Method for obtaining limonite pellets under laboratory conditions

An iron ore ball and laboratory technology, applied in the field of metallurgical research, can solve problems such as limiting the full application ratio of limonite powder and production restrictions, achieve good practicability and economy, improve compressive strength, and strengthen internal consolidation The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

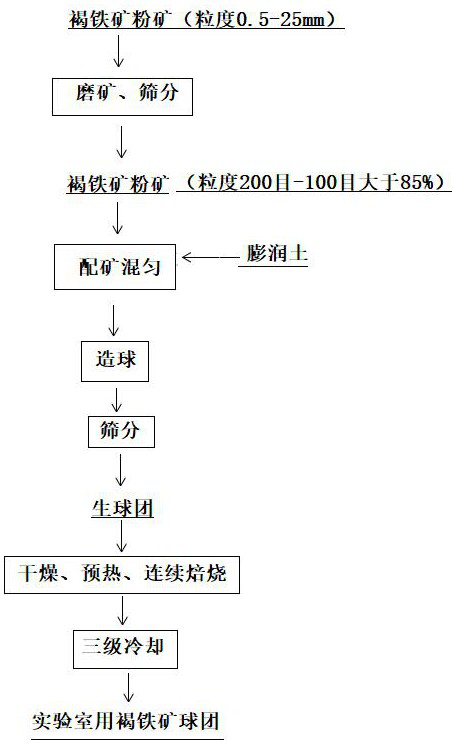

[0021] Such as figure 1 Shown, the method for obtaining limonite pellets under laboratory conditions, it may further comprise the steps:

[0022] Step 1. Add limonite powder with a particle size of 200 mesh to 100 mesh and more than 85% to account for 99% of the total limonite powder content (990g limonite powder), add 1% bentonite (10g bentonite) and mix evenly ore and add water to moisten to obtain 1kg total limonite ore powder;

[0023] Step 2, making the total limonite ore powder obtained in step 1 into green pellets in a pelletizer to obtain green pellets with a diameter of 15 to 35 mm and a content ≥ 95%;

[0024] Step 3. Put the green balls with a diameter of 15-35mm obtained in step 2 into a corundum crucible, dry at 200°C for 20 minutes, heat up to 700°C for preheating for 20 minutes, continue to heat up to 1200°C for 25 minutes, and turn off the electric furnace after roasting. Cool the furnace to 1000°C, then half-open the furnace door and continue to cool down. W...

Embodiment 2

[0028] Such as figure 1 Shown, the method for obtaining limonite pellets under laboratory conditions, it may further comprise the steps:

[0029] Step 1. Add 0.5% bentonite (5g bentonite) to the limonite powder with a particle size of 200 mesh to 100 mesh and more than 85% to account for 99.5% of the total limonite powder content (995g bentonite) and mix evenly ore and add water to moisten to obtain 1kg total limonite ore powder;

[0030] Step 2, making the total limonite ore powder obtained in step 1 into green pellets in a pelletizer to obtain green pellets with a diameter of 15 to 35 mm and a content ≥ 95%;

[0031] Step 3. Put the green balls with a diameter of 15-35mm obtained in step 2 into a corundum crucible, dry at 200°C for 20 minutes, heat up to 700°C for preheating for 20 minutes, continue to heat up to 1200°C for 25 minutes, and turn off the electric furnace after roasting. Cool the furnace to 1000°C, then half-open the furnace door and continue to cool down. Wh...

Embodiment 3

[0035] Such as figure 1 Shown, the method for obtaining limonite pellets under laboratory conditions, it may further comprise the steps:

[0036] Step 1. Add 0.2% bentonite (2g bentonite) to the limonite powder with a particle size of 200 mesh to 100 mesh and more than 85% to account for 99.8% of the total limonite powder content (998g bentonite) and mix evenly ore and add water to moisten to obtain 1kg total limonite ore powder;

[0037] Step 2, making the total limonite ore powder obtained in step 1 into green pellets in a pelletizer to obtain green pellets with a diameter of 15 to 35 mm and a content ≥ 95%;

[0038] Step 3. Put the green balls with a diameter of 15-35mm obtained in step 2 into a corundum crucible, dry at 200°C for 20 minutes, heat up to 700°C for preheating for 20 minutes, continue to heat up to 1200°C for 25 minutes, and turn off the electric furnace after roasting. Cool the furnace to 1000°C, then half-open the furnace door and continue to cool down. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com