Process for removing free quartz from coal series kaolin

A coal-based kaolin and free quartz technology, which is applied in the field of coal-based kaolin free quartz removal technology, can solve the problems of high resource consumption, ineffective removal, and low quartz removal rate, and achieve the effects of improving utilization efficiency and reducing environmental protection and safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

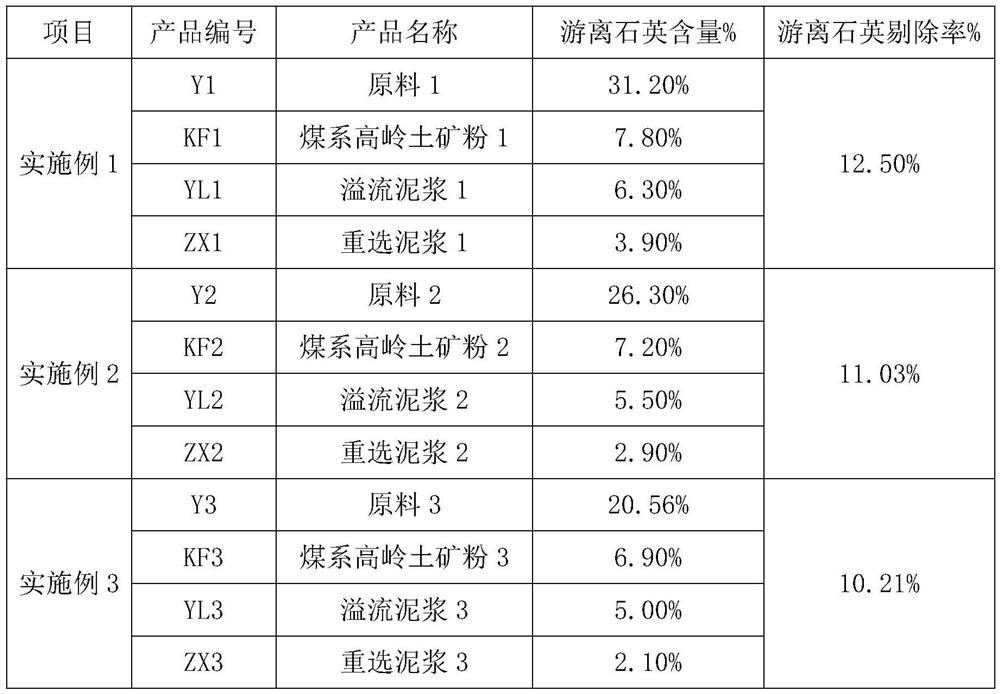

Embodiment 1

[0030] A coal series kaolin free quartz removal process, wherein: comprising the following steps:

[0031] (1) One-time elimination: the coal-measure kaolinite ore is crushed three times in turn to a fineness of 1mm, and the ratio of raw material fineness after three crushings is 300:30:1, and then the crushed ore The powder is sieved through a 20-mesh sieve to obtain primary crushed raw materials;

[0032] (2) Secondary removal: The primary crushed raw materials obtained in step (1) are ground through grinding equipment to obtain coal-based kaolin powder. The grinding fineness is controlled at 200-300 mesh, and the powder below 200 mesh is passed The slag outlet of the grinding equipment is discharged; the separated effective coal-measure kaolin powder free quartz is passed through the X-ray diffractometer, and the experimental measurement is 7.8%.

[0033] (3) Three times of elimination: mix the 200-300 mesh coal series kaolin slag obtained in step (2), water and dispersant...

Embodiment 2

[0043] A coal series kaolin free quartz removal process, wherein: comprising the following steps:

[0044] (1) One-time elimination: the coal-measure kaolinite ore is crushed three times in sequence to a fineness of 1mm, and the ratio of raw material fineness after three crushings is 400:40:2, and then the crushed ore The powder is sieved through a 20-mesh sieve to obtain primary crushed raw materials;

[0045] (2) Secondary removal: The primary crushed raw materials obtained in step (1) are ground through grinding equipment to obtain coal-based kaolin powder. The grinding fineness is controlled at 200-300 mesh, and the powder below 200 mesh is passed The slag outlet of the grinding equipment is discharged; the separated effective coal-measure kaolin powder free quartz is passed through the X-ray diffractometer, and the experimental measurement is 7.2%.

[0046] (3) Three times of elimination: the 200-300 mesh coal series kaolin powder, water and dispersant obtained in step (...

Embodiment 3

[0056] A coal series kaolin free quartz removal process, wherein: comprising the following steps:

[0057] (1) One-time elimination: the coal-measure kaolinite ore is crushed three times in sequence to a fineness of 1mm, and the ratio of raw material fineness after three crushings is 500:50:3, and then the crushed ore The powder is sieved through a 20-mesh sieve to obtain primary crushed raw materials;

[0058] (2) Secondary removal: The primary crushed raw materials obtained in step (1) are ground through grinding equipment to obtain coal-based kaolin powder. The grinding fineness is controlled at 200-300 mesh, and the powder below 200 mesh is passed Discharged from the slag outlet of the grinding equipment; the separated effective coal-measure kaolin powder free quartz was determined to be 6.9% by X-ray diffractometer.

[0059] (3) Three times of elimination: mix the 200-300 mesh coal series kaolin powder, water and dispersant obtained in step (2) to obtain a slurry with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com