control panel 1, a gearbox 11 control unit, a gearbox 11 control panel 2, a propeller shaft control unit, a propeller shaft control panel 3, Controlled pitch propeller 12 backup control unit, controllable pitch propeller 12 backup control panel 4, main machine tachometer 5, controllable pitch propeller 12 tachometer 6, shaft tachometer 7, coaxial main engine tachometer 8, the host control unit is used For control authority conversion and host speed control, the host control panel 1 is connected to the host control unit to realize the interaction between the user and the host control unit, and the gear box 11 control unit is used to realize the connection between the local host and the coaxial host. between the automatic load distribution; the gearbox 11 control panel 2 is used to realize the interaction between the user and th...

Embodiment 2

[0031] This embodiment provides a machine-side centralized control method for a main propulsion device of a ship, which includes the following steps:

[0032] Step 1. Control the machine-side centralized control device through the host control panel 1 to obtain local-level remote control authority; the control authority level of the machine-side centralized control device is higher than that of the central control room control station and the cab control station.

[0033] Step 2. Control the main machine (No. 1 machine 9) to connect to the row through the control panel 1 of the main machine. The speed of the main machine of this machine is automatically adjusted to the speed of the first machine to connect to the row and automatically connect to the row; specifically: press No. 1 machine 9 to connect to the row. button, the speed of No. 1 machine 9 is automatically adjusted to the speed of the first machine to connect to the row and automatically connect to the row. After conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com