Flame-retardant EVA shoe material for leisure shoes and preparation method thereof

A technology for casual shoes and shoe materials, applied in footwear, applications, clothing and other directions, can solve problems such as obvious flammability and large fire hazards, achieve good flame retardant and smoke suppression effects, reduce total smoke generation, and improve physical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

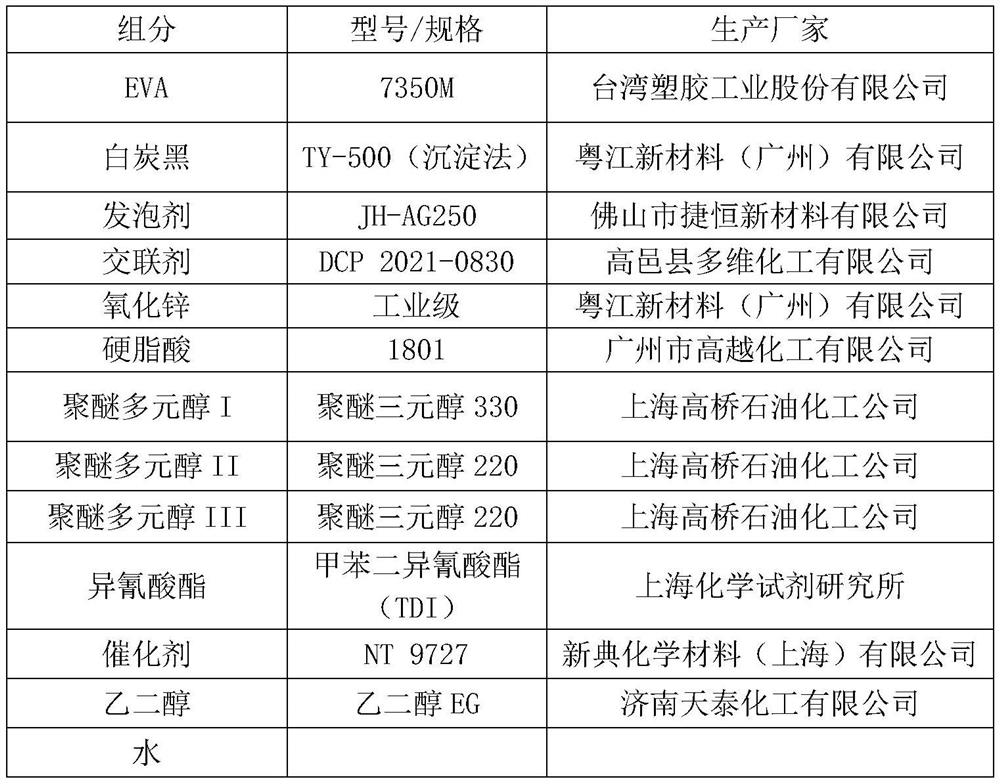

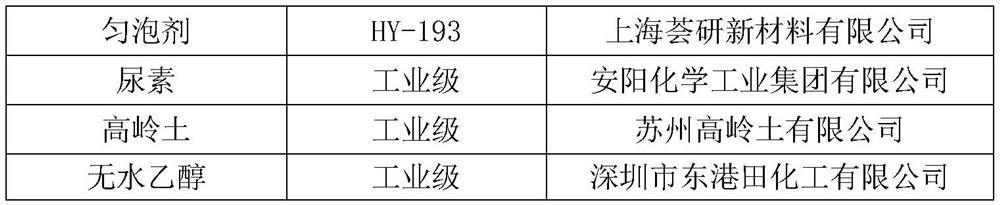

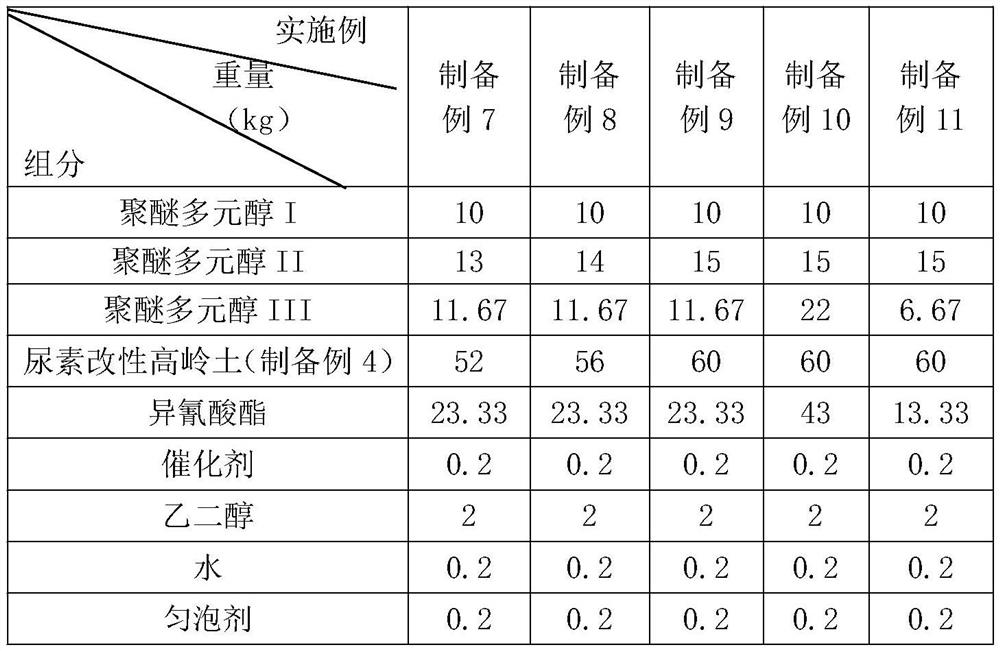

[0036] The weight ratio of components in Preparation Examples 7-11 of a modified polyurethane elastomer is shown in Table 2.

[0037] Concrete components and weight of table 2 preparation example 7-11

[0038]

[0039] Table 3 shows the weight ratio of components in Examples 1-8 of a flame-retardant EVA shoe material used for casual shoes.

[0040] Concrete component and weight of table 3 embodiment 1-8

[0041]

preparation example 1

[0044]A preparation method of urea-modified kaolin, comprising the following steps: the mass ratio of kaolin and urea solution is 1:2; taking a certain amount of kaolin and 70% mass concentration of urea solution in proportion, and adopting mechanical stirring and ultrasonic-assisted modification method, at 50°C, react for 3 hours, after stirring and ultrasonic treatment, filter the mixture under reduced pressure, wash the modified product with absolute ethanol 6 times, dry at 100°C for 12 hours, crush, and sieve to obtain Urea modified kaolin.

preparation example 2

[0046] A method for preparing urea-modified kaolin differs from Preparation Example 1 in that: Preparation Example 2 has a urea solution with a mass concentration of 75%, and reacts at 60° C. for 4.5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com