Coke oven top structure capable of realizing smokeless coaling

A furnace top structure and smokeless coal charging technology, which is applied in coking ovens, coking oven heating, coking oven parts, etc., can solve the problem of smoke and dust escape, without reducing waste gas and smoke emissions, and the circulation of coal charging holes on the furnace roof The space cannot meet the pressure requirements of the top of the furnace, etc., so as to avoid direct discharge from polluting the environment and reduce pollution discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

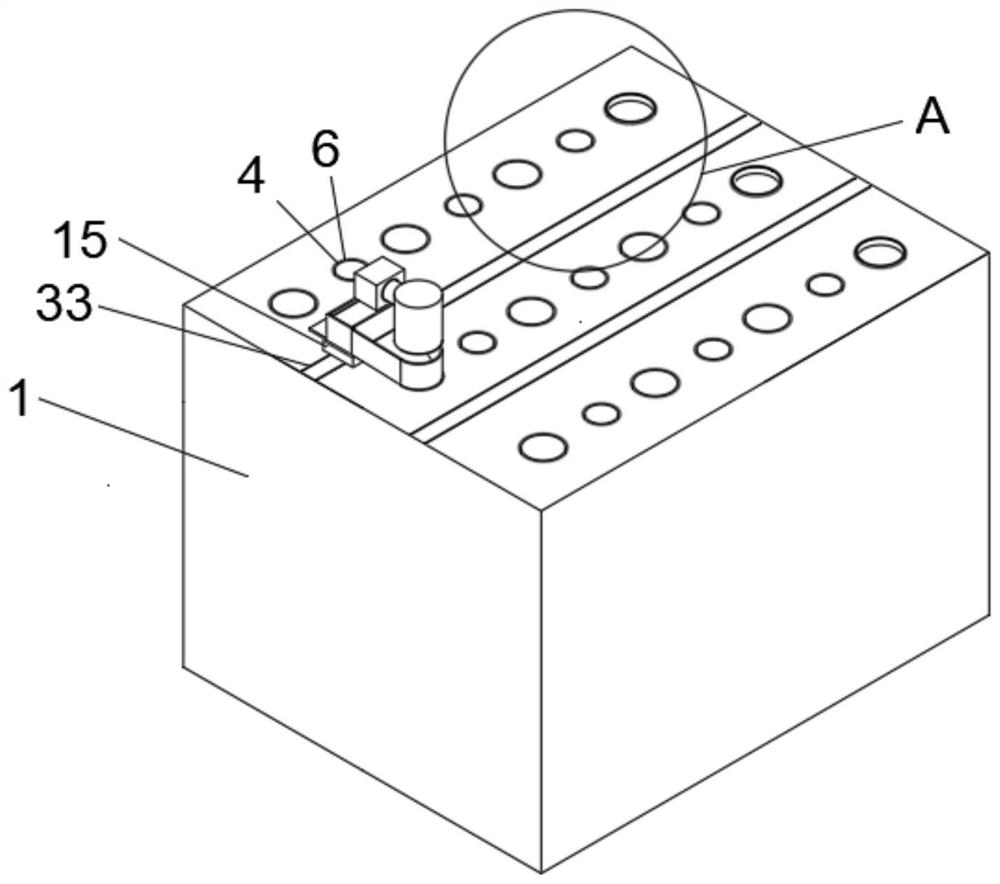

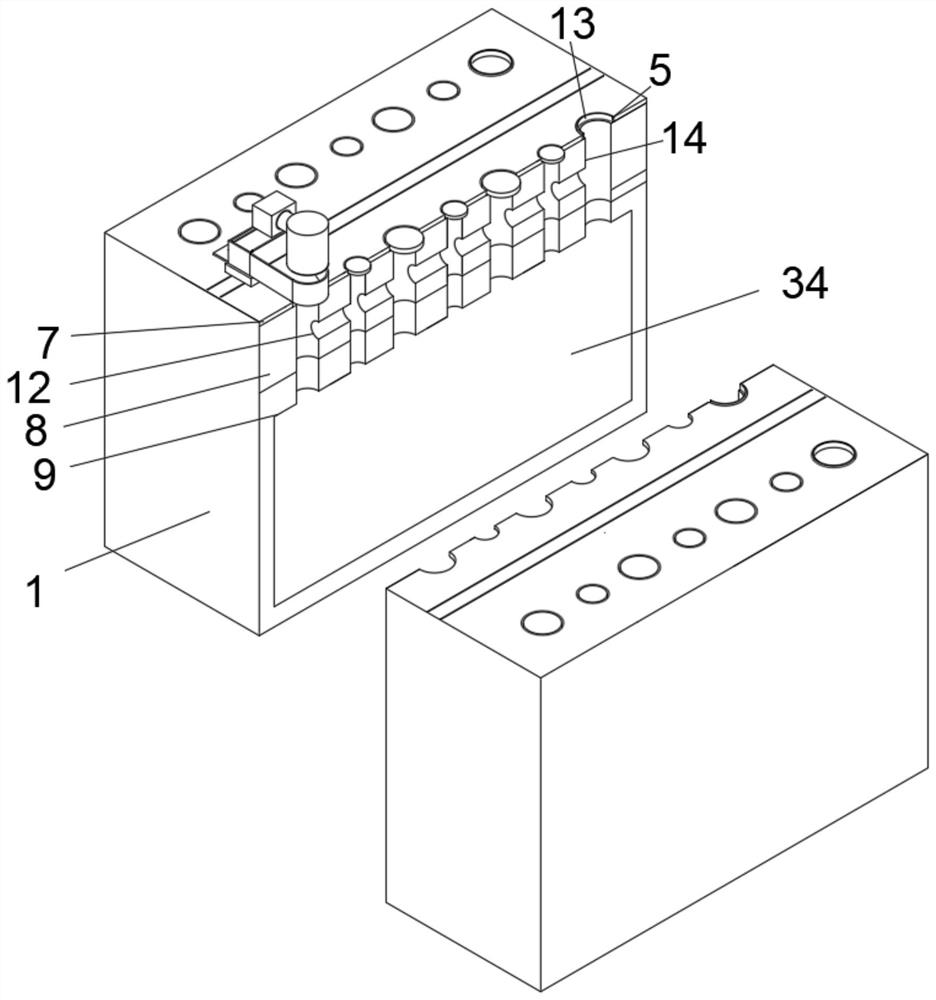

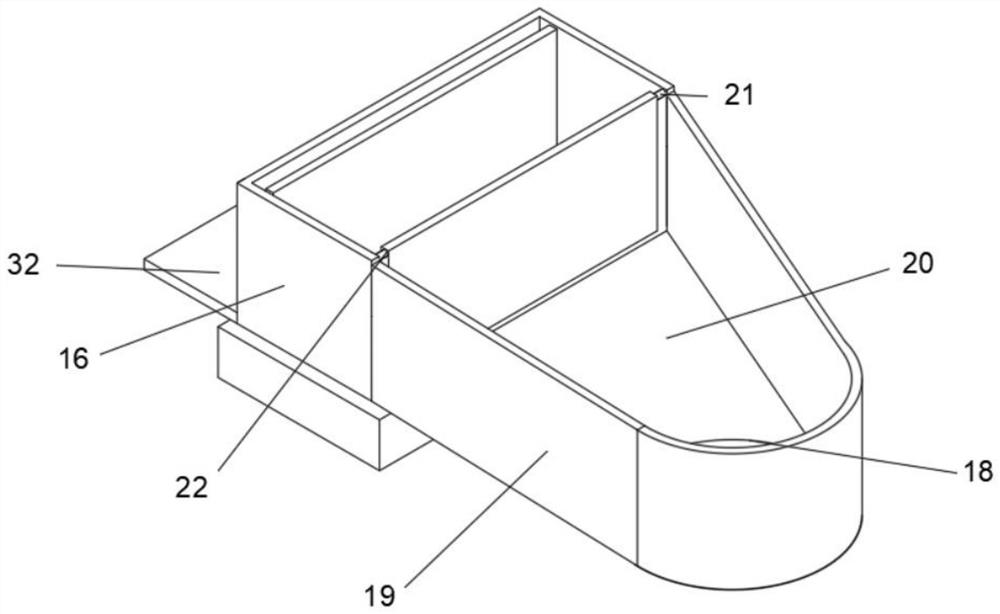

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , a coke oven roof structure for realizing anthracite coal charging proposed by the present invention, comprising a coke oven body 1, the top surface of the coke oven body 1 is provided with several fixing grooves A2, and the inner bottom surface of the fixing groove A2 is provided with The coal charging hole 10, several fixing grooves C5 are all set on the top surface of the coke oven body 1, the rising pipe 13 is fixedly installed on the bottom surface of the fixing groove C5, and several fixing grooves B4 are all fixedly set on the top surface of the coke oven body 1, The inner bottom surface of the fixed tank B4 is provided with a fire viewing hole 11, and several rails 33 are fixed on the top surface of the coke oven body 1, the carbonization chamber 34 is arranged on the inner bottom surface of the coke oven body 1, and the top surface of the rails 33 is provided with a ...

Embodiment 2

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , based on the basis of Example 1, the inner top surface of the coke oven body 1 is provided with a refractory layer 9, the top surface of the refractory layer 9 is provided with a thermal insulation layer 8, the top surface of the thermal insulation layer 8 is provided with a top brick layer 7, and the fixing groove The inner bottom surface of C5 is provided with an exhaust assembly, which is used for exhausting raw gas during the production process of the coke oven body 1. The exhaust assembly includes pipe holes 14, which are set on the inner bottom surface of the fixing groove C5, and the inside of the insulation layer 8 A flue 12 is provided, a baffle plate A3 is movably socketed on the bottom surface of the fixing groove A2, and a baffle plate B6 is movably socketed on the bottom surface of the fixing groove B4.

[0031] How it works: Please refer to Figure 1-Figure 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com