Beef cattle feed preparation assembly line equipment

An assembly line and feed technology, applied in lighting and heating equipment, dry solid materials, animal feeding devices, etc., can solve the problems of large size, inconvenient movement, inability to absorb well, slow recovery of cows, etc., to avoid difficulty in feeding , Improve reprocessing efficiency, avoid the effect of solidification and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

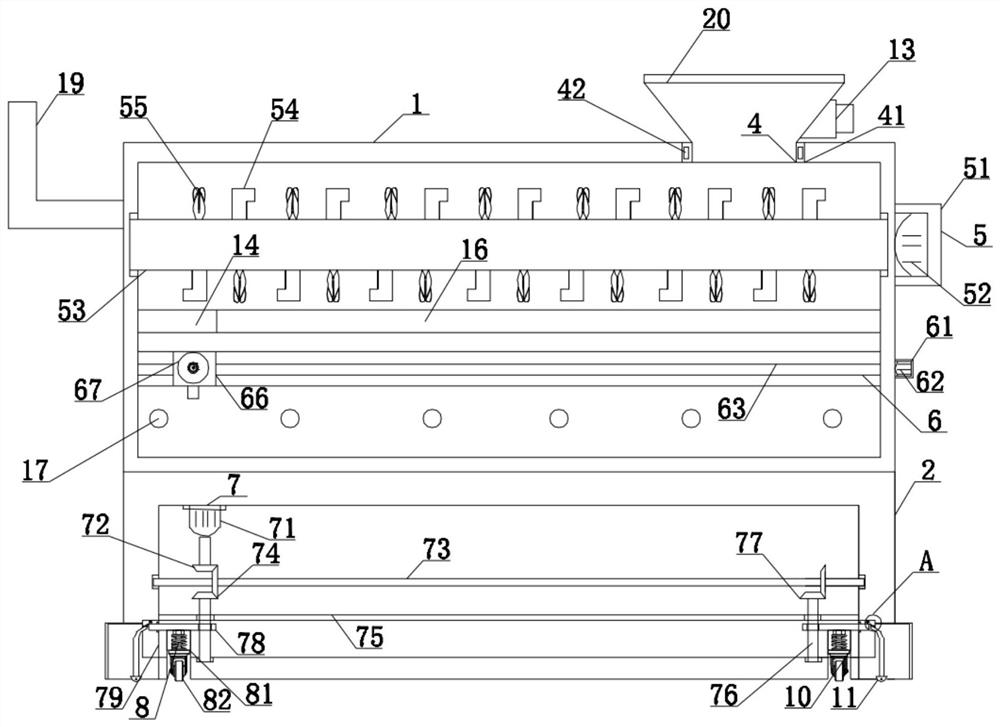

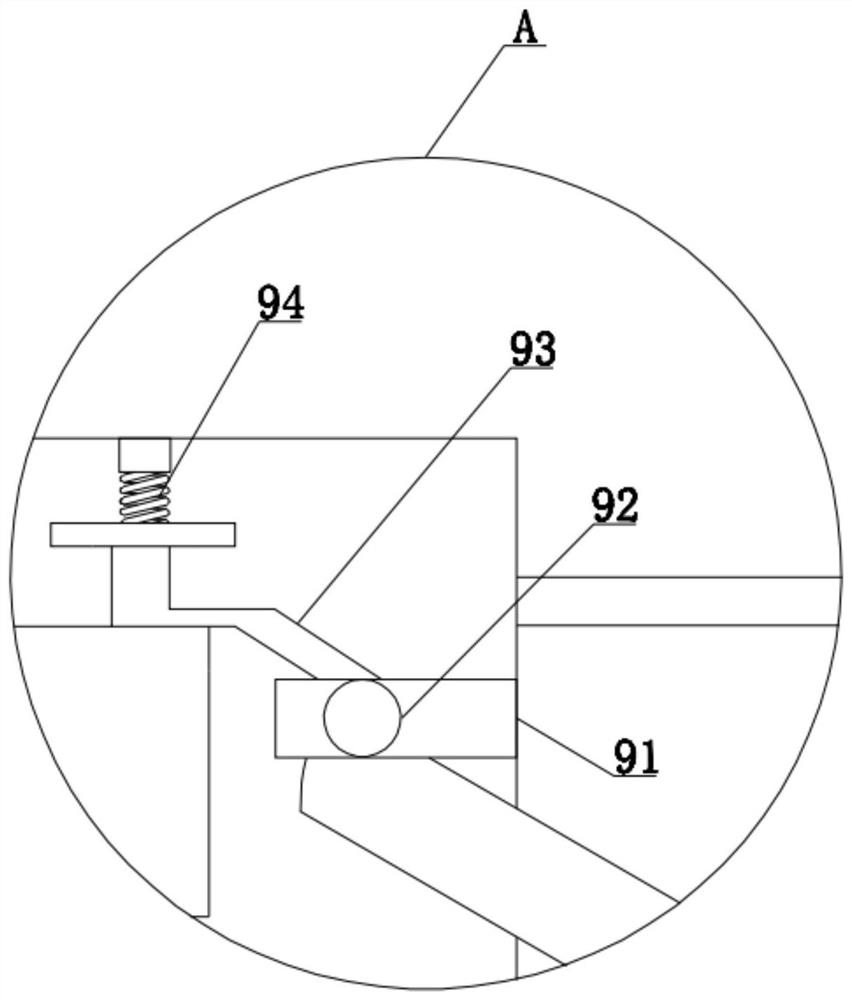

[0035] see Figure 1-5 , a beef cattle feed preparation line equipment, comprising an upper box 1 and a lower box 2, the upper right side of the upper box 1 is fixedly connected with a feeding hopper 20, one side of the feeding hopper 20 is fixedly connected with a connecting pipe 13, It is convenient to connect the feed making unit on the production line through the connecting pipe 13. The right side of the upper end of the upper box 1 is located on the lower side of the feed hopper 20. A sterilizing component 4 is provided, and the inside and right side of the upper box 1 are provided with an anti-freezing component. 5. The inside of the upper box body 1 is fixedly connected with a baffle plate 14, and the inside of the upper box body 1 is fixedly connected with a material guide plate 15. One side of the material guide plate 15 is provided with a material guide hole 16, and the material guide plate 15 is set on the baffle plate. On the lower side of the plate 14, the positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com