Supported polyoxometallate material for preparing aniline through nitrobenzene hydrogenation

A polyoxometalate and supported technology, which is applied in the preparation of amino compounds, organic compounds, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of high energy consumption of catalysts, and achieve simple preparation methods , high conversion rate and mild catalytic reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

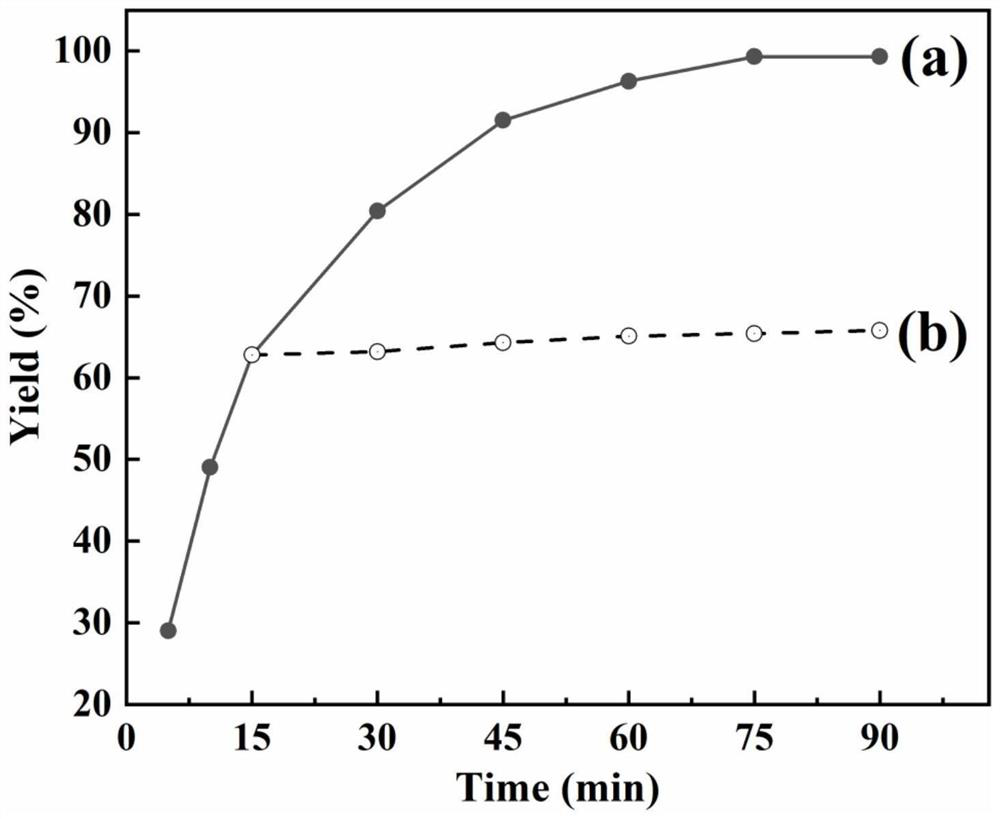

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0031] Preparation of a supported polyoxometalate material for the hydrogenation of nitrobenzene to aniline:

