Novel extraction method and system for coix seeds

An extraction method and extraction system technology, applied in the field of new coix seed extraction method and its extraction system, can solve problems such as process interruption, energy waste, and high exhaust gas temperature, and achieve the goals of reducing heat energy consumption, ensuring continuity, and improving utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

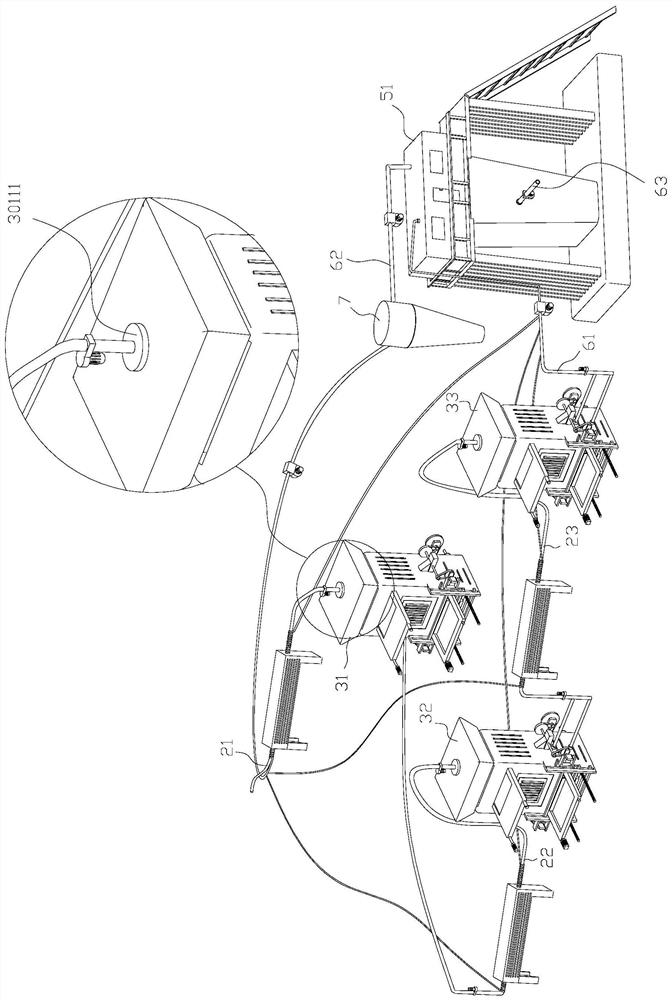

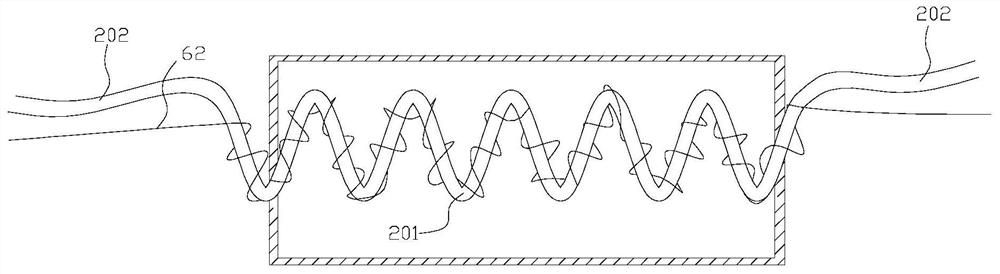

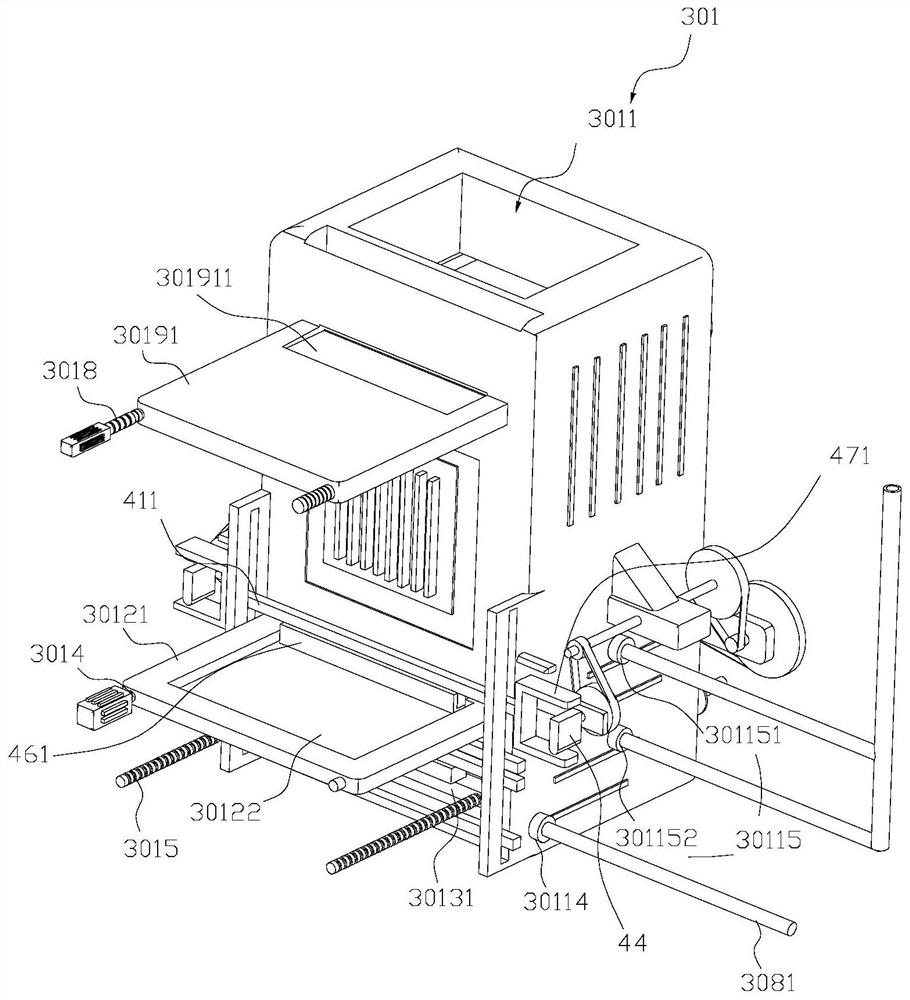

[0083] This embodiment discloses a new method for extracting coix seed, which includes the following steps: the enzymatic hydrolyzate obtained from the treatment of coix seed flows into a membrane separation system through a spiral or retracement path for membrane separation. The retentate separated by the membrane separation system is spray-dried, and the waste gas generated by the spray-drying is heat-exchanged with the enzymatic hydrolysis liquid in the spiral or retracement path, and then sprayed to the rotating mechanism to drive the atomizing nozzle to rotate.

[0084] The membrane separation system includes a plurality of membrane separators, and the enzymatic hydrolysis solution passes through the plurality of membrane separators in sequence, and two adjacent membrane separators are connected through a spiral or a return path.

[0085] The two sets of filter membranes in the same membrane separator can alternately separate the enzymolysis solution, ensuring that the enz...

Embodiment 2

[0118] This embodiment discloses a novel extraction method of coix seed, comprising the following steps:

[0119] Step 1. Crush coix seed and sieve it to 80 mesh, add purified water to wet granulate, sieve to 10 mesh and then dry. The mass ratio of purified water to coix seed is 3:5; use supercritical CO 2 Extraction technology for extraction: the pressure of the extraction kettle is 25Mpa, the temperature is 40°C, the pressure of the separation kettle is 8Mpa, the temperature is 45°C, the flow rate is 110L / h, and the extraction time is 4h, and the degreased intermediate, coix seed ester and coix seed oil are obtained;

[0120] Step 2. The degreased intermediate and purified water are mixed according to the mass ratio of 1:12 to obtain a mixed solution, and high-temperature-resistant α-amylase is added to the mixed solution, and the concentration of the high-temperature-resistant α-amylase in the mixed solution is 0.015g / 100mL , and extracted at 90°C for 2 hours, inactivated a...

Embodiment 3

[0126] This embodiment discloses a novel extraction method of coix seed, comprising the following steps:

[0127] Step 1. Crush coix seed and sieve it to 80 mesh, add purified water to wet granulate, sieve to 10 mesh and then dry. The mass ratio of purified water to coix seed is 3:5; use supercritical CO 2 Extraction technology for extraction: the pressure of the extraction kettle is 25Mpa, the temperature is 40°C, the pressure of the separation kettle is 8Mpa, the temperature is 45°C, the flow rate is 110L / h, and the extraction time is 4h, and the degreased intermediate, coix seed ester and coix seed oil are obtained;

[0128] Step 2. The degreased intermediate and purified water are mixed according to the mass ratio of 1:12 to obtain a mixed solution, and high-temperature-resistant α-amylase is added to the mixed solution, and the concentration of the high-temperature-resistant α-amylase in the mixed solution is 0.015g / 100mL , and extracted at 90°C for 2 hours, inactivated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com