Beneficiation method for separating arsenopyrite from high-arsenic gold concentrate

A beneficiation method and gold concentrate technology are applied in the field of separation of poisonous sand from low-grade refractory arsenic-containing gold concentrate, and can solve the problems of unsatisfactory arsenopyrite separation efficiency, high equipment and environmental protection requirements, and difficult management. The phenomenon of reaching the flotation end point is obvious, the comprehensive recovery value is improved, and the operability is strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

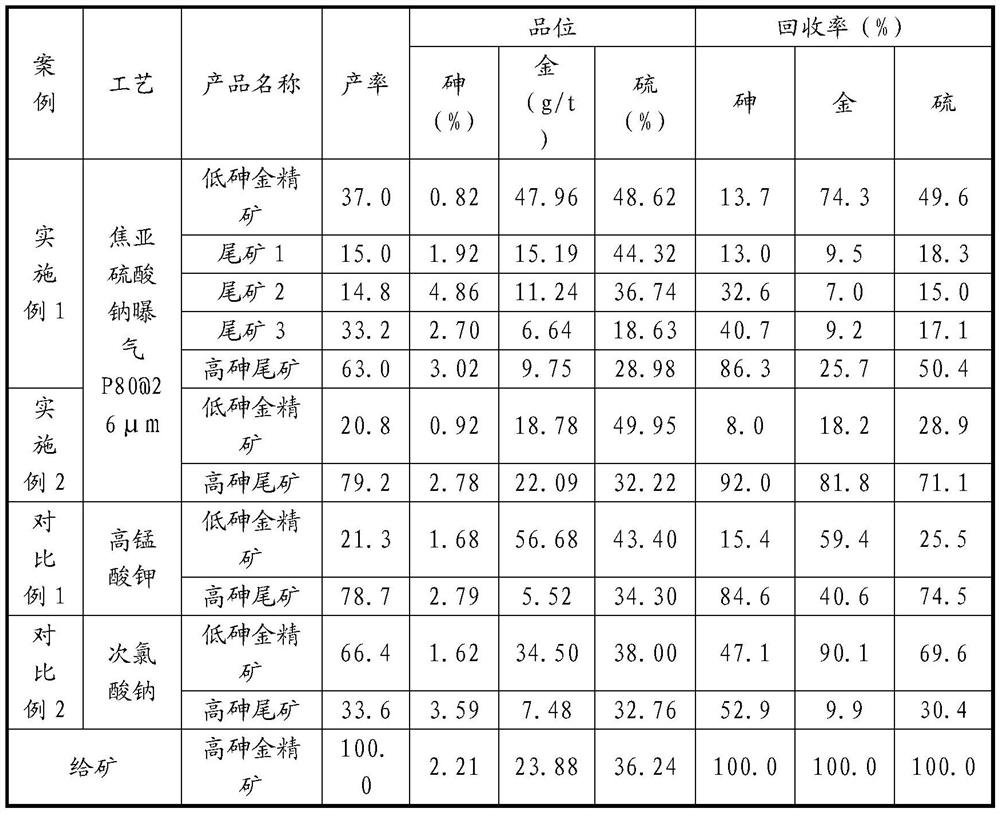

[0030] This example selects the test sample from a gold concentrate produced by a dressing plant in Gansu, the fineness is P80@49μm (-0.074mm accounts for 91%), the moisture content of the concentrate is 8%, contains a large amount of residual chemicals, and the gold mine contains 23.88g / t, containing 2.21% arsenic and 36.24% sulfur, belongs to low-grade refractory high-arsenic gold concentrate. The main metal minerals in the ore are pyrite and arsenopyrite, a small amount of gold minerals exist as monomers, pyrite and gold are closely connected, and the gangue minerals are mainly quartz.

