a ni-based 3 (hhtp) 2 Conductive thin film field effect transistor and its preparation method

A technology of field effect transistors and conductive thin films, applied in field effect transistors based on Ni32 conductive thin films and its preparation field, can solve the problem of poor contact between conductive thin films and device substrates and source and drain electrodes, poor uniformity of conductive thin films, heavy preparation Poor performance and other problems, to achieve the effect of improved carrier transport performance, good repeatability, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

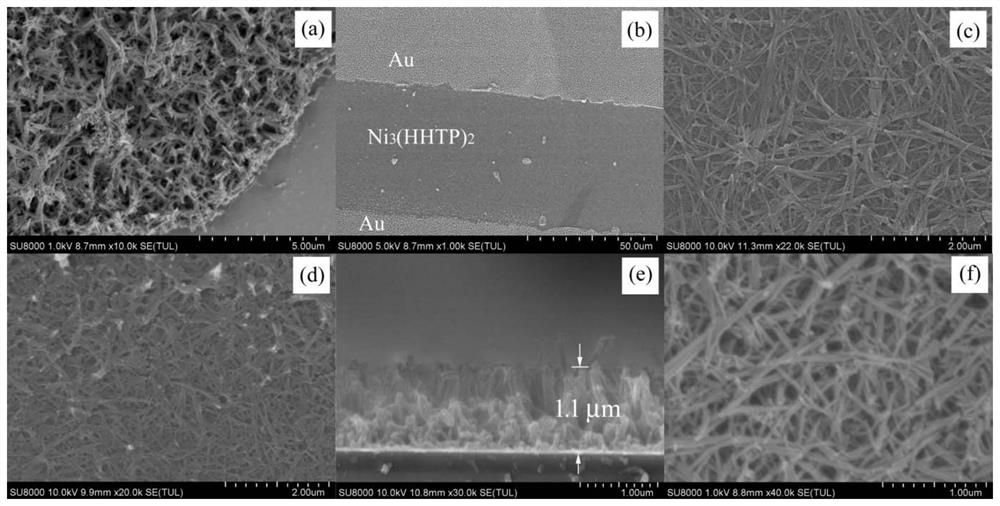

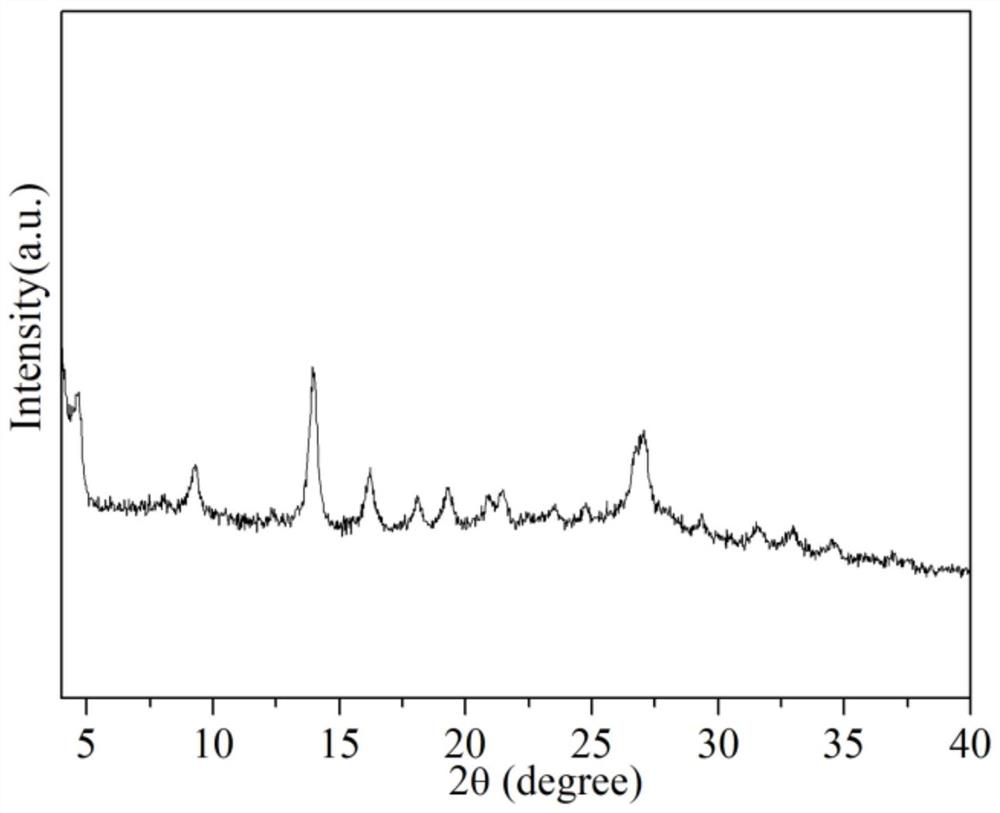

[0035] The invention provides a Ni 3 (HHTP) 2 The preparation method of conductive film can comprise the following steps:

[0036] Step 1. Adjust the pH value of the nickel acetate solution to 7.5-8.0, then add the hexahydroxytriphenylene ligand solution, and mix and stir (for example: it can be mixed and stirred for 3-8 minutes), so as to prepare Ni 3 (HHTP) 2 Reaction precursor.

