Multi-carnassial-tooth-ratio multi-port magnetic field modulation motor

A magnetic field modulation, multi-port technology, applied in the direction of motors, magnetic circuits, electric components, etc., can solve the problems of difficult to apply multi-port differential output occasions, low motor operation efficiency, limited application scope, etc., to improve the utilization rate of wires ,Easy to dissipate heat and reduce usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

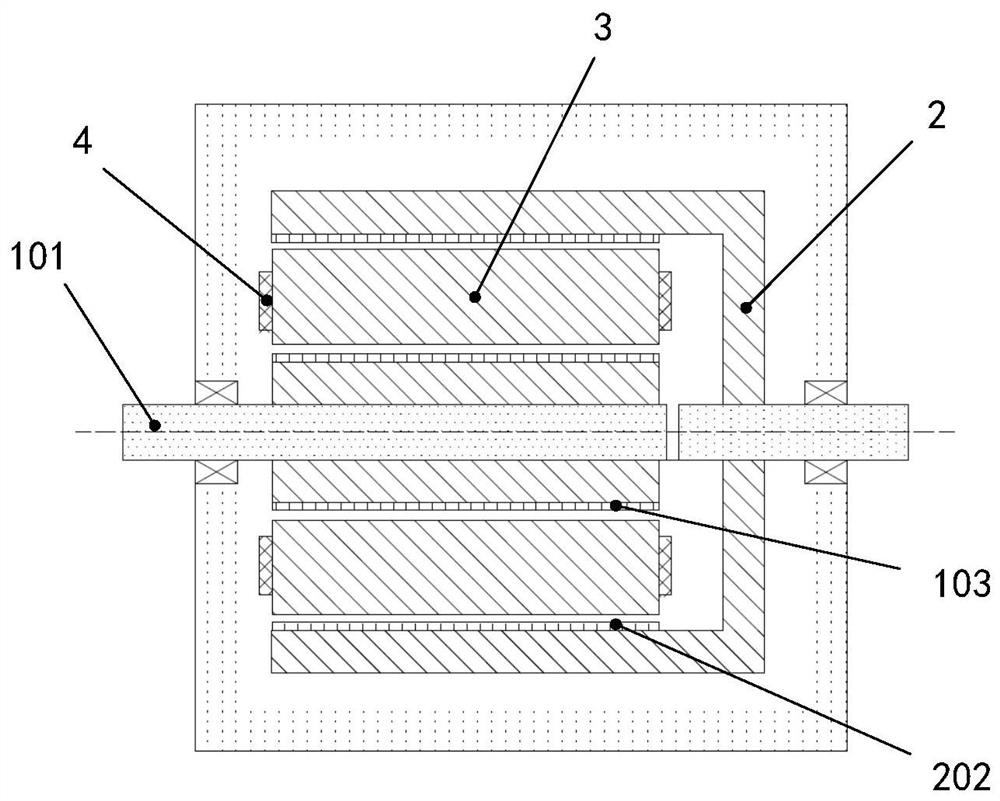

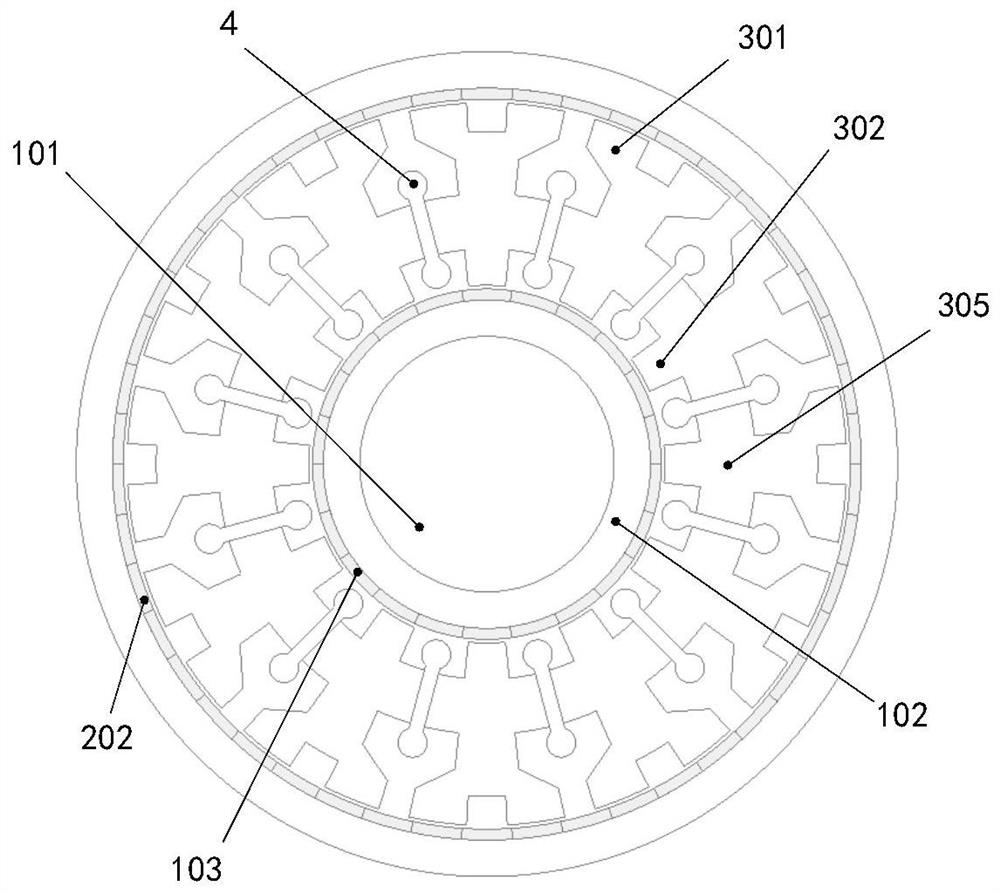

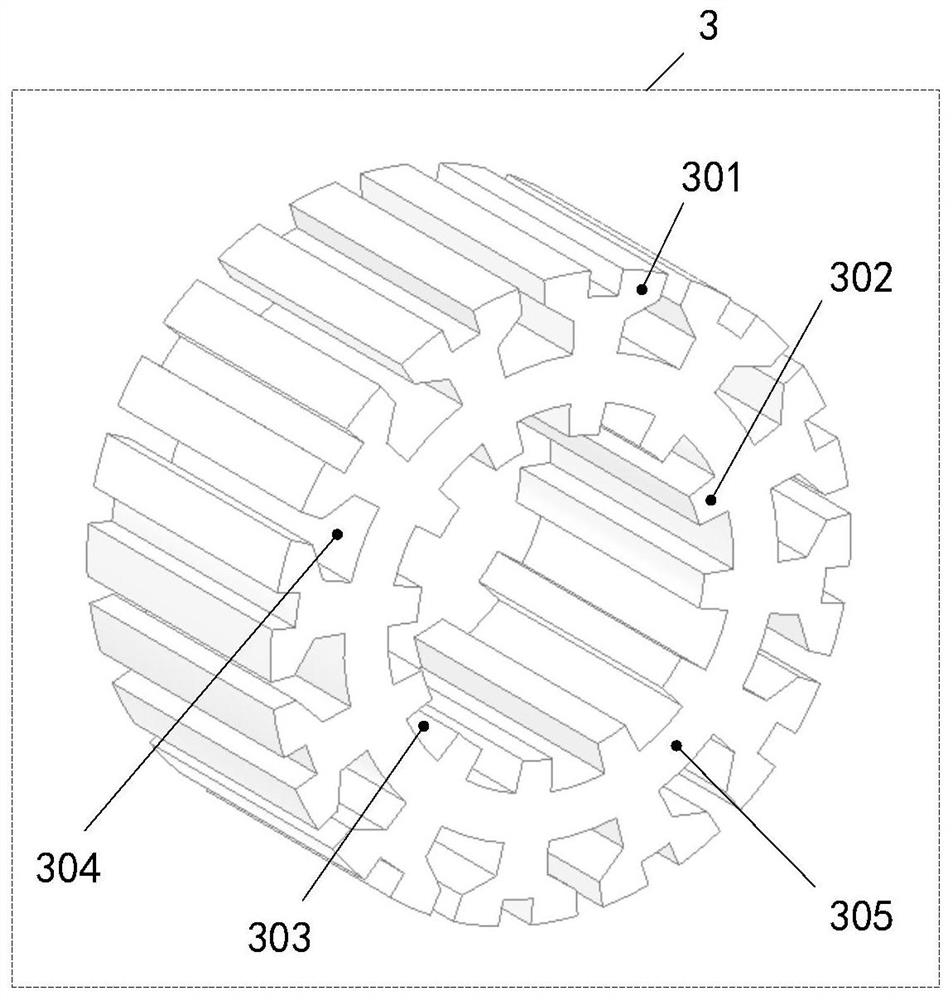

[0067] Such as figure 1 , figure 2 As shown, the present invention discloses a multi-split gear ratio multi-port magnetic field modulation motor, which includes a multi-split gear ratio stator 3, a ring winding 4, an inner rotor 1, an inner rotor permanent magnet 103, a rotating shaft 101, an outer rotor 2 and Outer rotor permanent magnet 202. The first layer of air gap is located between the inner rotor permanent magnet 103 and the multi-splitting gear ratio stator 3, and the second layer of air gap is located between the outer rotor permanent magnet 202 and the multi-splitting gear ratio stator 3; the inner and outer surfaces of the stator yoke 305 are along the The stator teeth are evenly distributed on the circumference, and the inner and outer layers of stator teeth are split or combined to form modulation teeth with different numbers; the inner and outer modulation teeth are arranged at even intervals to form stator outer slots 304 and stator inner slots 303, and the ...

Embodiment 2

[0076] Such as Figure 12 , 13 As shown, the present invention further discloses the second structure of the multi-splitting gear ratio multi-port magnetic field modulation motor, which adopts two stator electrical ports and one rotor 9 mechanical output port. The motor includes an outer stator 6 , an inner stator 5 , an outer stator winding 8 , an inner stator winding 7 , a rotor 9 and a rotating shaft 101 . The first layer of air gap is located between the inner stator 5 and the rotor 9, and the second layer of air gap is located between the rotor 9 and the outer stator 6; the inside of the outer stator 6 and the outside of the inner stator 5 are evenly distributed along the circumferential direction. 1. The outer stator teeth are split or merged to form modulation teeth with different numbers; the inner and outer modulation teeth are arranged at even intervals to form outer stator slots 602 and inner stator slots 502, the outer stator windings 8 are embedded in the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com