Method for regulating and controlling quick demulsification and restabilization of emulsion without using surfactant

An emulsion and demulsification technology, applied in chemical instruments and methods, mixing methods, dissolution and other directions, can solve the problems of high cost and large amount of surfactant, and achieve the effect of low cost, wide application and lower use cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: n-decane / water emulsion stabilized by nano silicon dioxide particles and n-octylamine composite emulsifier.

[0037] Disperse 0.021g of nano-silica particles (0.3wt.%) in n-octylamine solutions with concentrations of 0.5, 1, 1.5, 2, 3 and 6mmol / L, and add 3mL of n-decylamine at a volume ratio of 1:1 to water. Alkanes were homogenized at 11,000 rpm for 2 minutes using a homogenizer to obtain a stable emulsion.

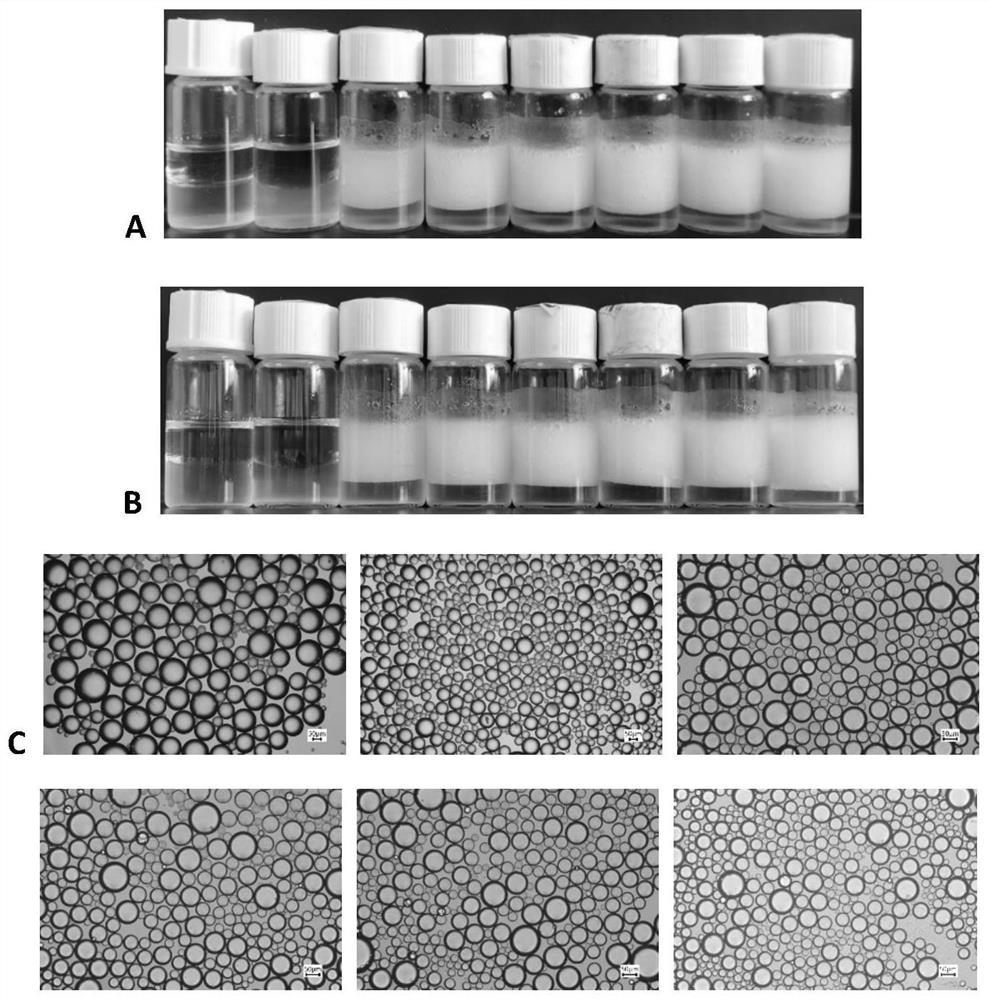

[0038] like figure 1 As shown, the emulsion cannot be stabilized in the presence of nano-silica particles alone, and the stable emulsion cannot be formed in the presence of n-octylamine alone. The nano-silica particles are dispersed in n-octylamine solution to form a composite emulsifier, and a stable O / W emulsion can be obtained when the n-octylamine concentration is above 0.5mmol / L. And with the increase of n-octylamine concentration, the particle size of the dispersed phase in the emulsion becomes smaller. After standing for six months, the appea...