[0037] Step 2, the substrate (the substrate can be a silicon wafer substrate in the prior art, a silicon dioxide / silicon substrate (the silicon dioxide / silicon substrate refers to a substrate on which a layer of silicon dioxide is grown on the surface of a silicon wafer), Field effect transistor substrates including source, drain, gate three-terminal electrodes and channels, etc.) soak in nickel acetate solution with a concentration of 3.5 to 4.0 mg / mL for 3 to 5 minutes, and then take it out to dry (for example: it can be dried naturally or blown dry), and then suspend the dried substrate in t...

Embodiment 1

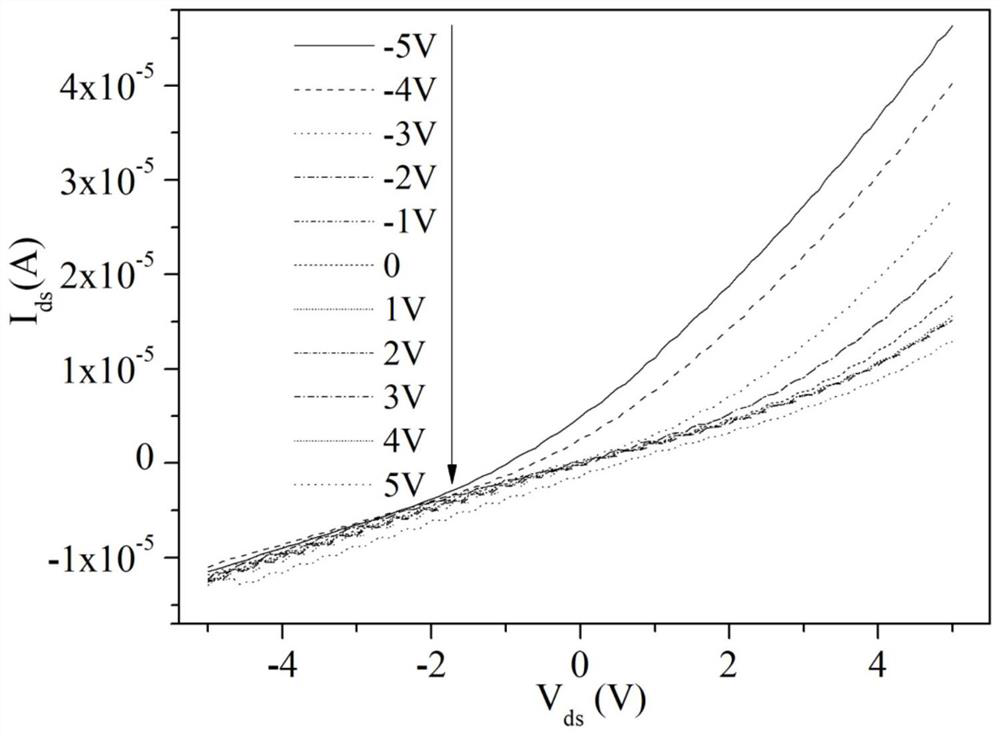

[0064] A Ni-based 3 (HHTP) 2 The field-effect transistor of conductive thin film, its preparation method comprises the following steps:

[0065] Step a1, select a silicon wafer with a silicon dioxide thickness of 280-300nm, soak it with ethanol and deionized water for ultrasound respectively, then spin-coat BP212-37S photoresist on the surface of the silicon wafer, pre-baked, and perform ultraviolet light according to the mask Engraving, development, post-baking after blowing dry with nitrogen, and then using magnetron sputtering to deposit an 80nm thick gold electrode layer on the silicon substrate, the channel length between the source and drain ends is 50 μm, and the width is 2000 μm; finally Soak ultrasonic waves in acetone for 40s, rinse and clean the surface of the device with ethanol and water, so as to prepare a field effect transistor substrate including source, drain, gate three-terminal electrodes and a channel.

[0066] Step a2, 30mg of nickel acetate tetrahydrat...

Embodiment 2

[0069] A Ni-based 3 (HHTP) 2 The field-effect transistor of conductive thin film, its preparation method comprises the following steps:

[0070] Step b1, select a silicon wafer with a silicon dioxide thickness of 280-300nm, soak it with ethanol and deionized water for ultrasound respectively, then spin-coat BP212-37S photoresist on the surface of the silicon wafer, pre-baked, and perform ultraviolet light according to the mask Engraving, development, post-baking after blowing dry with nitrogen, and then using magnetron sputtering to deposit an 80nm thick gold electrode layer on the silicon substrate, the channel length between the source and drain ends is 50 μm, and the width is 2000 μm; finally Soak ultrasonic waves in acetone for 40s, rinse and clean the surface of the device with ethanol and water, so as to prepare a field effect transistor substrate including source, drain, gate three-terminal electrodes and a channel.

[0071] Step b2, 30mg of nickel acetate tetrahydrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com