Composite material and preparation method thereof and quantum dot light-emitting diode

A technology of quantum dot luminescence and composite materials, applied in the field of luminescence display, to achieve the effect of improving luminescence performance, improving carrier transport performance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

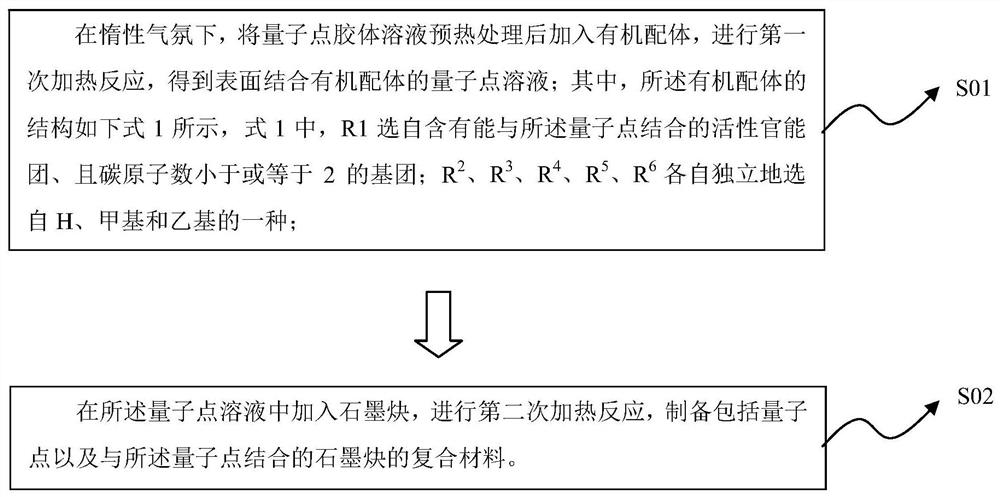

[0040] combine figure 1 , the second aspect of the embodiment of the present application provides a preparation method of a composite material, comprising the following steps:

[0041] S01. Under an inert atmosphere, add organic ligands after preheating the quantum dot colloid solution, and carry out the first heating reaction to obtain a quantum dot solution with organic ligands bound on the surface; wherein, the structure of the organic ligand is as shown in formula 1 below shown, in Equation 1, R 1 R 2 , R 3 , R 4 , R 5 , R 6 each independently selected from one of H, methyl and ethyl;

[0042]

[0043] S02. adding graphdiyne into the quantum dot solution, and performing a second heating reaction to prepare a composite material comprising quantum dots and graphdiyne combined with quantum dots.

[0044] In the preparation method of the composite material provided in the embodiment of the present application, the quantum dot colloid solution is preheated and then or...

Embodiment 1

[0088] A preparation method of composite material, comprising the following steps:

[0089] An appropriate amount of CdS / ZnS was added to 20 ml of ODE to form a quantum dot colloid solution with a total concentration of 20 mg / mL. Subsequently, the temperature was raised to 200° C. in an argon atmosphere, and then benzyl mercaptan was injected according to the volume ratio of quantum dots to benzyl mercaptan 50:1, and the reaction was incubated for 30 min to form a quantum dot solution.

[0090] According to the molar ratio of quantum dots to graphdiyne of 1:0.1, an appropriate amount of graphdiyne was added to the quantum dot solution, and the solution was continued to stir at 200 °C for 30 min. After the reaction, after the reaction solution was lowered to room temperature, it was precipitated and washed with ethyl acetate, ethanol, acetone and ethanol in steps, and then re-dispersed in n-hexane to prepare a graphyne-CdS / ZnS quantum dot composite material.

Embodiment 2

[0092] A preparation method of composite material, comprising the following steps:

[0093] Put an appropriate amount of Cd 1-x Zn x S was added to 20 ml of 1-hexadecene to form a quantum dot colloid solution with a total concentration of 30 mg / mL. Subsequently, the temperature was raised to 200° C. in an argon atmosphere, and then benzyl mercaptan was injected according to the volume ratio of quantum dots to benzyl mercaptan 40:1, and the reaction was kept for 30 min to form a quantum dot solution.

[0094] According to the molar ratio of quantum dots to graphdiyne of 1:0.2, an appropriate amount of graphdiyne was added to the quantum dot solution, and the solution was continued to stir at 200 °C for 1 h. After the reaction, after the reaction solution was lowered to room temperature, it was precipitated and washed with ethyl acetate, ethanol, acetone and ethanol step by step, and then redispersed in n-octane to prepare graphyne-Cd 1-x Zn x S quantum dot composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hole mobility | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com