Amphoteric surfactant and preparation method and application thereof

A surfactant, amphoteric technology, applied in the field of amphoteric surfactant and its preparation, can solve the problems of poor foam suppression performance and emulsification performance, complicated preparation process and method, and achieve excellent foam suppression performance and emulsification performance. , Low production cost and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In one embodiment of the present invention, a preparation method of the above-mentioned amphoteric surfactant is provided, comprising the following steps:

[0042] 1) prepare reaction intermediate I, the structural formula of described reaction intermediate I is:

[0043] C 18 H 37 NH(CH 2 ) 3 NHCH 2 CH 2 CONHC(CH 3 ) 2 CH 2 SO 3 H;

[0044] 2) chloroacetic acid and sodium hydroxide are reacted to prepare sodium chloroacetate aqueous solution;

[0045] 3) Add the aqueous sodium chloroacetate solution dropwise to the reaction intermediate I, and mix and react to obtain an amphoteric surfactant.

[0046] In a specific embodiment, in step 1), the preparation of reaction intermediate I includes the following steps: N-hydrogenated tallow-1,3-propylenediamine, alcohol solvent and 2-acrylamide-2- Methylpropanesulfonic acid (abbreviated as AMPS) mixed reaction;

[0047] In a specific embodiment, in step 2), preparing an aqueous sodium chloroacetate solution include...

Embodiment 1

[0065] The present embodiment provides a preparation method of an amphoteric surfactant, comprising the following steps:

[0066] (1) Preparation of amphoteric surfactant:

[0067] 1) 326.0 g of N-hydrogenated tallow-1,3-propylene diamine and 500 g of isopropanol were added to the reactor, and the mixture was heated and stirred to dissolve. Then 215.6 g of AMPS was gradually added, and the reaction was stirred at 75° C. for 4 h to obtain the reaction intermediate I.

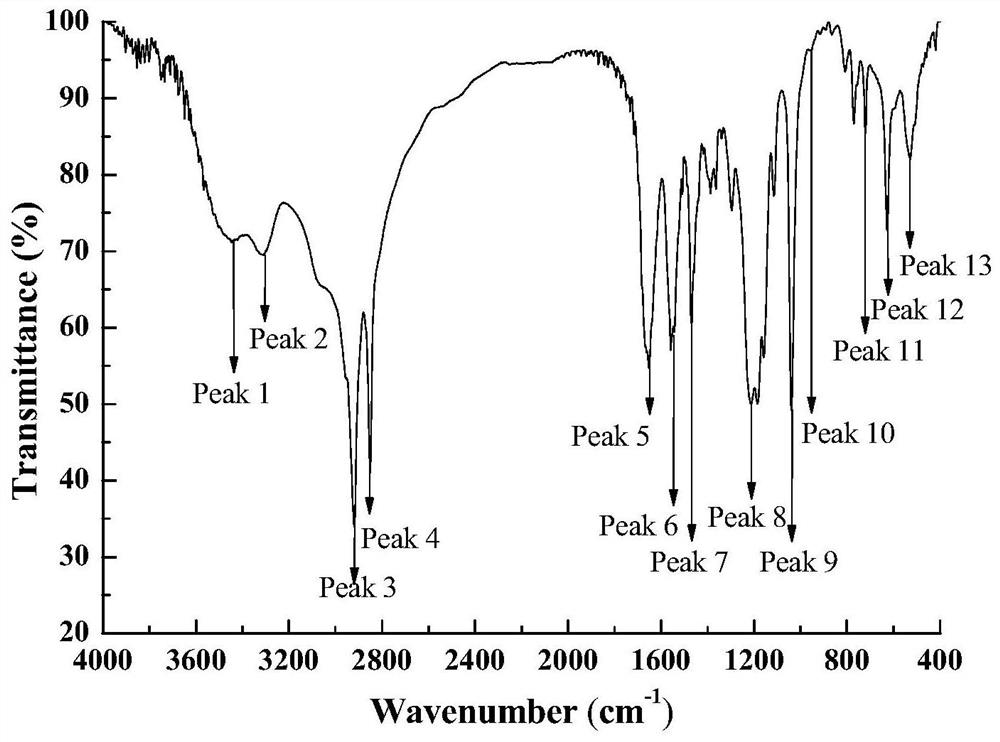

[0068] Above-mentioned synthetic product carries out FTIR detection after adopting ethyl acetate as solvent to carry out recrystallization separation and purification, and the results are as follows (see figure 1 ): 3439cm -1 (peak 1) is the stretching vibration peak of O-H in the sulfonic acid group, 3308 cm -1 (peak 2) is the N-H stretching vibration peak of secondary amide, 2924cm -1 (peak 3) is the asymmetric stretching vibration absorption peak of methylene, 2855cm -1 (peak4) is the peak of symmetrical ...

Embodiment 2

[0082] The present embodiment provides a preparation method of an amphoteric surfactant, comprising the following steps:

[0083] (1) Preparation of amphoteric surfactant:

[0084] 1) 326.0 g of N-hydrogenated tallow-1,3-propylene diamine and 500 g of isopropanol were added to the reactor, and the mixture was heated and stirred to dissolve. Then 215.6 g of AMPS was gradually added, and the reaction was stirred at 75° C. for 4 h to obtain the reaction intermediate I.

[0085] 2) Prepare aqueous sodium chloroacetate solution: dissolve 198.4 g of chloroacetic acid in 400 g of water to obtain an aqueous chloroacetic acid solution, dissolve 84.0 g of sodium hydroxide in 160 g of water to obtain an aqueous solution of sodium hydroxide, and gradually add the aqueous sodium hydroxide solution to the aqueous chloroacetic acid solution , and reacted at 25 °C for 10 min to obtain an aqueous solution of sodium chloroacetate.

[0086] 3) The aqueous sodium chloroacetate solution was grad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com