Modified expanded graphite-hydrated inorganic salt composite phase change material as well as preparation method and application thereof

A technology of composite phase change materials and hydrated inorganic salts, applied in the fields of application, heat exchange materials, chemical instruments and methods, etc., can solve the problems of easy phase separation, low thermal conductivity, large supercooling degree, etc. Effects of separation, large specific surface area, and low degree of subcooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

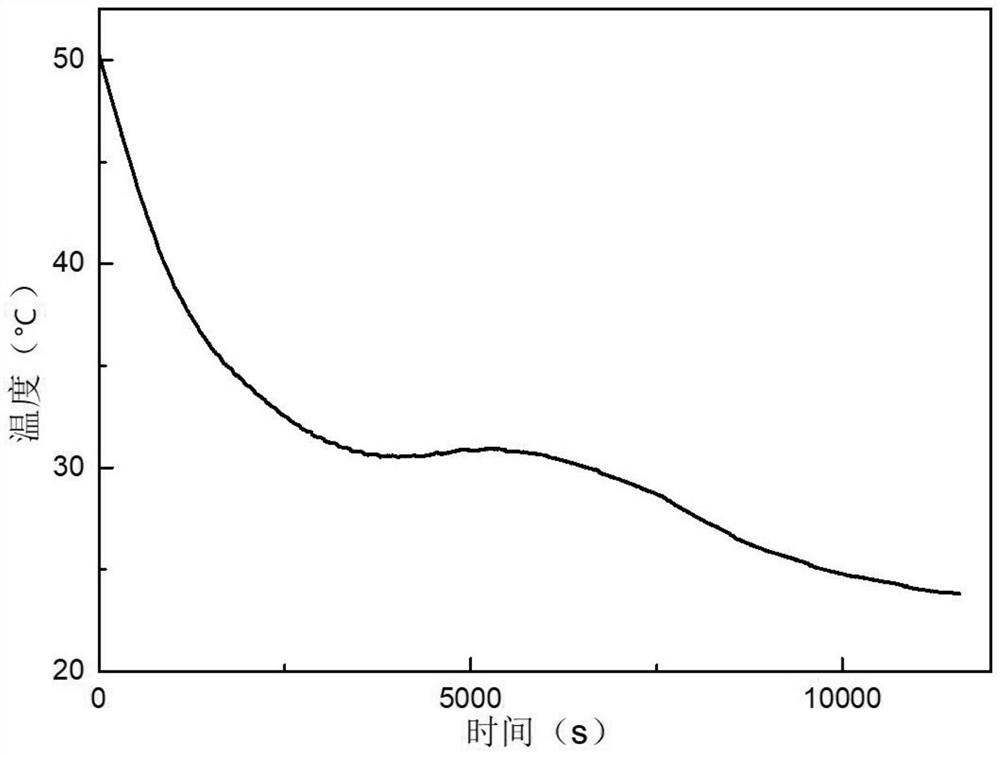

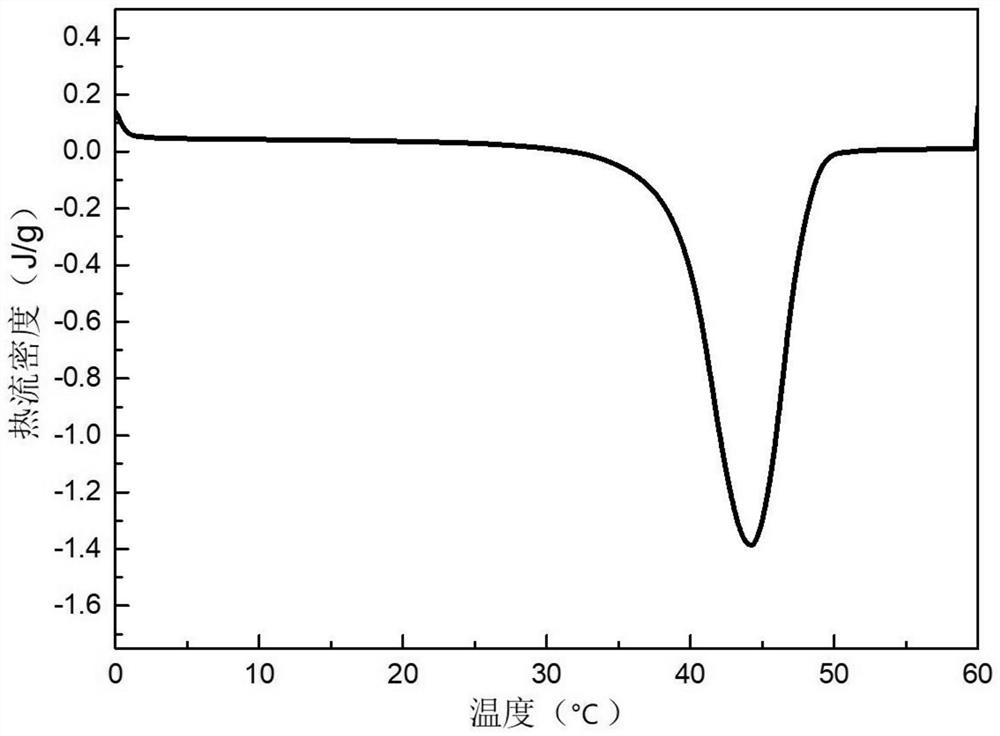

[0038] A modified expanded graphite-hydrated inorganic salt composite phase change material, the preparation method of which comprises the following steps:

