Preparation method of triethylene glycol di-n-octoate

A technology of triethylene glycol and n-octanoate, which is applied in the field of ester plasticizers, can solve the problems of harshness, high production cost, and complicated preparation conditions, and achieve the effects of low cost, reduced production cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

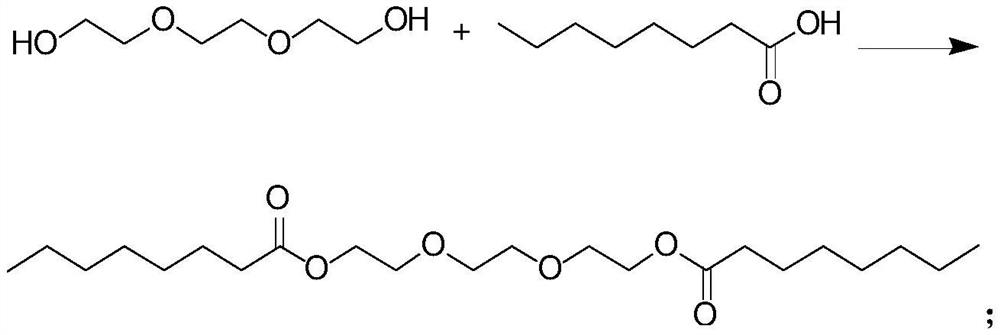

[0027] The present embodiment provides a kind of preparation method of triethylene glycol di-n-octanoate, comprising the following steps:

[0028] S1: In a heated 10m equipped with stirrer, internal thermometer and water separator 3 In the reaction pot, charge triethylene glycol, n-octanoic acid with an excess of 20 mol% based on the hydroxyl group to be esterified, and tetraisobutyl titanate accounting for 0.04 mol% of the molar amount of triethylene glycol, start stirring, then turn on condensed water and Heating to make it react at 125°C, and removing the formed reaction water on the oil-water separator, and continuously weighing the reaction water discharged from the oil-water separator until no more reaction water is generated, then the reaction is terminated;

[0029] S2: Move the reaction materials into the distillation kettle, and at the same time turn on the vacuum pump unit to carry out vacuum distillation to remove n-octanoic acid, collect the condensate when the va...

Embodiment 2

[0034] The present embodiment provides a kind of preparation method of triethylene glycol di-n-octanoate, comprising the following steps:

[0035] S1: In a heated 10m equipped with stirrer, internal thermometer and water separator 3 In a 1-liter reaction pot, put triethylene glycol, n-octanoic acid with an excess of 30 mol% based on the hydroxyl group to be esterified, and tetraisobutyl titanate accounting for 0.02 mol% of the molar amount of triethylene glycol, start stirring, and then turn on the condensate and heating to make it react at 120°C, and remove the formed reaction water on the oil-water separator, and continuously weigh the reaction water discharged from the oil-water separator until no more reaction water is generated, then end the reaction;

[0036] S2: Move the reaction materials into the distillation kettle, and at the same time turn on the vacuum pump unit to carry out vacuum distillation to remove n-octanoic acid, collect the condensate when the vacuum degr...

Embodiment 3

[0039] The present embodiment provides a kind of preparation method of triethylene glycol di-n-octanoate, comprising the following steps:

[0040] S1: In a heated 10m equipped with stirrer, internal thermometer and water separator 3In the reaction pot, charge triethylene glycol, n-octanoic acid with an excess of 25 mol% based on the hydroxyl group to be esterified, and tetrabutyl titanate accounting for 0.03 mol% of the molar amount of triethylene glycol, start stirring, then turn on condensed water and heating , making it react at 130°C, and removing the formed reaction water on the oil-water separator, and continuously weighing the reaction water discharged through the oil-water separator until no more reaction water is generated, the reaction is terminated;

[0041] S2: Move the reaction materials into the distillation kettle, and at the same time turn on the vacuum pump unit to carry out vacuum distillation to remove n-octanoic acid, collect the condensate when the vacuum ...

