Ultrahigh-strength cast aluminum alloy hub material ZL350/500 and manufacturing technology thereof

A technology for casting aluminum alloy and manufacturing process, applied in the field of new aluminum alloy materials and casting aluminum alloy, can solve problems such as low material strength, and achieve the effect of increased strength, wear resistance, and increased fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Ultra-high-strength cast aluminum alloy ZL350 / 500, its composition by weight percentage is: Si: 12.5%; Fe: 0.3%; Cu: 1.9%; Mn: 0.25%; Mg: 1.7%; Zr: 0.01%; Zn: 0.18 %; Ti: 0.55%; Ni≤0.05; the balance is aluminum.

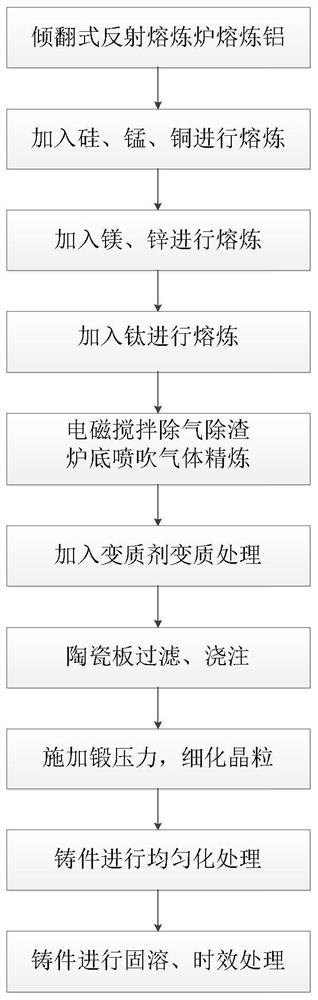

[0057] Its manufacturing method comprises the following steps:

[0058] (1) The tilting reflective melting furnace melts aluminum, and the NOX is lower than 60ppm;

[0059] (2) When part of the charge is melted, add 12.5% silicon, 0.25% manganese and 1.9% copper to the melt at 725°C to 740°C for smelting;

[0060] (3) When the temperature rises to 730°C to 750°C, sprinkle powdery solvent, separate slag and metal, and carry out slag removal. After removing slag, add 1.7% magnesium and 0.18% zinc for smelting;

[0061] (4) After the temperature rises to 740°C to 760°C, add 0.55% titanium for smelting;

[0062] (5) After the various ingredients are fully dissolved together, start the electromagnetic stirrer to stir, the number of stirring is not less than 4 ...

Embodiment 2

[0073] Ultra-high-strength cast aluminum alloy ZL350 / 500, its composition by weight percentage is: Si: 10%; Fe: 0.25%; Cu: 2.8%; Mn: 0.3%; Mg: 2.1%; Zr: 0.05%; Zn: 0.3 %; Ti: 0.2%; Ni≤0.05; the balance is aluminum.

[0074] Its manufacturing method comprises the following steps:

[0075] (1) The tilting reflective melting furnace melts aluminum, and the NOX is lower than 60ppm;

[0076] (2) When part of the charge is melted, add 10% silicon, 0.3% manganese and 2.8% copper to the melt at 720°C to 740°C for smelting;

[0077] (3) When the temperature rises to 740°C to 750°C, sprinkle powdery solvent, separate slag and metal, and carry out slag removal. After removing slag, add 2.1% magnesium and 0.30% zinc for smelting;

[0078] (4) After the temperature rises to 750°C to 760°C, add 0.2% titanium for smelting;

[0079] (5) After the various ingredients are fully dissolved together, start the electromagnetic stirrer to stir, the number of stirring is not less than 4 times, and...

Embodiment 3

[0090] Ultra-high-strength cast aluminum alloy ZL350 / 500, its composition by weight percentage is: Si: 7%; Fe: 0.45%; Cu: 3.2%; Mn: 0.45%; Mg: 2.5%; Zr: 0.03%; Zn: 0.15 %; Ti: 0.35%; Ni≤0.05; the balance is aluminum.

[0091] Its manufacturing method comprises the following steps:

[0092] (1) The tilting reflective melting furnace melts aluminum, and the NOX is lower than 60ppm;

[0093] (2) When part of the charge is melted, add 7% silicon, 0.45% manganese and 3.2% copper to the melt at 730°C to 740°C for smelting;

[0094] (3) When the temperature rises to 740°C to 750°C, sprinkle powdery solvent, separate slag and metal, carry out slag removal, add magnesium 2.5% and zinc 0.15% after slag removal for smelting;

[0095] (4) After the temperature rises to 750°C to 760°C, add 0.35% titanium for smelting;

[0096] (5) After the various ingredients are fully dissolved together, start the electromagnetic stirrer to stir, the number of stirring is not less than 4 times, and ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com