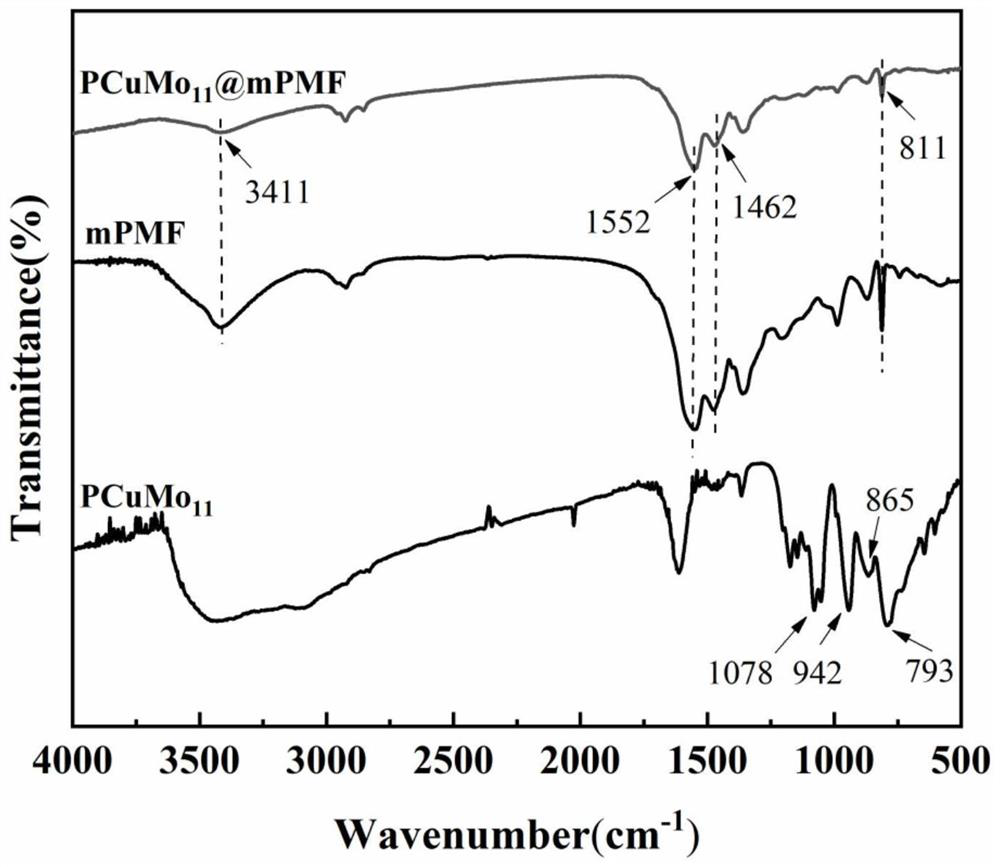

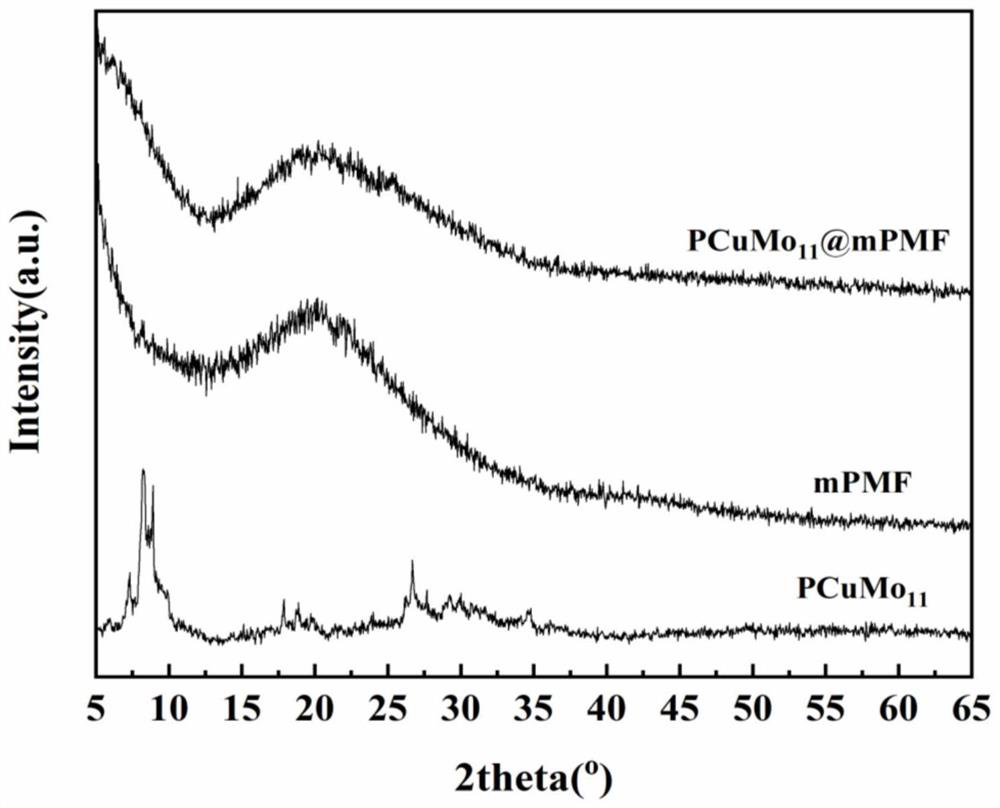

[0032](1) Preparation of nitrogen-rich covalent organic porous material mPMF: Add melamine (5.4mmol), paraformaldehyde (3mmol) and 5mL dry dimethyl sulfoxide into the reactor, heat at 120°C for 1h, take it out, Cooled to room temperature, stirred by magnetic force for 30 minutes, put it into the oven again, and reacted at 160°C for 48 hours. The obtained solid was washed and filtered with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com