Embodiment 2

[0039] Example 2: n-decane / water emulsion stabilized by nano-alumina particles and n-octylamine composite emulsifier.

[0040] 0.021g of nano-alumina particles (0.3wt.%) is dispersed in the n-octylamine solution whose concentration is 0.001, 0.003, 0.006, 0.01, 0.03, 0.06, 0.1, 0.3, 0.6, 1, 3 and 6mmol / L, Add 3 mL of n-decane at an oil-water volume ratio of 1:1, and use a homogenizer to homogenize at 11,000 rpm for 2 minutes to obtain a stable emulsion.

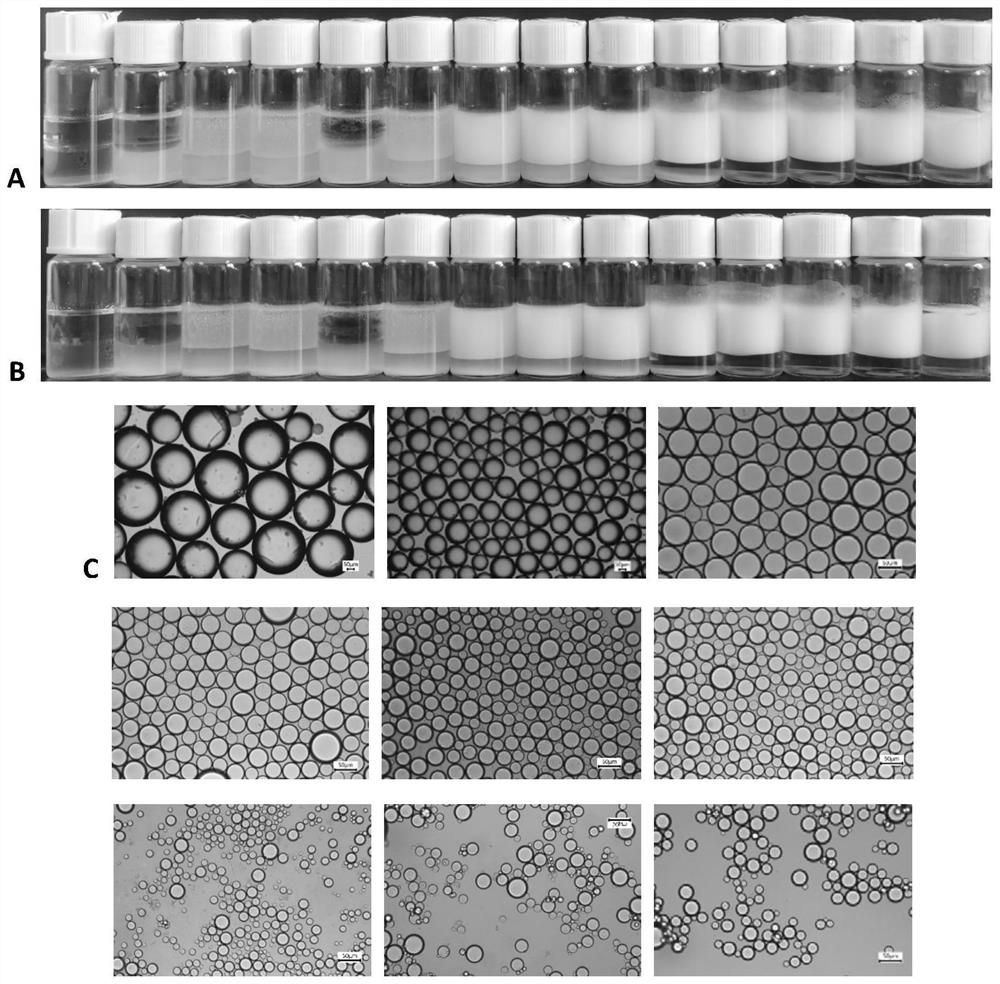

[0041] like figure 2 As shown, the emulsion cannot be stabilized in the presence of nano-alumina particles alone, and the stable emulsion cannot be formed in the presence of n-octylamine alone. Disperse the nano-alumina particles into the n-octylamine solution to form a composite emulsifier. When the n-octylamine concentration is above 0.03mmol / L, a stable O / W emulsion can be obtained. And with the increase of n-octylamine concentration, the particle size of the dispersed phase in the emulsion becomes smaller. After stand...

Embodiment 3