[0039] 1) Mix 14g of sodium thiosulfate pentahydrate, 6g of sodium acetate trihydrate, 0.2g of sodium carboxymethylcellulose, 0.04g of sodium pyrophosphate and 0.2g of strontium chloride hexahydrate, and heat in a water bath until Stir at 65°C for 30 minutes, and then sonicate for 15 minutes to obtain a binary hydrated inorganic salt phase change material;

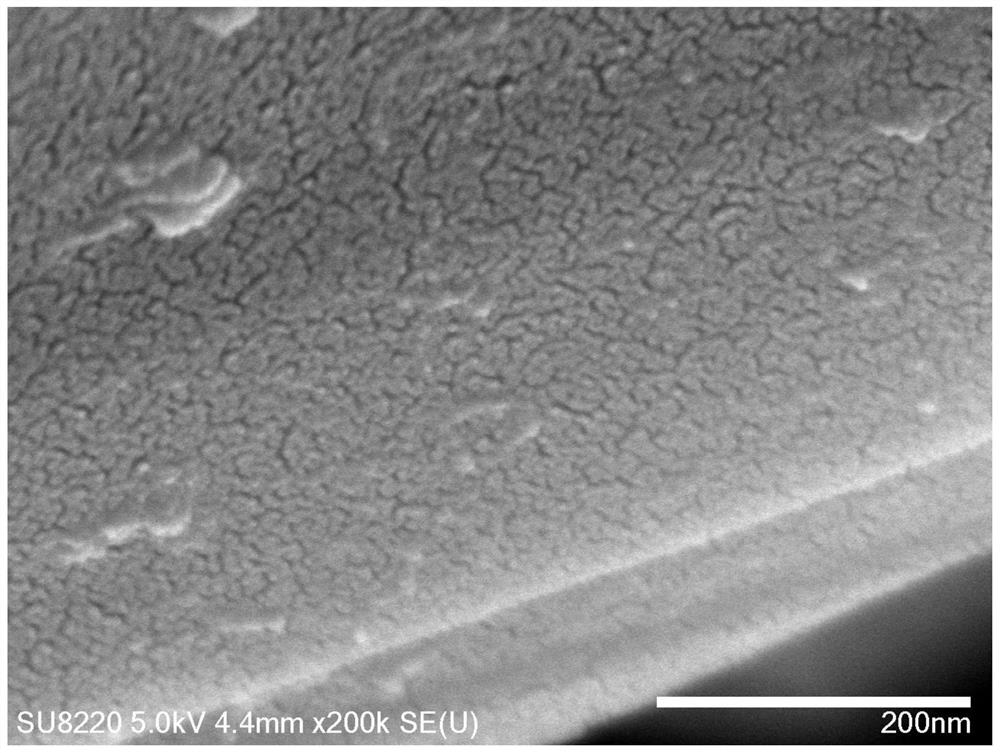

[0040] 2) Disperse 5 g of expanded graphite (diameter 250 μm to 420 μm, volume expansion multiple 200 to 300 times) in 500 mL of ethanol aqueous solution with a mass fraction of 20%, heat it in a water bath to 85 ° C, and then add 30 mL of 0.2 mol concentration dropwise while stirring / L of aluminum nitrate solution and 8mL of ammonia water with a mass fraction of 25% were added dropwise in 15 minutes, reacted for 1 hour after the addition, filtered, and the filtered ...

Embodiment 2

[0052] A modified expanded graphite-hydrated inorganic salt composite phase change material, the preparation method of which comprises the following steps:

[0053] 1) Mix 10g of sodium thiosulfate pentahydrate, 5g of sodium acetate trihydrate, 0.1g of sodium carboxymethylcellulose, 0.02g of sodium pyrophosphate and 0.1g of strontium chloride hexahydrate, and heat in a water bath to Stir at 65°C for 30 minutes, and then sonicate for 15 minutes to obtain a binary hydrated inorganic salt phase change material;

[0054] 2) Disperse 5 g of expanded graphite (diameter 250 μm to 420 μm, volume expansion multiple 200 to 300 times) in 500 mL of ethanol aqueous solution with a mass fraction of 20%, heat it in a water bath to 85 ° C, and then add 30 mL of 0.2 mol concentration dropwise while stirring / L of aluminum nitrate solution and 8mL of ammonia water with a mass fraction of 25% were added dropwise in 15 minutes, reacted for 1 hour after the addition, filtered, and the filtered sol...

Embodiment 3

[0058] A modified expanded graphite-hydrated inorganic salt composite phase change material, the preparation method of which comprises the following steps:

[0059] 1) Mix 15g of sodium thiosulfate pentahydrate, 5g of sodium acetate trihydrate, 0.2g of sodium carboxymethylcellulose, 0.02g of sodium pyrophosphate and 0.2g of strontium chloride hexahydrate, and heat in a water bath to Stir at 65°C for 30 minutes, and then sonicate for 15 minutes to obtain a binary hydrated inorganic salt phase change material;

[0060] 2) Disperse 5 g of expanded graphite (diameter 250 μm to 420 μm, volume expansion multiple 200 to 300 times) in 500 mL of ethanol aqueous solution with a mass fraction of 20%, heat it in a water bath to 85 ° C, and then add 30 mL of 0.2 mol concentration dropwise while stirring / L of aluminum nitrate solution and 8mL of ammonia water with a mass fraction of 25% were added dropwise in 15 minutes, reacted for 1 hour after the addition, filtered, and the filtered sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Peak temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com