Constant-volume electric control combustion coupling meshing engine

An internal combustion engine and electronic control technology, applied in the direction of machines/engines, mechanical equipment, etc., to achieve the effects of eliminating alternating side pressure, improving conversion efficiency, and increasing useful power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention mainly implements a fundamental innovation on the transmission conversion mechanism of the engine, and the gas distribution mechanism, fuel supply system, ignition system, intake and exhaust system, cooling system, starting system, and computer control system of the engine can be completely transplanted or used for reference. There are mature products and technologies for engines.

[0034] The present invention is specifically implemented according to the accompanying drawings:

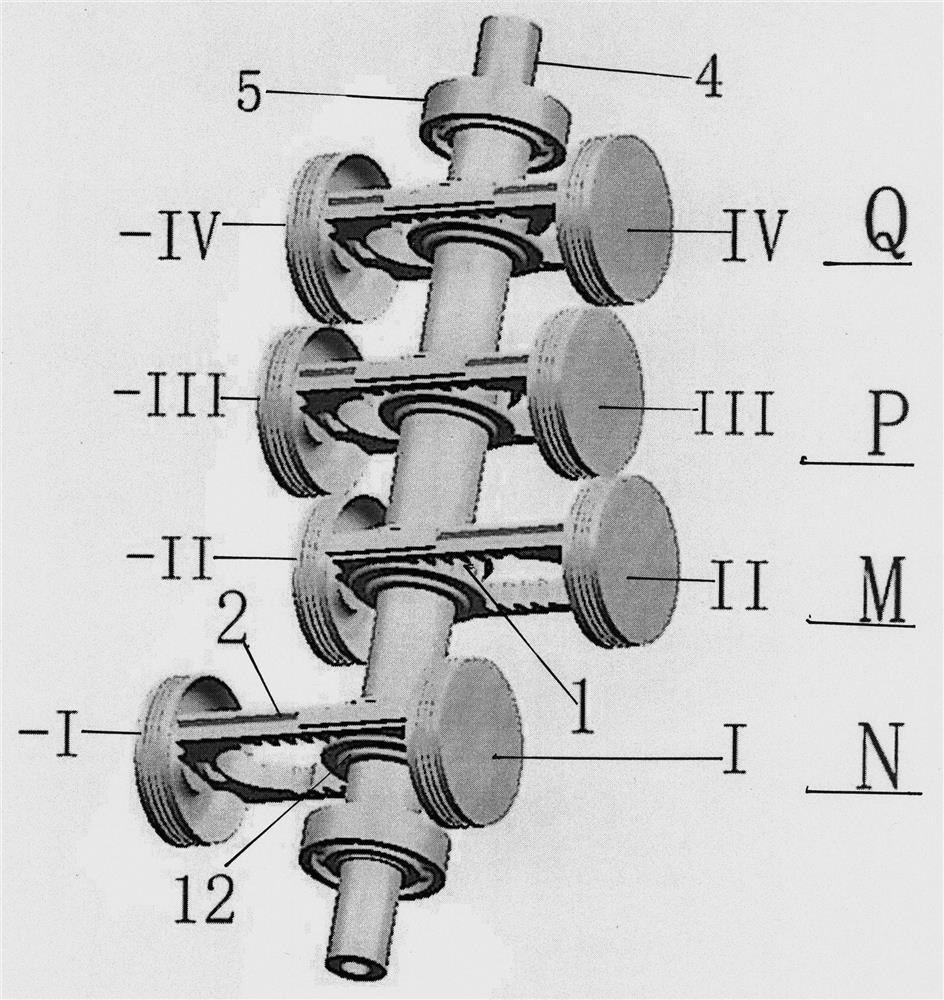

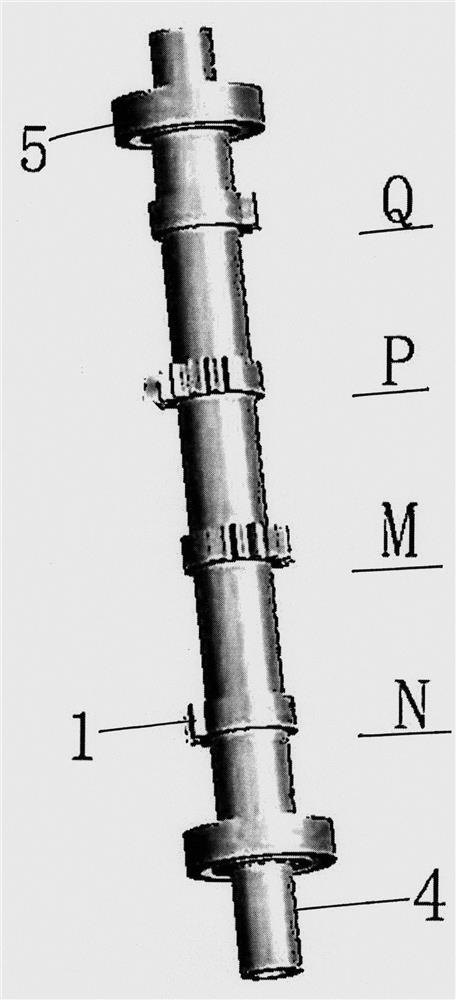

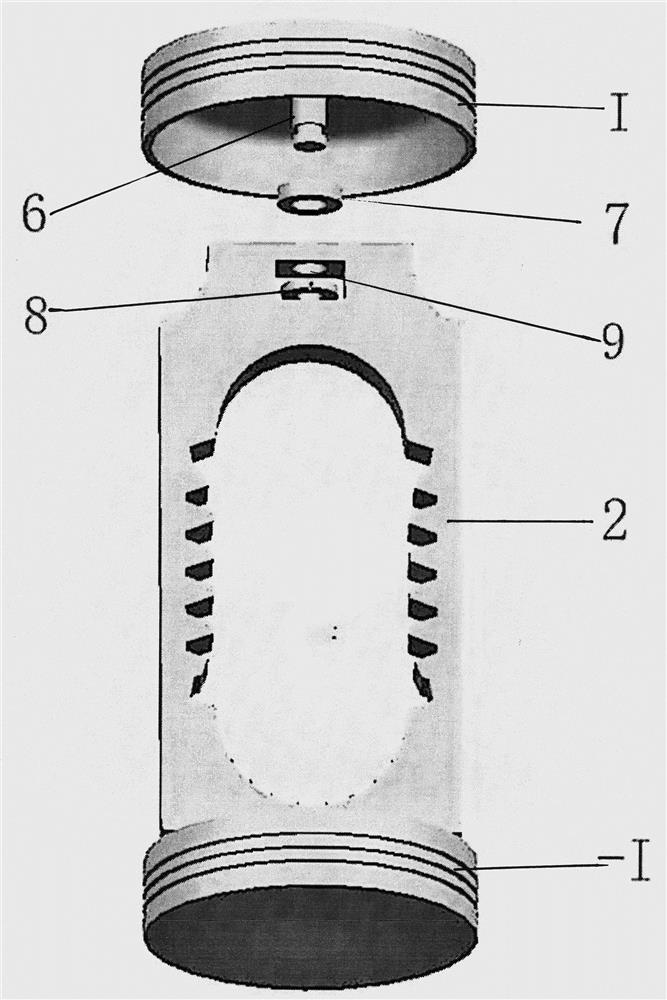

[0035] attached figure 1 The improved engine output shaft 4 shown is a hollow straight shaft, with ball bearings 5 positioned on the body at both ends, pistons I, II, III, and IV are arranged on one side of the central shaft, and -I in the opposite direction is arranged symmetrically on the other side. , -II, -III, -IV pistons. The cylinder sleeve corresponding to the piston is arranged on the body on both sides of the central output shaft. The position of the piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com