[0042] Embodiment 3: the n-decane / water emulsion that nano-silica particles and N, N dimethyl hexadecylamine stabilize

[0043] Prepare the n-decane / water system of 0.3wt.% nano-silica particles and 0.001, 0.01, 0.1, 1 and 10mmol / L N, N dimethyl hexadecylamine, using a homogenizer Homogenize for 2 minutes at 11000 rpm to obtain a stable emulsion.

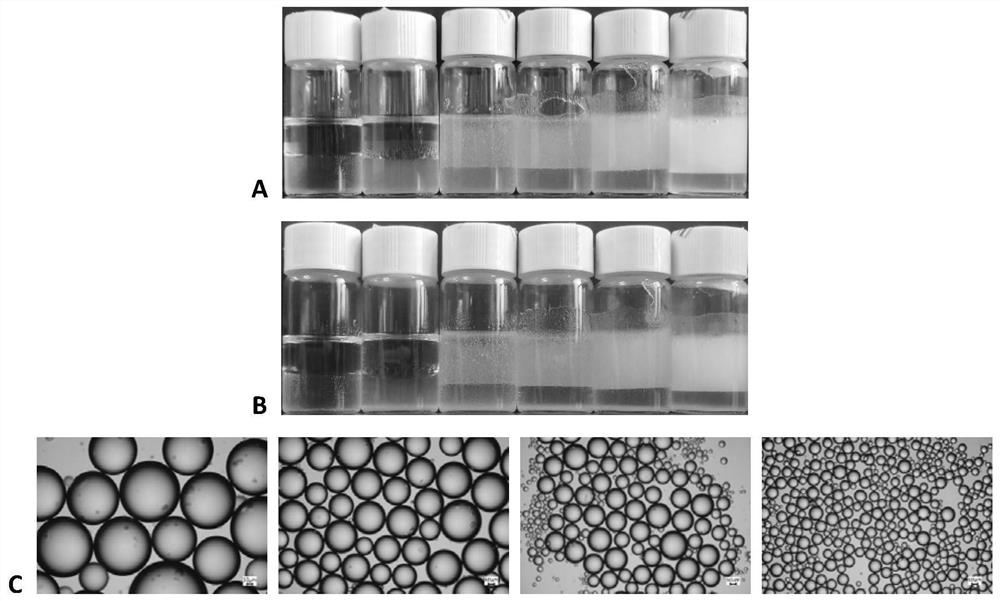

[0044] like image 3 As shown, the emulsion cannot be stabilized in the presence of nano-silica particles alone, and the stable emulsion cannot be formed in the presence of N,N dimethyl hexadecylamine alone. The emulsifier formed after the two are compounded can prepare a stable O / W emulsion when the concentration of N,N dimethyl hexadecylamine is above 1mmol / L. And with the increase of N,N dimethyl hexadecylamine concentration, the particle size of the dispersed phase in the emulsion becomes smaller. After standing for six months, the appearance of the emulsion remained basically unchanged, indicating that the obtained emulsion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com