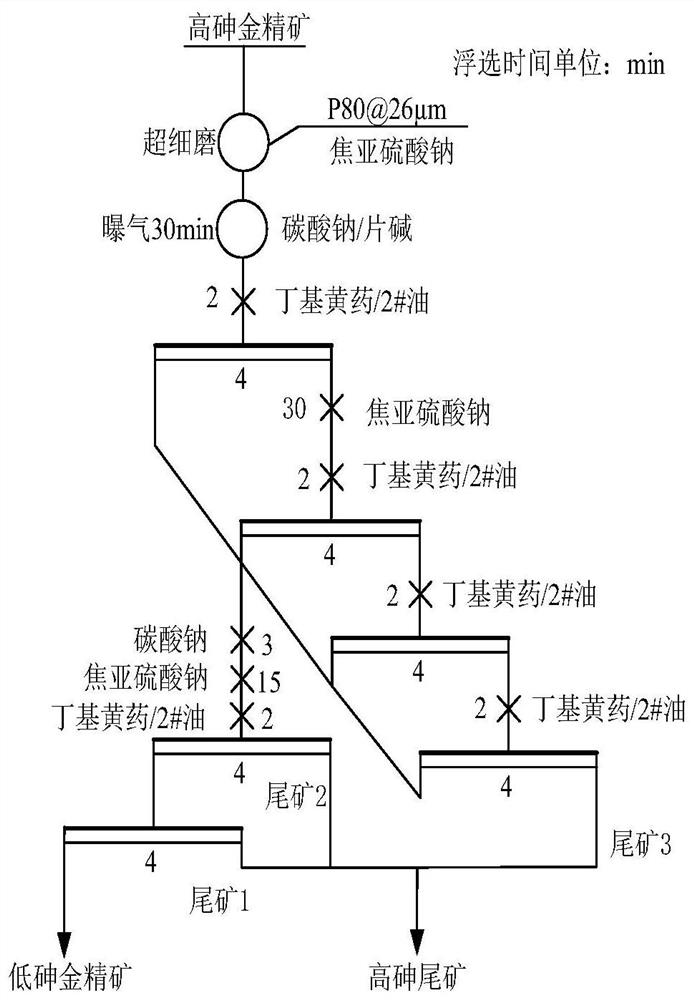

[0031] In this example, a beneficiation method for separating arsenopyrite from high-arsenic gold concentrates is used to treat the above-mentioned test samples. Gas oxidation, and finally through the "four times of roughing, two times of beneficiation" operation to obtain high arsenic gold concentrate and low arsenic gold concentrate. Such as figure 1 As shown, it specifically includes ...

Embodiment 2

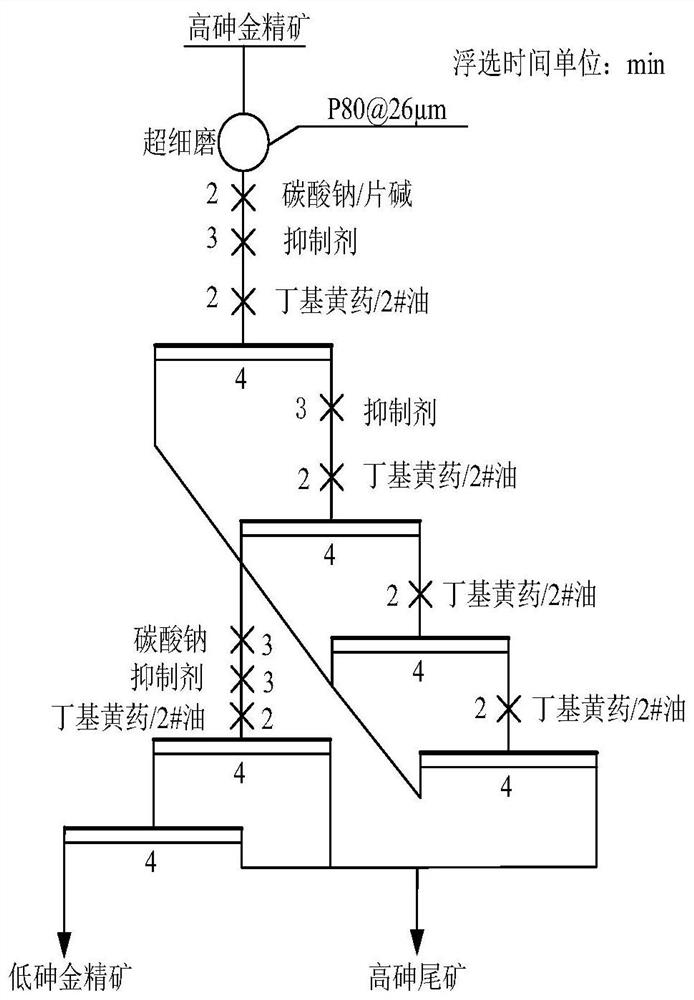

[0039]This example uses the same steps as Example 1 to process the same ore. The main difference is that the pulp aeration and oxidation operation is 10 minutes; the initial redox potential Eh of the roughing operation is about -15mV. Stir the agent for 5 minutes; add 500g / t sodium carbonate in the selection I operation to stabilize the pH value of the ore pulp at about 8.0, and add 500g / t of sodium metabisulfite in the selection I operation to control the oxidation-reduction potential Eh=5mV Left and right, the added butyl xanthate is pyrite and gold collector.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com