High-performance cement and preparation method thereof

A high-performance, cement technology, applied in the field of cement preparation, can solve the problems of insufficient bonding strength, compressive strength and flexural strength of decorative cement, avoid cracking and shedding, improve strength, good corrosion resistance and construction performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

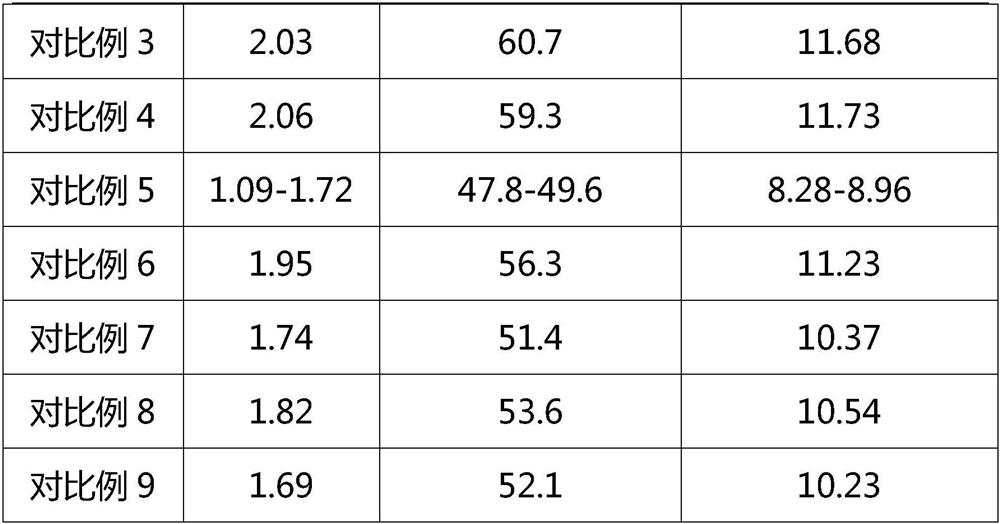

Examples

Embodiment 1

[0031] A high-performance cement, in parts by weight, comprising the following raw materials: 55 parts of Portland cement, 3 parts of expansion agent, 7 parts of metakaolin, 4 parts of silica fume, 2 parts of whiskers, and 7.5 parts of redispersible latex powder 1.5 parts of water reducer, 0.7 parts of defoamer, 0.12 parts of cellulose ether, 17.5 parts of heavy calcium, 9 parts of reduced iron, 3 parts of vinyl acetate copolymer wax, and 5 parts of barium chromate.

[0032] The Portland cement is ordinary Portland 42.5 cement; the expansion agent is a sulphoaluminate expansion agent.

[0033] The whiskers are calcium sulfate whiskers with an average diameter of 2 μm and an average length of 34 μm.

[0034] The redispersible latex powder is a redispersible latex powder with a glass transition temperature of -2 to 3°C.

[0035] The water reducer is a powdery polycarboxylate water reducer; the defoamer is a powdery polyether defoamer; the cellulose ether is hydroxypropylmethylc...

Embodiment 2

[0039] A high-performance cement, in parts by weight, comprising the following raw materials: 60 parts of Portland cement, 2 parts of expansion agent, 10 parts of metakaolin, 2 parts of silica fume, 3 parts of whiskers, 5 parts of redispersible latex powder 2 parts, water reducer 2 parts, defoamer 0.3 parts, cellulose ether 0.15 parts, heavy calcium 15 parts, reduced iron 10 parts, vinyl acetate copolymer wax 2 parts, barium chromate 6 parts.

[0040] The Portland cement is ordinary Portland 52.5 cement; the expansion agent is a sulphoaluminate expansion agent.

[0041] The whiskers are calcium sulfate whiskers with an average diameter of 6 μm and an average length of 95 μm.

[0042] The redispersible latex powder is a redispersible latex powder with a glass transition temperature of -1 to 2°C.

[0043] The water reducer is a powdery polycarboxylate water reducer; the defoamer is a powdery polyether defoamer; the cellulose ether is hydroxypropylmethylcellulose with a viscosit...

Embodiment 3

[0047] A high-performance cement, in parts by weight, comprising the following raw materials: 45 parts of Portland cement, 4 parts of expansion agent, 4 parts of metakaolin, 6 parts of silica fume, 1 part of whiskers, and 10 parts of redispersible latex powder 1 part of water reducer, 1.0 part of defoamer, 0.1 part of cellulose ether, 20 parts of heavy calcium, 6 parts of reduced iron, 4 parts of vinyl acetate copolymer wax, and 4 parts of barium chromate.

[0048] The Portland cement is high-magnesium low-heat cement; the expansion agent is a sulphoaluminate expansion agent.

[0049] The whiskers are calcium sulfate whiskers with an average diameter of 7 μm and an average length of 200 μm.

[0050] The redispersible latex powder is a redispersible latex powder with a glass transition temperature of -3 to 3°C.

[0051] The water reducer is a naphthalene-based high-efficiency water reducer; the defoamer is a powdery polyether defoamer; the cellulose ether is hydroxypropylmethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com