Energy-saving system and method for preventing coal economizer from boiling through low-load flue gas diversion

A flue gas diversion and energy-saving system technology, which is applied to steam generation methods, combustion methods, and feedwater heaters using pressure combustion to achieve the effects of improving combustion stability, reducing heat absorption, and reducing ignition heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

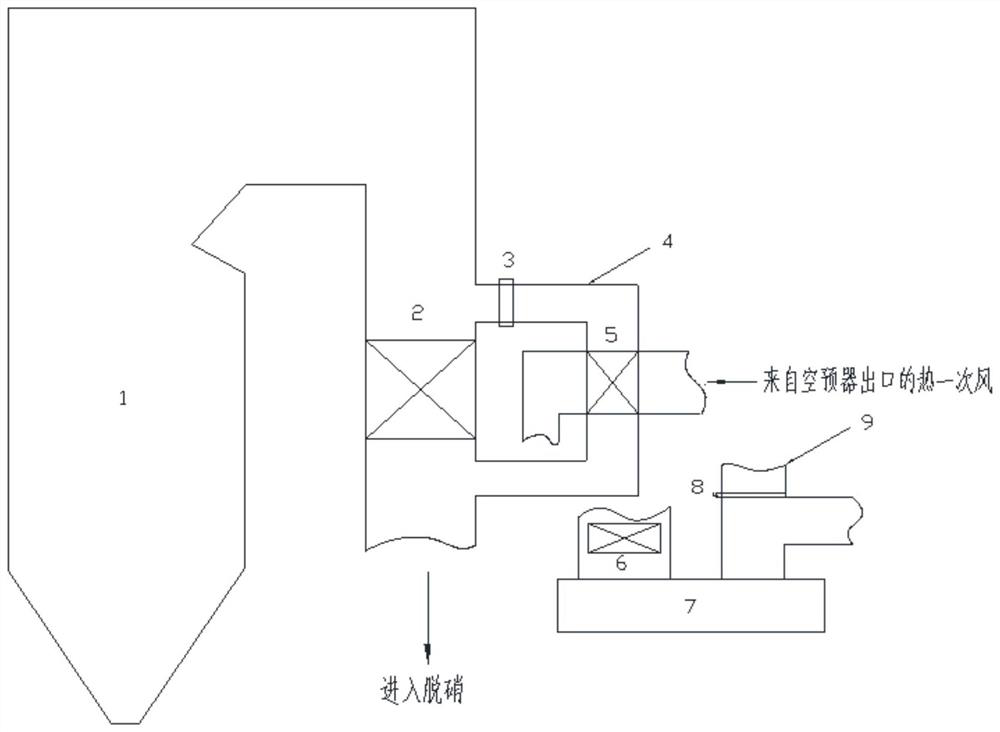

[0021] see figure 1 , a low-load flue gas diversion prevention economizer boiling energy-saving system provided by the present invention includes a boiler 1, a primary economizer 2, a flue gas regulating baffle 3, a diversion flue 4, and a hot primary air heater 5 , Secondary economizer 6, air preheater 7, hot primary air reheating air passage isolation door 8, hot primary air reheating air passage 9.

[0022] Among them, the split flue 4 is arranged side by side next to the main flue of the primary economizer 2, and the hot primary air reheating air duct 9 is arranged side by side next to the main hot air duct.

[0023] When running at low load, open the baffle plate at the entrance of the diverter flue of the economizer to divert part of the flue gas to enter, reduce the amount of flue gas in the main flue, reduce the heat absorption of the economizer, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com