PUM

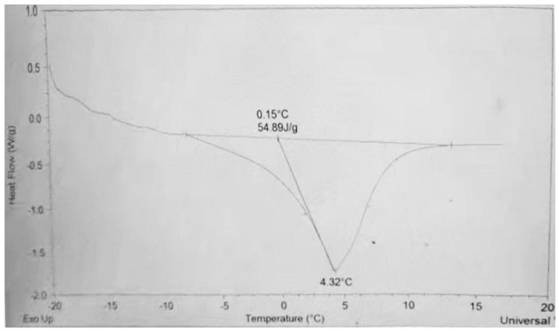

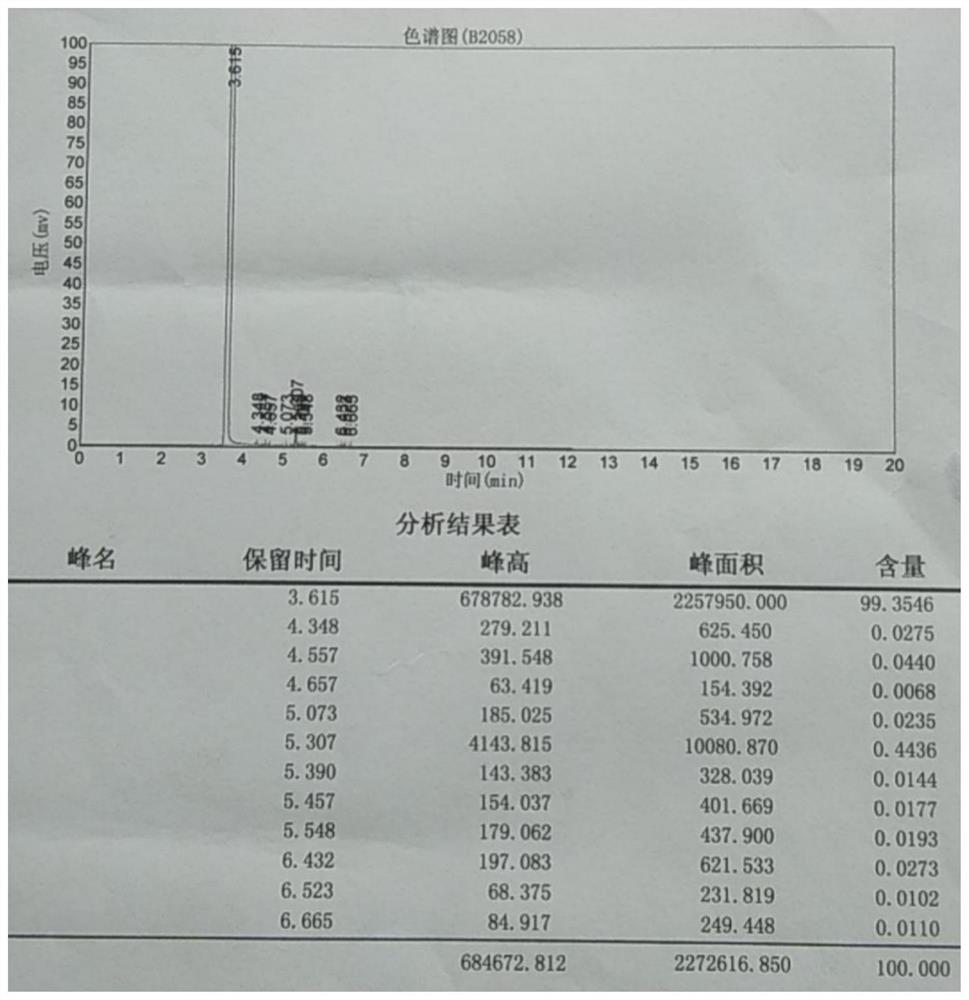

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com