High-frequency low-loss modified polyphenyl ether-based composite material

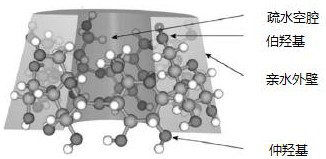

A composite material and polyphenylene ether technology, applied in the direction of non-polymer adhesive additives, adhesive types, adhesive additives, etc., can solve problems such as uneven distribution of cross-linking points, few practical applications, and affecting application effects , to achieve the effect of simple and easy modification method, improving solvent resistance and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

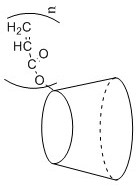

[0039] 1) Preparation of acryloyl-modified cyclodextrin monomer: Add 200ml dimethylformamide to 22.6g β-cyclodextrin, stir it with magnetic force to dissolve it completely, then add 30ml triethylamine dropwise and place in ice at 0°C Stir magnetically in a water bath for 5 minutes. Under the condition of nitrogen protection, slowly add 6ml of acryloyl chloride dropwise to the solution with a constant pressure dropping funnel, and react for 40 minutes at room temperature after the addition is completed. A solid was precipitated, and the filtrate was precipitated with acetone and then suction-filtered again. The obtained white solid was washed with acetone and suction-filtered. The final product was dried in a vacuum oven to constant weight. The average acryloyl functionality of the obtained modified cyclodextrin molecule was 3.

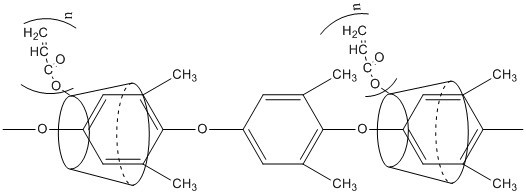

[0040] 2) Preparation of polyphenylene ether / acryloyl-modified cyclodextrin complex: step 1) 14g of acryloyl-modified cyclodextrin obtained, add 80ml o...

Embodiment 2

[0043] 1) Preparation of acryloyl-modified cyclodextrin monomer: Add 200ml dimethylformamide to 26g γ-cyclodextrin, stir it with magnetic force to dissolve it completely, then add 30ml triethylamine dropwise and place in an ice-water bath at 0°C Stir with medium magnetic force for 5 minutes. Under the condition of nitrogen protection, slowly add 8ml of acryloyl chloride to the solution with a constant pressure dropping funnel. After the addition is completed, react at room temperature for 60 minutes. solid, the filtrate was precipitated with acetone and filtered again, the white solid obtained was washed with acetone and filtered, and the final product was dried in a vacuum oven to constant weight. The obtained modified cyclodextrin molecule had an average acryloyl functionality of 4.

[0044] 2) Preparation of polyphenylene ether / acryloyl-modified cyclodextrin complex: step 1) 15.7g of acryloyl-modified cyclodextrin obtained, add 80ml of deionized water and grind in a colloid ...

Embodiment 3

[0047] 1) Preparation of acryloyl-modified cyclodextrin monomer: Add 250ml dimethylformamide to 26g γ-cyclodextrin, stir it with magnetic force to completely dissolve it, then add 30ml triethylamine dropwise and place in an ice-water bath at 0°C Stir under medium magnetic force for 10 minutes, and under the condition of nitrogen protection, slowly add 10ml of acryloyl chloride to the solution with a constant pressure dropping funnel, and react at room temperature for 60 minutes after the addition is completed. solid, the filtrate was precipitated with acetone and then suction filtered again, the obtained white solid was washed with acetone and suction filtered, and the final product was dried in a vacuum oven to constant weight, and the average acryloyl functionality of the obtained modified cyclodextrin molecule was 5.

[0048] 2) Preparation of polyphenylene ether / acryloyl-modified cyclodextrin complex: step 1) 16g of acryloyl-modified cyclodextrin obtained, add 100ml of deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com